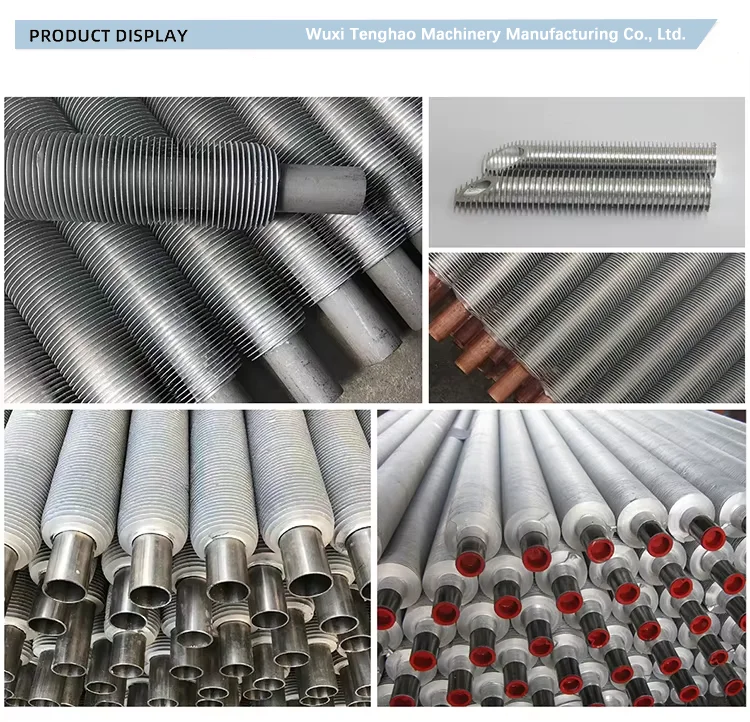

The High-Frequency Laser Welded Finned Tube is an advanced heat transfer component designed for extreme thermal efficiency,

durability, and precision performance. It utilizes high-frequency laser welding technology to bond fins seamlessly onto the base

tube, ensuring maximum heat conduction, mechanical strength, and corrosion resistance.

Products Description

High-frequency laser finned tube

Key Features

✔ Laser-welded fins – No filler material, no weak joints

✔ High thermal efficiency – 3-10x better than bare tubes

✔ Extreme durability – Resists vibration, thermal shock, and corrosion

✔ Customizable – Multiple materials, fin densities, and tube sizes

✔ High thermal efficiency – 3-10x better than bare tubes

✔ Extreme durability – Resists vibration, thermal shock, and corrosion

✔ Customizable – Multiple materials, fin densities, and tube sizes

Technical Specifications

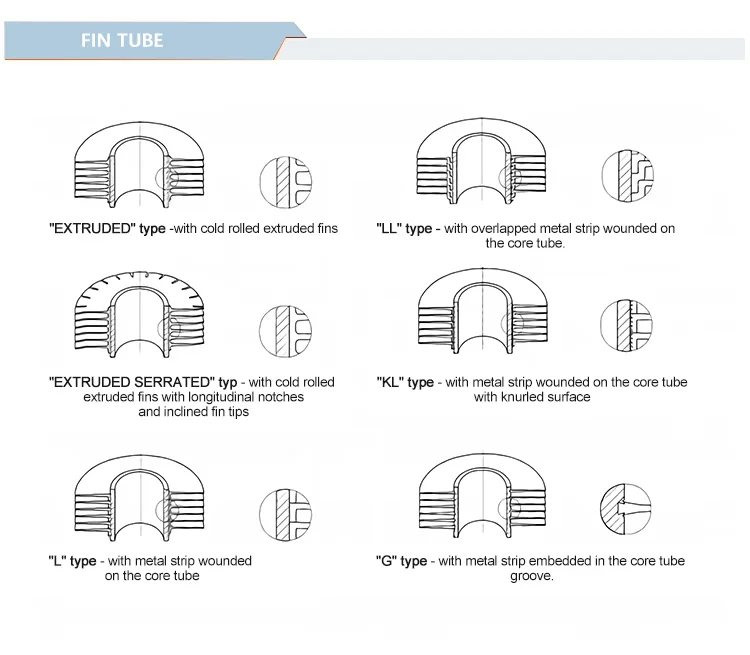

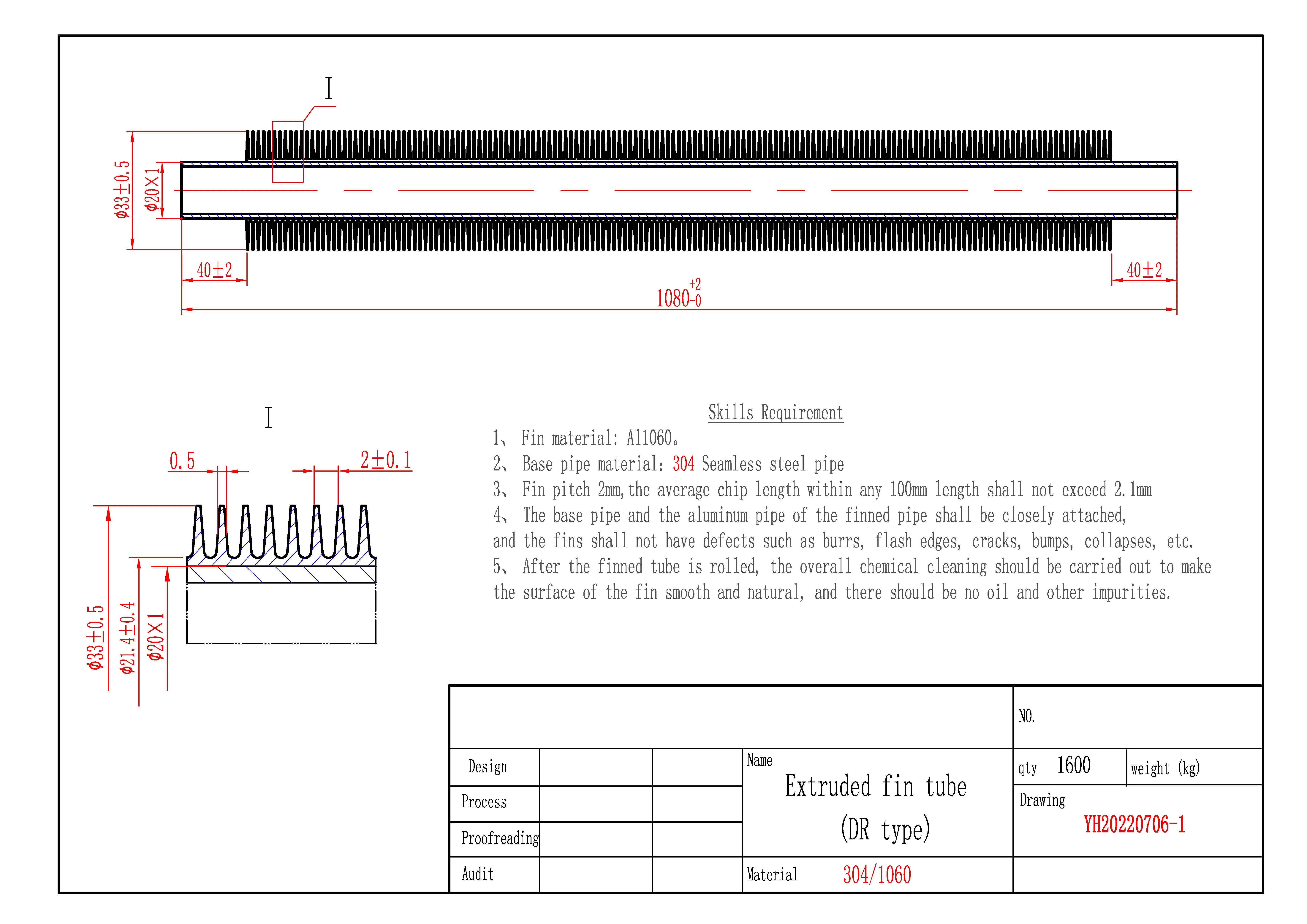

ParameterDetailsBase Tube MaterialCarbon steel, Stainless steel (304/316), Titanium, Inconel, Copper-NickelFin MaterialAluminum,

Stainless steel, Corten steel, Special alloysFin TypesSolid fins, Serrated fins, Louvered fins, Studded finsFin Height5mm – 25mm

(customizable)Fin Density3 – 12 fins per inch (FPI)Operating Temp.-200°C to +800°C (-328°F to +1472°F)Pressure RatingUp to 100 bar

(1450 psi)Welding MethodHigh-frequency laser welding (no filler metal)

Stainless steel, Corten steel, Special alloysFin TypesSolid fins, Serrated fins, Louvered fins, Studded finsFin Height5mm – 25mm

(customizable)Fin Density3 – 12 fins per inch (FPI)Operating Temp.-200°C to +800°C (-328°F to +1472°F)Pressure RatingUp to 100 bar

(1450 psi)Welding MethodHigh-frequency laser welding (no filler metal)

Key Advantages

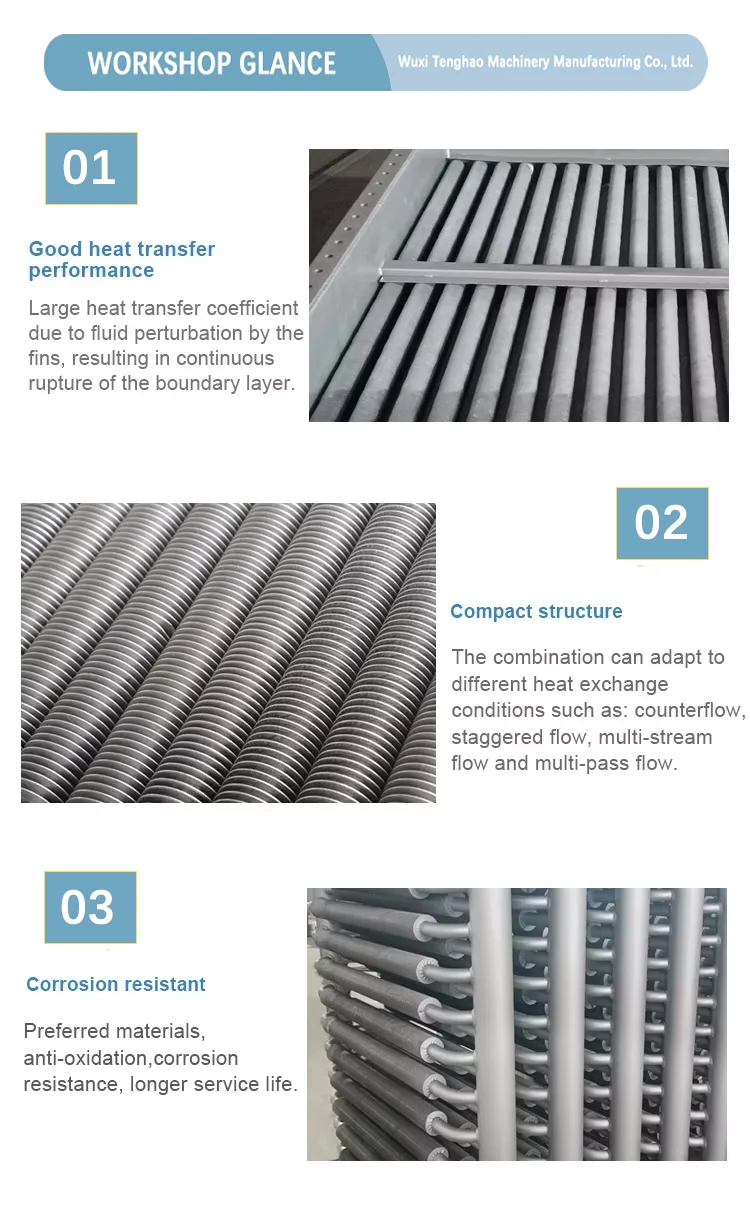

✅ Unmatched Heat Transfer Performance

* Laser welding eliminates air gaps, ensuring optimal thermal conductivity.

* Higher fin density increases surface area for better heat exchange.

✅ Superior Mechanical Strength

* No brazing or adhesives → No risk of fin loosening under vibration/thermal cycling.

* Ideal for high-pressure systems (e.g., power plants, oil & gas).

✅ Corrosion & Oxidation Resistance

* Hermetic seal prevents moisture/chemical ingress between fin and tube.

* Stainless steel & titanium options for harsh environments (e.g., marine, chemical processing).

✅ Long Service Life with Low Maintenance

* No fouling buildup due to smooth welded surfaces.

* Resists thermal fatigue better than mechanically bonded fins.

* Laser welding eliminates air gaps, ensuring optimal thermal conductivity.

* Higher fin density increases surface area for better heat exchange.

✅ Superior Mechanical Strength

* No brazing or adhesives → No risk of fin loosening under vibration/thermal cycling.

* Ideal for high-pressure systems (e.g., power plants, oil & gas).

✅ Corrosion & Oxidation Resistance

* Hermetic seal prevents moisture/chemical ingress between fin and tube.

* Stainless steel & titanium options for harsh environments (e.g., marine, chemical processing).

✅ Long Service Life with Low Maintenance

* No fouling buildup due to smooth welded surfaces.

* Resists thermal fatigue better than mechanically bonded fins.

ndustry Applications

① Oil & Gas

* Heat recovery systems (waste heat boilers, gas coolers)

* Refinery process heaters & condensers

② Power Generation

* Air-cooled condensers (ACC)

* Gas turbine inlet air cooling

③ Chemical & Petrochemical

* Reactor cooling jackets

* High-pressure heat exchangers

④ HVAC & Refrigeration

* Industrial chillers & heat pumps

* District heating networks

⑤ Marine & Offshore

* Seawater cooling systemy

* LNG heat exchangers

⑥ Renewable Energy

* Solar thermal receivers

* Geothermal heat exchangers

* Heat recovery systems (waste heat boilers, gas coolers)

* Refinery process heaters & condensers

② Power Generation

* Air-cooled condensers (ACC)

* Gas turbine inlet air cooling

③ Chemical & Petrochemical

* Reactor cooling jackets

* High-pressure heat exchangers

④ HVAC & Refrigeration

* Industrial chillers & heat pumps

* District heating networks

⑤ Marine & Offshore

* Seawater cooling systemy

* LNG heat exchangers

⑥ Renewable Energy

* Solar thermal receivers

* Geothermal heat exchangers

Why Choose Our High-Frequency Laser Finned Tubes?

* Precision manufacturing with automated laser welding for consistent quality.

* Custom engineering – Tailored to your thermal & mechanical requirements

* Global certifications (ASME, PED, ISO 9001) for reliable compliance.

* Custom engineering – Tailored to your thermal & mechanical requirements

* Global certifications (ASME, PED, ISO 9001) for reliable compliance.

Video presentation

Manufacturing Technique

Recommend Products

Company Profile

Contact information

FAQ

Q:Worry about your money? A: Trade Assurance can protect your money. (more information, pls contact me) Q: Are you trading company or manufacturer ? A: We are factory.specilizing in heat exchanger for over 10 years. Q:Are your products customized? A:Yes,the products in the website are only the common type or the previous types from other customers,we can supply the newproducts according to your requirements or drawings. Q: How long is your delivery time? A: Generally it is 10-15 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity. Q: WHY CHOOSE US? A:We have strong technical force, with more than 10 years of experience in research and development of heat exchangers,We are committed to providing our customers with the most suitable heat transfer equipment and efficient energy saving needs.