Energy Efficiency in Oil and Gas: The Role of Finned Tube Heat Exchangers

The quest for energy efficiency in the oil and gas industry is relentless, and one of the key innovations driving this is the finned tube heat exchanger. These sophisticated devices are essential in the realm of oil and gas thermal equipment, providing effective heat transfer solutions that are crucial for modern processing requirements. Introducing our Aluminum Plate Heat Exchanger, a revolutionary product designed to meet the high standards of today's industrial applications.

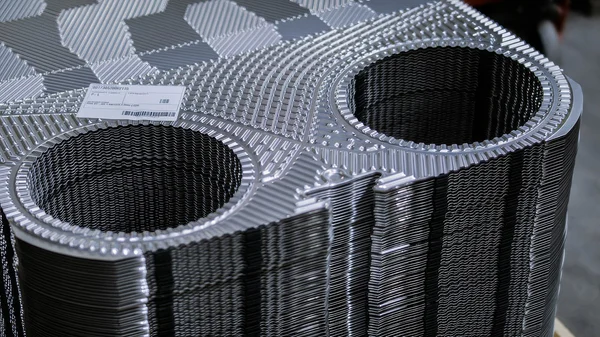

Innovative Finned Tube Technology

Our finned tube heat exchanger is at the forefront of finned tube technology, offering superior heat transfer capabilities which are indispensable for the demanding environments of oil and gas processing equipment. Crafted from high-quality aluminum, this exchanger boasts several benefits, including being lightweight, durable, and corrosion-resistant. These features make it an ideal choice for industrial finned tube exchangers, supporting both rooftop and modular installations with ease.

High-Performance and Cost-Effective Solutions

When it comes to oil and gas heat exchangers, performance and cost-effectiveness are paramount. Our product delivers on both fronts, featuring a conductivity range of 160-200 W/m·K that ensures swift heat transfer, reducing energy consumption significantly. Additionally, it is designed for long lifespan and low maintenance, with no moving parts to minimize wear and tear. The exchanger is easy to clean, further simplifying the maintenance process and ensuring consistent performance.

Customized for Versatile Applications

Understanding the diverse needs of industrial finned tube exchangers, our aluminum plate heat exchanger offers customizable configurations. With varying fin densities (5-12 FPI) and frame options ranging from galvanized steel to premium powder-coated aluminum, it can be tailored to specific project requirements. This flexibility, combined with airtight gasketing materials like EPDM or silicone, ensures optimal efficiency in various applications.

Wide-Ranging Applications in the Oil Industry

The applications of the finned tube heat exchanger extend beyond oil and gas processing equipment. They are also perfect for commercial HVAC systems, data centers, hospitals, and laboratories. For example, they play a critical role in preheating/cooling incoming fresh air in HVAC systems and managing server exhaust in data centers, cutting cooling energy consumption by up to 50%. In hospitals, these exchangers support cleanroom requirements with antimicrobial coatings and HEPA filter compatibility.

Technological Excellence

Our industry-leading Aluminum Plate Heat Exchanger is built for maximum efficiency. Made from premium aluminum plates (A6061/A3003), it endures extreme temperatures up to 150°C and manages airflow capacities from 200 to 30,000 CFM. With an impressive pressure drop range between 0.1–0.5 inH₂O, and efficiency ratings of 70–85%, it is a testament to technical excellence.

Embrace the future of energy recovery and innovation with our finned tube heat exchanger. Certified by Eurovent and ISO 9001, and compliant with LEED standards, this product promises unmatched performance and sustainability, empowering industries to achieve energy-efficient solutions without compromising on quality. Experience the seamless integration of style, functionality, and technological prowess in every application.

![[Wuxi Tenghao Machinery ] - Leading Manufacturer of Industrial Heat Exchangers](https://ptwebimg.pinshop.com/i/2025/05/29/e7pb3m-3.jpg)