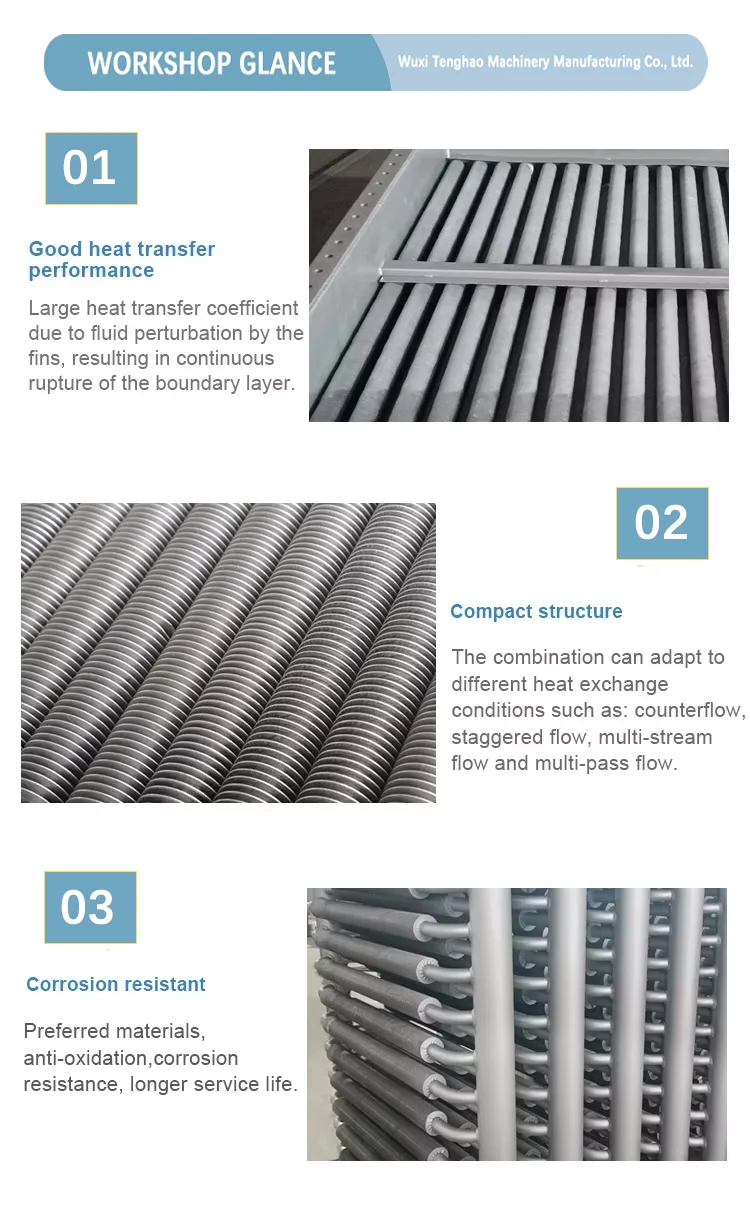

Finned tubes, as showcased, are pivotal components in heat - exchange systems. Composed of a base tube (commonly carbon steel,

stainless steel, or copper - based alloys) with fins (metal sheets like aluminum or steel) attached, they boost heat - transfer

efficiency drastically. The fins expand the heat - exchange area, enabling better thermal interaction between fluids (gases or

liquids) on either side of the tube.

Products Description

Carbon steel finned tube

Application Fields

Power Generation

* Boilers: Inside power - plant boilers, these tubes extract heat from high - temperature flue gases. The fins let the tubes

absorb more heat, heating water into steam efficiently. This steam drives turbines for electricity generation, enhancing the

plant’s thermal efficiency.

* Condensers: In condensers, finned tubes cool and condense steam back to water. The extended surface area speeds up heat release

to the cooling medium (e.g., water or air), optimizing the power - cycle and ensuring smooth plant operation.

Petrochemical Industry

* Heat Exchangers: During crude - oil distillation and chemical processing, finned tubes in heat exchangers transfer heat between

process fluids. They help separate components, control reaction temps, and boost refining efficiency, crucial for producing

fuels and chemicals.

* Reactors: In chemical reactors, they manage heat from exothermic/endothermic reactions. By effectively transferring heat, they

keep reaction conditions stable, ensuring product quality and process safety.

HVAC Systems

* Air - Handling Units: In heating/cooling coils of these units, finned tubes transfer heat between refrigerants or water and

air. This regulates indoor temp and humidity, creating a comfy environment in commercial buildings, offices, and homes.

* Radiators: Used in radiators for space heating, they release heat from hot water/steam into the air. The fins speed up heat

dispersion, warming rooms quickly and efficiently.

* Boilers: Inside power - plant boilers, these tubes extract heat from high - temperature flue gases. The fins let the tubes

absorb more heat, heating water into steam efficiently. This steam drives turbines for electricity generation, enhancing the

plant’s thermal efficiency.

* Condensers: In condensers, finned tubes cool and condense steam back to water. The extended surface area speeds up heat release

to the cooling medium (e.g., water or air), optimizing the power - cycle and ensuring smooth plant operation.

Petrochemical Industry

* Heat Exchangers: During crude - oil distillation and chemical processing, finned tubes in heat exchangers transfer heat between

process fluids. They help separate components, control reaction temps, and boost refining efficiency, crucial for producing

fuels and chemicals.

* Reactors: In chemical reactors, they manage heat from exothermic/endothermic reactions. By effectively transferring heat, they

keep reaction conditions stable, ensuring product quality and process safety.

HVAC Systems

* Air - Handling Units: In heating/cooling coils of these units, finned tubes transfer heat between refrigerants or water and

air. This regulates indoor temp and humidity, creating a comfy environment in commercial buildings, offices, and homes.

* Radiators: Used in radiators for space heating, they release heat from hot water/steam into the air. The fins speed up heat

dispersion, warming rooms quickly and efficiently.

Automotive Industry

* Engine Cooling: In car engines, finned tubes (radiator cores) dissipate heat from engine coolant to the air. This keeps the

engine at an optimal temp, preventing overheating and ensuring reliable performance.

* Heaters: For cabin heating, they transfer heat from engine coolant to air blown into the vehicle. The fins enhance heat

transfer, providing fast and effective warmth for passengers in cold weather.

engine at an optimal temp, preventing overheating and ensuring reliable performance.

* Heaters: For cabin heating, they transfer heat from engine coolant to air blown into the vehicle. The fins enhance heat

transfer, providing fast and effective warmth for passengers in cold weather.

Video presentation

Manufacturing Technique

Recommend Products

Company Profile

Product packaging

Contact information

FAQ

Q:Worry about your money? A: Trade Assurance can protect your money. (more information, pls contact me) Q: Are you trading company or manufacturer ? A: We are factory.specilizing in heat exchanger for over 10 years. Q:Are your products customized? A:Yes,the products in the website are only the common type or the previous types from other customers,we can supply the newproducts according to your requirements or drawings. Q: How long is your delivery time? A: Generally it is 10-15 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity. Q: WHY CHOOSE US? A:We have strong technical force, with more than 10 years of experience in research and development of heat exchangers,We are committed to providing our customers with the most suitable heat transfer equipment and efficient energy saving needs.