The plate - fin heat exchanger is a high - efficiency heat transfer device widely used in various industrial fields. It features a

compact structure and excellent heat transfer performance, making it an ideal choice for applications where space is limited and

high heat exchange efficiency is required. This type of heat exchanger achieves heat transfer between different fluids through a

unique combination of core components, enabling precise control of temperature in processes such as heating, cooling, and heat

recovery.

Products Description

Fin-tube heat exchanger

Core Components and Their Details

2.1 Fins

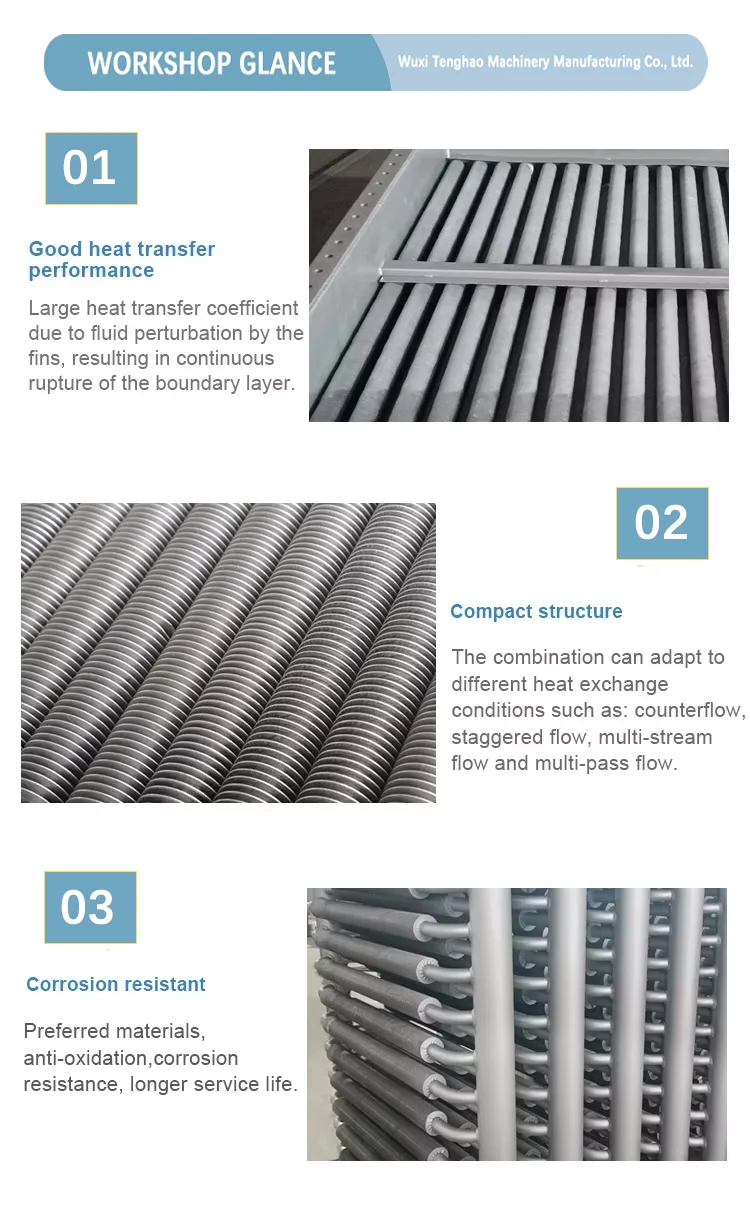

* Function: Fins are the key components for heat transfer enhancement. They significantly increase the heat transfer area,

promoting efficient heat exchange between hot and cold fluids. Different fin shapes, such as plain fins, corrugated fins, and

serrated fins, have distinct effects on fluid turbulence and heat transfer efficiency. For example, corrugated fins can enhance

fluid disturbance, thereby increasing the heat transfer coefficient.

* Materials * Aluminum Alloys (e.g., 3003, 5052, 6061): These are lightweight with good thermal conductivity (thermal conductivity ranging

from 100 - 200 W/(m·K)). They are easy to process and cost - effective, making them suitable for applications like aerospace

air - conditioning systems, industrial refrigeration units, and domestic HVAC systems where weight and cost are critical

factors.

* Copper and Copper Alloys (e.g., Pure Copper T2, Brass H62, H65, Copper - Nickel Alloys B10, B30): Pure copper has excellent

thermal conductivity (about 380 - 400 W/(m·K)). Brass offers good strength and corrosion resistance, while copper - nickel

alloys excel in corrosive environments such as seawater. They are widely used in refrigeration (evaporators and condensers

in refrigerators and freezers), marine seawater cooling systems, and high - power electronic component cooling.

* Stainless Steels (e.g., 304, 316, 316L): These provide outstanding corrosion resistance, capable of withstanding the erosion

of acids, alkalis, and chemical media. They also maintain stable mechanical properties at high temperatures. Typical

applications include chemical process heat exchange (such as in sulfuric acid and hydrochloric acid handling), food and

pharmaceutical industries (meeting hygiene and corrosion - resistance requirements), and high - temperature industrial waste

heat recovery (operating stably at 400 - 600℃ or higher).

* Titanium and Titanium Alloys (e.g., Pure Titanium TA1, TA2): They have superior corrosion resistance in harsh environments

like seawater, strong acids, and alkalis. With high strength and moderate density (about 4.5 g/cm³, 60% of stainless steel

density), they are used in marine engineering (seawater desalination equipment heat exchangers, ship power system cooling),

high - end chemical processes (handling highly corrosive and high - purity chemical materials, such as in PTA production),

and nuclear power industry auxiliary system heat exchangers.

* Function: Fins are the key components for heat transfer enhancement. They significantly increase the heat transfer area,

promoting efficient heat exchange between hot and cold fluids. Different fin shapes, such as plain fins, corrugated fins, and

serrated fins, have distinct effects on fluid turbulence and heat transfer efficiency. For example, corrugated fins can enhance

fluid disturbance, thereby increasing the heat transfer coefficient.

* Materials * Aluminum Alloys (e.g., 3003, 5052, 6061): These are lightweight with good thermal conductivity (thermal conductivity ranging

from 100 - 200 W/(m·K)). They are easy to process and cost - effective, making them suitable for applications like aerospace

air - conditioning systems, industrial refrigeration units, and domestic HVAC systems where weight and cost are critical

factors.

* Copper and Copper Alloys (e.g., Pure Copper T2, Brass H62, H65, Copper - Nickel Alloys B10, B30): Pure copper has excellent

thermal conductivity (about 380 - 400 W/(m·K)). Brass offers good strength and corrosion resistance, while copper - nickel

alloys excel in corrosive environments such as seawater. They are widely used in refrigeration (evaporators and condensers

in refrigerators and freezers), marine seawater cooling systems, and high - power electronic component cooling.

* Stainless Steels (e.g., 304, 316, 316L): These provide outstanding corrosion resistance, capable of withstanding the erosion

of acids, alkalis, and chemical media. They also maintain stable mechanical properties at high temperatures. Typical

applications include chemical process heat exchange (such as in sulfuric acid and hydrochloric acid handling), food and

pharmaceutical industries (meeting hygiene and corrosion - resistance requirements), and high - temperature industrial waste

heat recovery (operating stably at 400 - 600℃ or higher).

* Titanium and Titanium Alloys (e.g., Pure Titanium TA1, TA2): They have superior corrosion resistance in harsh environments

like seawater, strong acids, and alkalis. With high strength and moderate density (about 4.5 g/cm³, 60% of stainless steel

density), they are used in marine engineering (seawater desalination equipment heat exchangers, ship power system cooling),

high - end chemical processes (handling highly corrosive and high - purity chemical materials, such as in PTA production),

and nuclear power industry auxiliary system heat exchangers.

Video presentation

Manufacturing Technique

Performance Advantages

4.1 High Heat Transfer Efficiency

The unique structure of fins provides a large heat transfer area, and the enhanced fluid turbulence promotes efficient heat

exchange between fluids. Compared with traditional heat exchangers, it can achieve a higher heat transfer coefficient, reducing

energy consumption in heating and cooling processes.

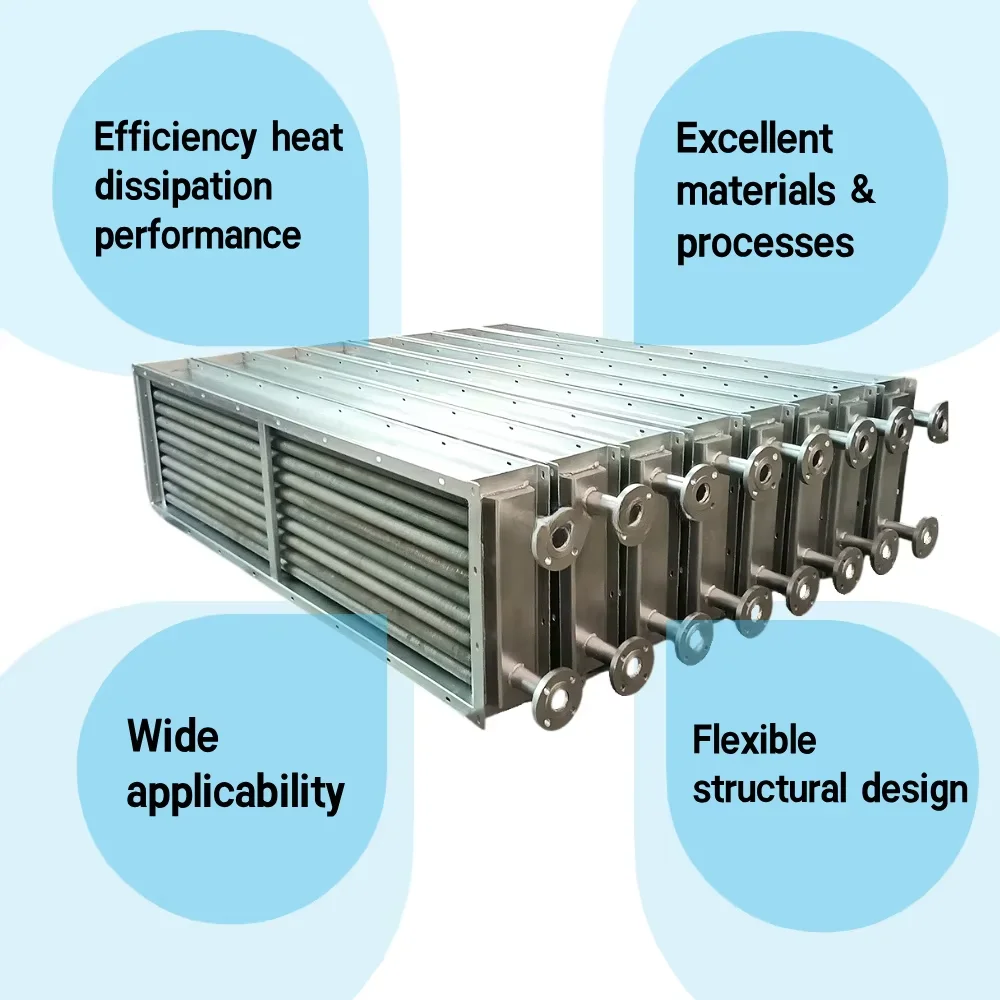

4.2 Compact Structure

With a high heat transfer area per unit volume, the plate - fin heat exchanger has a compact structure, which is especially

suitable for application scenarios with limited space, such as aerospace equipment, mobile refrigeration units, and compact

industrial process equipment.

4.3 Flexible Design

By selecting different fin shapes, materials, and channel configurations, the plate - fin heat exchanger can be customized

according to different working conditions (such as temperature, pressure, fluid properties) to meet diverse heat transfer needs.

The unique structure of fins provides a large heat transfer area, and the enhanced fluid turbulence promotes efficient heat

exchange between fluids. Compared with traditional heat exchangers, it can achieve a higher heat transfer coefficient, reducing

energy consumption in heating and cooling processes.

4.2 Compact Structure

With a high heat transfer area per unit volume, the plate - fin heat exchanger has a compact structure, which is especially

suitable for application scenarios with limited space, such as aerospace equipment, mobile refrigeration units, and compact

industrial process equipment.

4.3 Flexible Design

By selecting different fin shapes, materials, and channel configurations, the plate - fin heat exchanger can be customized

according to different working conditions (such as temperature, pressure, fluid properties) to meet diverse heat transfer needs.

Recommend Products

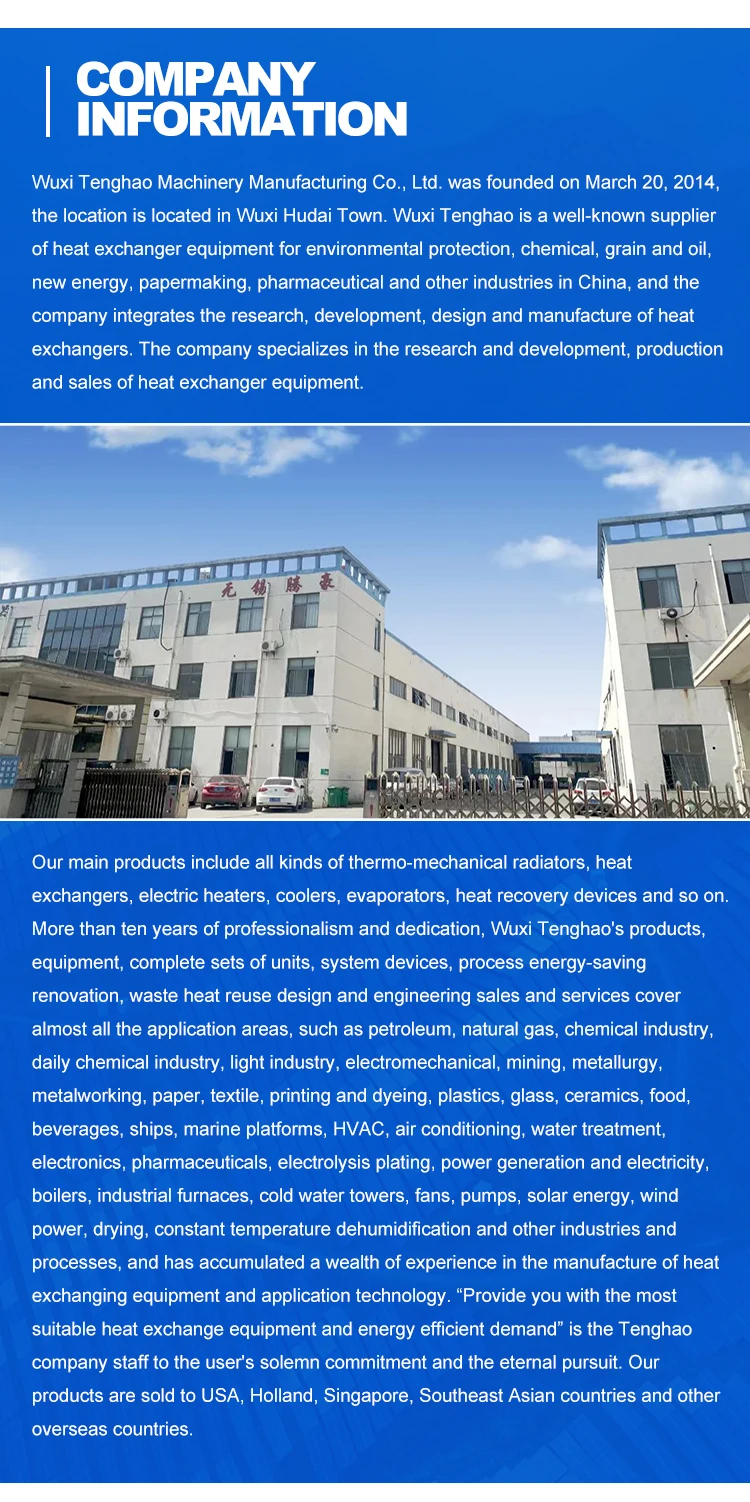

Company Profile

Product packaging

Contact information

FAQ

Q:Worry about your money? A: Trade Assurance can protect your money. (more information, pls contact me) Q: Are you trading company or manufacturer ? A: We are factory.specilizing in heat exchanger for over 10 years. Q:Are your products customized? A:Yes,the products in the website are only the common type or the previous types from other customers,we can supply the newproducts according to your requirements or drawings. Q: How long is your delivery time? A: Generally it is 10-15 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity. Q: WHY CHOOSE US? A:We have strong technical force, with more than 10 years of experience in research and development of heat exchangers,We are committed to providing our customers with the most suitable heat transfer equipment and efficient energy saving needs.