This fin - tube heat exchanger represents a cutting - edge solution for efficient heat transfer across diverse industrial,

commercial, and energy - related scenarios. Designed with precision, its core fin - tube structure enables seamless thermal

exchange between fluids (such as steam, hot water, or cooling liquids) and air. It stands as an optimal choice for temperature

regulation, energy recovery, and process optimization tasks, catering to the stringent demands of modern industrial operations and

climate control systems.

Products Description

Fin-tube heat exchanger

Core Components & Working Mechanism

* Fin - Tubes: Comprising base tubes (typically crafted from steel, stainless steel, or specialized alloys) and externally

attached fins (e.g., aluminum, copper fins). The base tubes act as conduits for heat - carrying or heat - absorbing media. The

fins, through their extended surface area, maximize air contact, accelerating heat transfer kinetics.

* Header Tanks: Fabricated from robust metal materials (carbon steel, stainless steel) with internally engineered flow channels.

These tanks ensure uniform distribution and collection of media across all fin - tubes, maintaining consistent thermal

performance and enabling hassle - free connection to external piping systems.

attached fins (e.g., aluminum, copper fins). The base tubes act as conduits for heat - carrying or heat - absorbing media. The

fins, through their extended surface area, maximize air contact, accelerating heat transfer kinetics.

* Header Tanks: Fabricated from robust metal materials (carbon steel, stainless steel) with internally engineered flow channels.

These tanks ensure uniform distribution and collection of media across all fin - tubes, maintaining consistent thermal

performance and enabling hassle - free connection to external piping systems.

Core Selling Points

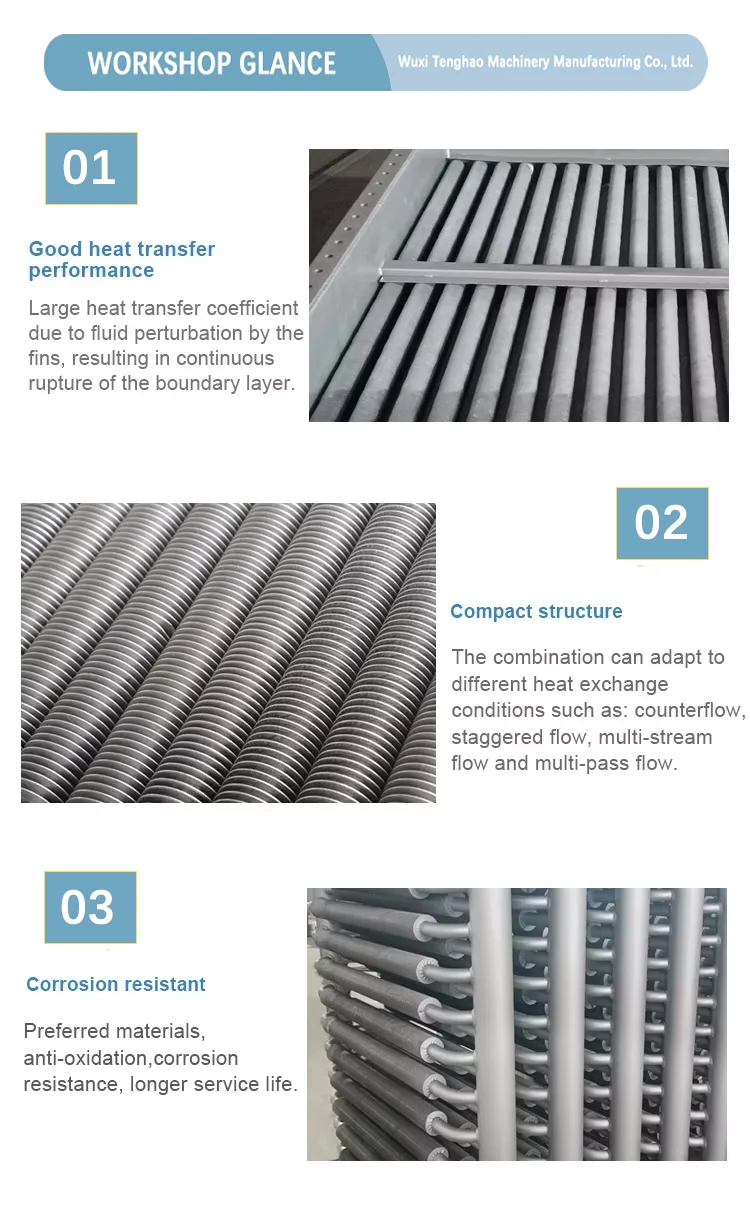

3.1 High - Efficiency Heat Transfer

The fin - tube design drastically boosts the heat - exchange area. Compared to conventional bare - tube exchangers, it achieves

faster and more thorough thermal transfer between air and fluids. This efficiency translates to reduced energy consumption,

shorter heat - exchange cycles, and enhanced system - level energy performance. Users benefit from lower operational costs and

improved process efficiency, whether heating air for industrial drying or cooling fluids in chemical processes.

3.2 Compact & Space - Saving Design

By leveraging fin - enhanced heat transfer, the exchanger delivers substantial thermal capacity within a minimal footprint. Its

compact form factor allows for flexible installation in tight spaces—be it industrial equipment rooms, commercial HVAC closets, or

modular skid - mounted systems. This adaptability minimizes space - related constraints and installation costs, making it suitable

for retrofitting into existing infrastructure.

3.3 Durability & Reliability

Constructed from high - grade, corrosion - resistant metals (stainless steel, alloy - coated steels), the exchanger withstands

harsh operating environments (high temperatures, humidity, or chemical exposure). Leak - proof header tank seals and a robust

frame design minimize risks of deformation or failure, ensuring long - term, uninterrupted operation. This reliability reduces

maintenance overheads and prevents costly production downtime.

The fin - tube design drastically boosts the heat - exchange area. Compared to conventional bare - tube exchangers, it achieves

faster and more thorough thermal transfer between air and fluids. This efficiency translates to reduced energy consumption,

shorter heat - exchange cycles, and enhanced system - level energy performance. Users benefit from lower operational costs and

improved process efficiency, whether heating air for industrial drying or cooling fluids in chemical processes.

3.2 Compact & Space - Saving Design

By leveraging fin - enhanced heat transfer, the exchanger delivers substantial thermal capacity within a minimal footprint. Its

compact form factor allows for flexible installation in tight spaces—be it industrial equipment rooms, commercial HVAC closets, or

modular skid - mounted systems. This adaptability minimizes space - related constraints and installation costs, making it suitable

for retrofitting into existing infrastructure.

3.3 Durability & Reliability

Constructed from high - grade, corrosion - resistant metals (stainless steel, alloy - coated steels), the exchanger withstands

harsh operating environments (high temperatures, humidity, or chemical exposure). Leak - proof header tank seals and a robust

frame design minimize risks of deformation or failure, ensuring long - term, uninterrupted operation. This reliability reduces

maintenance overheads and prevents costly production downtime.

Video presentation

Manufacturing Technique

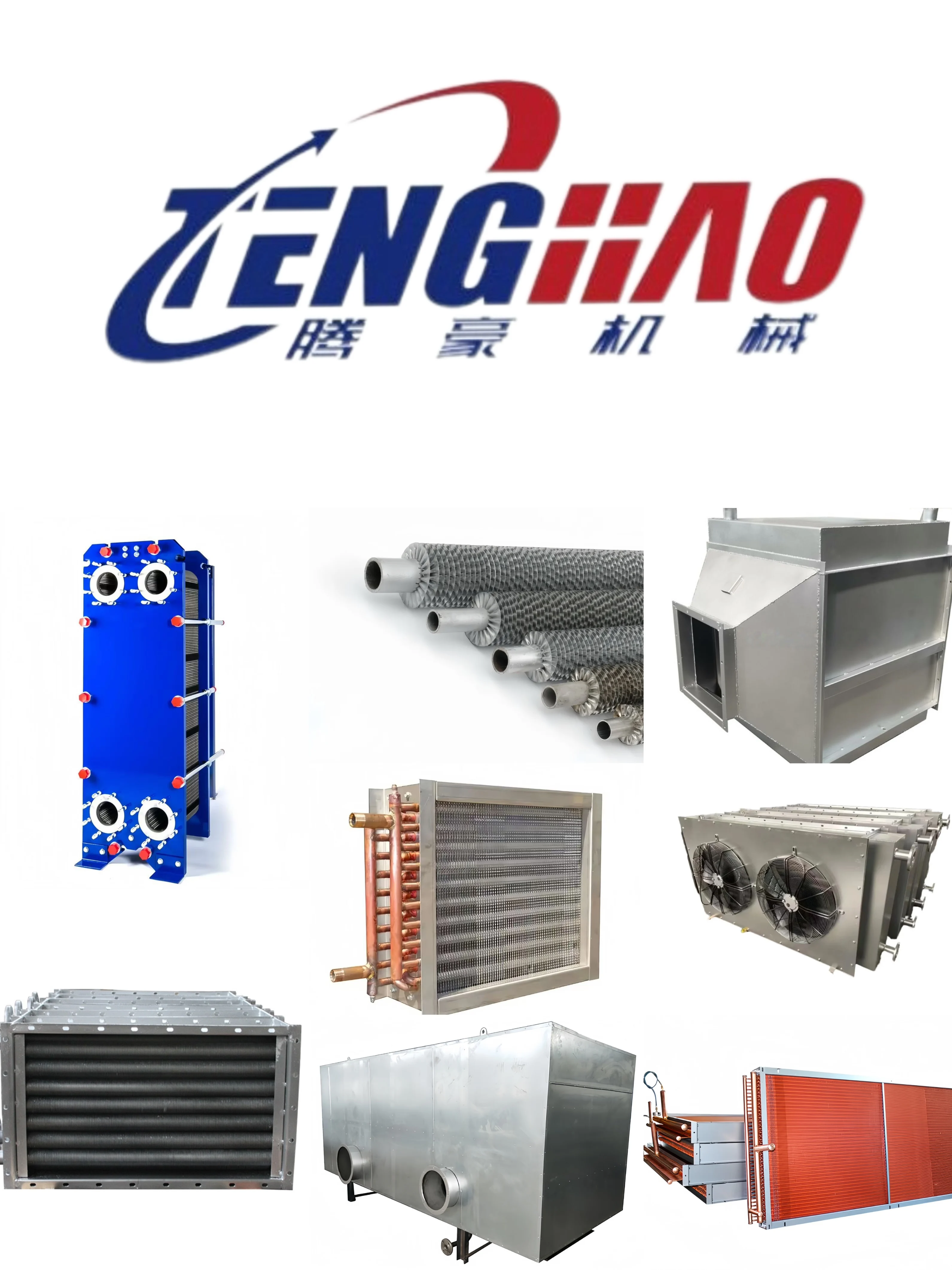

Recommend Products

Company Profile

Product packaging

Contact information

FAQ

Q:Worry about your money? A: Trade Assurance can protect your money. (more information, pls contact me) Q: Are you trading company or manufacturer ? A: We are factory.specilizing in heat exchanger for over 10 years. Q:Are your products customized? A:Yes,the products in the website are only the common type or the previous types from other customers,we can supply the newproducts according to your requirements or drawings. Q: How long is your delivery time? A: Generally it is 10-15 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity. Q: WHY CHOOSE US? A:We have strong technical force, with more than 10 years of experience in research and development of heat exchangers,We are committed to providing our customers with the most suitable heat transfer equipment and efficient energy saving needs.