The fixed tube - sheet shell and tube heat exchanger is a fundamental and widely - used equipment in the field of heat transfer.

It features a simple yet robust structure, making it suitable for a variety of industrial applications where the temperature

difference between the tube side and shell side is relatively small or the shell - side pressure is moderate. This type of heat

exchanger plays a crucial role in processes such as heat recovery, cooling, and heating in industries like chemical, petroleum,

and HVAC.

Products Description

Tubular heat exchanger

Structural Design

Tube Bundle and Tubes

* Tube Material: Commonly available in materials like stainless steel (e.g., 304, 316), carbon steel (e.g., Q235, ASTM A106), and

sometimes copper alloys for specific corrosion - resistant or high - thermal - conductivity requirements. Stainless steel tubes

offer excellent corrosion resistance, making them ideal for handling corrosive media in chemical processes. Carbon steel tubes

are cost - effective and suitable for general industrial applications with non - corrosive or slightly corrosive fluids.

* Tube Dimensions: The outer diameter of the tubes typically ranges from 10 mm to 50 mm, and the wall thickness varies from 1 mm

to 5 mm depending on the pressure and temperature conditions. The length of the tubes can be customized, usually from 1 m to 10

m, to fit different shell sizes and heat transfer requirements.

* Tube Arrangement: Tubes are usually arranged in a triangular or square pitch pattern within the shell. Triangular pitch

provides a more compact arrangement, increasing the heat transfer area per unit shell volume, while square pitch allows for

easier cleaning and maintenance in some cases.

* Tube Material: Commonly available in materials like stainless steel (e.g., 304, 316), carbon steel (e.g., Q235, ASTM A106), and

sometimes copper alloys for specific corrosion - resistant or high - thermal - conductivity requirements. Stainless steel tubes

offer excellent corrosion resistance, making them ideal for handling corrosive media in chemical processes. Carbon steel tubes

are cost - effective and suitable for general industrial applications with non - corrosive or slightly corrosive fluids.

* Tube Dimensions: The outer diameter of the tubes typically ranges from 10 mm to 50 mm, and the wall thickness varies from 1 mm

to 5 mm depending on the pressure and temperature conditions. The length of the tubes can be customized, usually from 1 m to 10

m, to fit different shell sizes and heat transfer requirements.

* Tube Arrangement: Tubes are usually arranged in a triangular or square pitch pattern within the shell. Triangular pitch

provides a more compact arrangement, increasing the heat transfer area per unit shell volume, while square pitch allows for

easier cleaning and maintenance in some cases.

Tube Sheets

* Fixing Method: The tube sheets are welded directly to the shell and the ends of the tube bundle. This fixed connection ensures

a rigid structure but also means that thermal expansion differences between the tube bundle and the shell need to be carefully

considered.

* Material and Thickness: Tube sheets are often made of the same or compatible material as the tubes and shell. The thickness of

the tube sheets ranges from 10 mm to 50 mm, depending on the design pressure and temperature, as well as the number of tubes to

be supported.

a rigid structure but also means that thermal expansion differences between the tube bundle and the shell need to be carefully

considered.

* Material and Thickness: Tube sheets are often made of the same or compatible material as the tubes and shell. The thickness of

the tube sheets ranges from 10 mm to 50 mm, depending on the design pressure and temperature, as well as the number of tubes to

be supported.

Video presentation

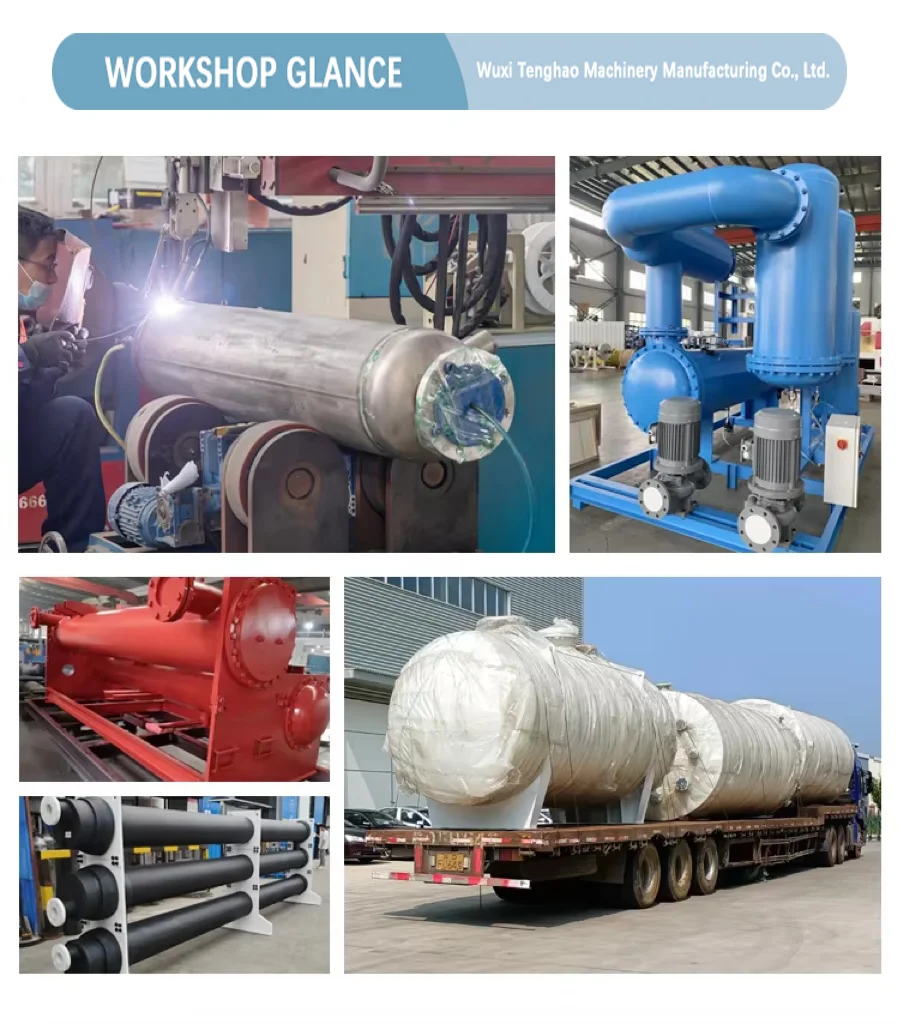

Manufacturing Technique

Performance Parameters

Heat Transfer Coefficient

* The heat transfer coefficient is a key parameter that determines the efficiency of the heat exchanger. For the fixed tube -

sheet shell and tube heat exchanger, the overall heat transfer coefficient (U - value) typically ranges from 100 W/(m²·K) to

1000 W/(m²·K). This value depends on factors such as the fluid properties (thermal conductivity, viscosity, specific heat),

flow rates of both fluids, and the cleanliness of the tube and shell surfaces.

* For example, when handling clean water on both the tube and shell sides with moderate flow rates, the U - value can be

relatively high, around 500 - 1000 W/(m²·K). However, if the fluids are viscous or contain fouling substances, the U - value

may decrease significantly, to as low as 100 - 300 W/(m²·K), due to increased thermal resistance.

* The heat transfer coefficient is a key parameter that determines the efficiency of the heat exchanger. For the fixed tube -

sheet shell and tube heat exchanger, the overall heat transfer coefficient (U - value) typically ranges from 100 W/(m²·K) to

1000 W/(m²·K). This value depends on factors such as the fluid properties (thermal conductivity, viscosity, specific heat),

flow rates of both fluids, and the cleanliness of the tube and shell surfaces.

* For example, when handling clean water on both the tube and shell sides with moderate flow rates, the U - value can be

relatively high, around 500 - 1000 W/(m²·K). However, if the fluids are viscous or contain fouling substances, the U - value

may decrease significantly, to as low as 100 - 300 W/(m²·K), due to increased thermal resistance.

Recommend Products

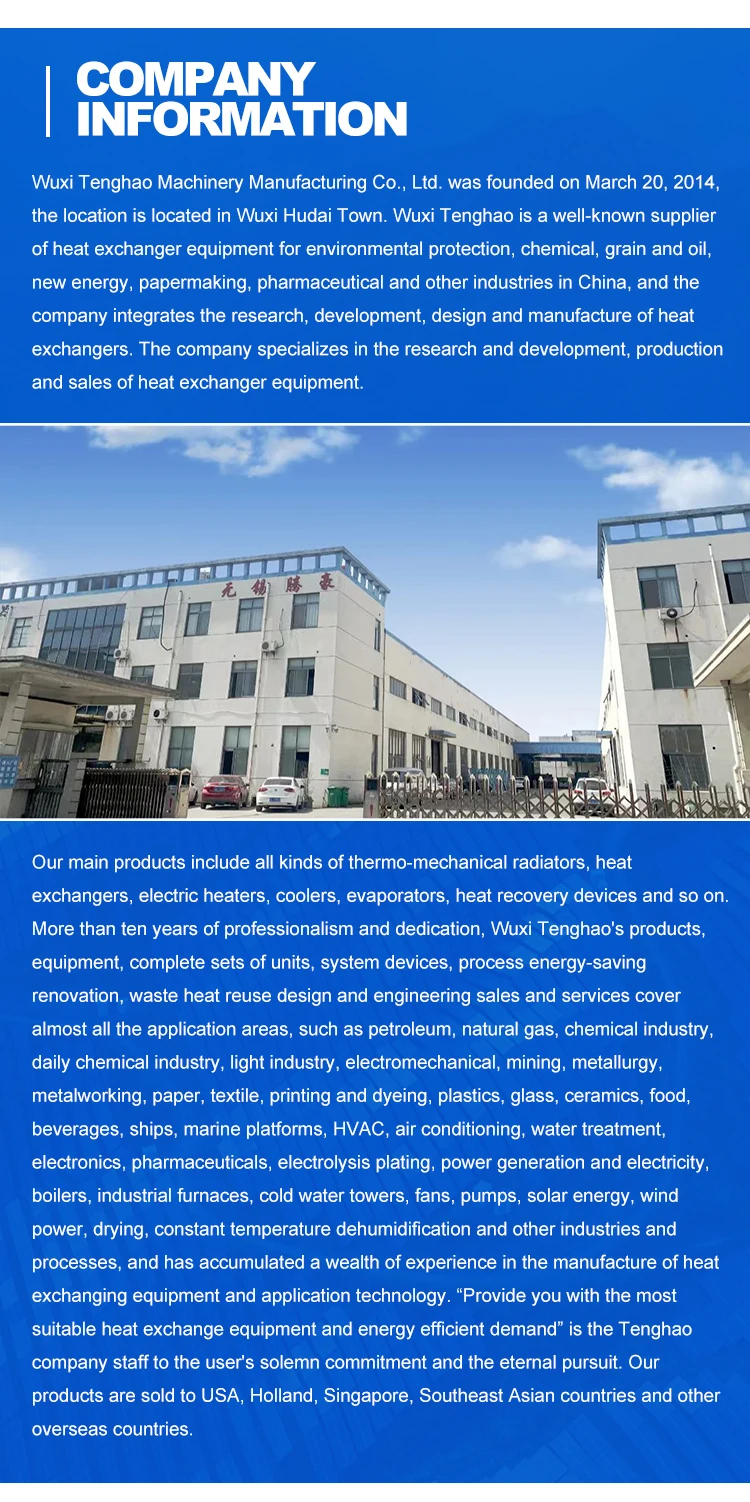

Company Profile

Product packaging

Contact information

FAQ

Q:Worry about your money? A: Trade Assurance can protect your money. (more information, pls contact me) Q: Are you trading company or manufacturer ? A: We are factory.specilizing in heat exchanger for over 10 years. Q:Are your products customized? A:Yes,the products in the website are only the common type or the previous types from other customers,we can supply the newproducts according to your requirements or drawings. Q: How long is your delivery time? A: Generally it is 10-15 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity. Q: WHY CHOOSE US? A:We have strong technical force, with more than 10 years of experience in research and development of heat exchangers,We are committed to providing our customers with the most suitable heat transfer equipment and efficient energy saving needs.