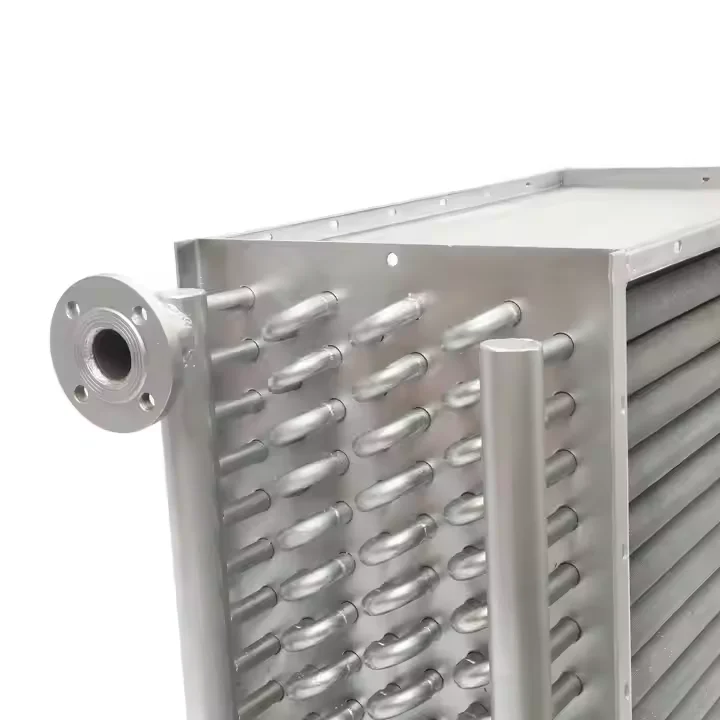

The Steel-Carbon Finned Tube Heat Exchanger is a high-efficiency thermal transfer device designed for heating, cooling, and heat

recovery applications. It consists of carbon steel tubes with externally attached fins, significantly increasing the heat exchange

surface area for improved performance in industrial and commercial systems.

Products Description

Steel-carbon finned heat exchanger

Key Features

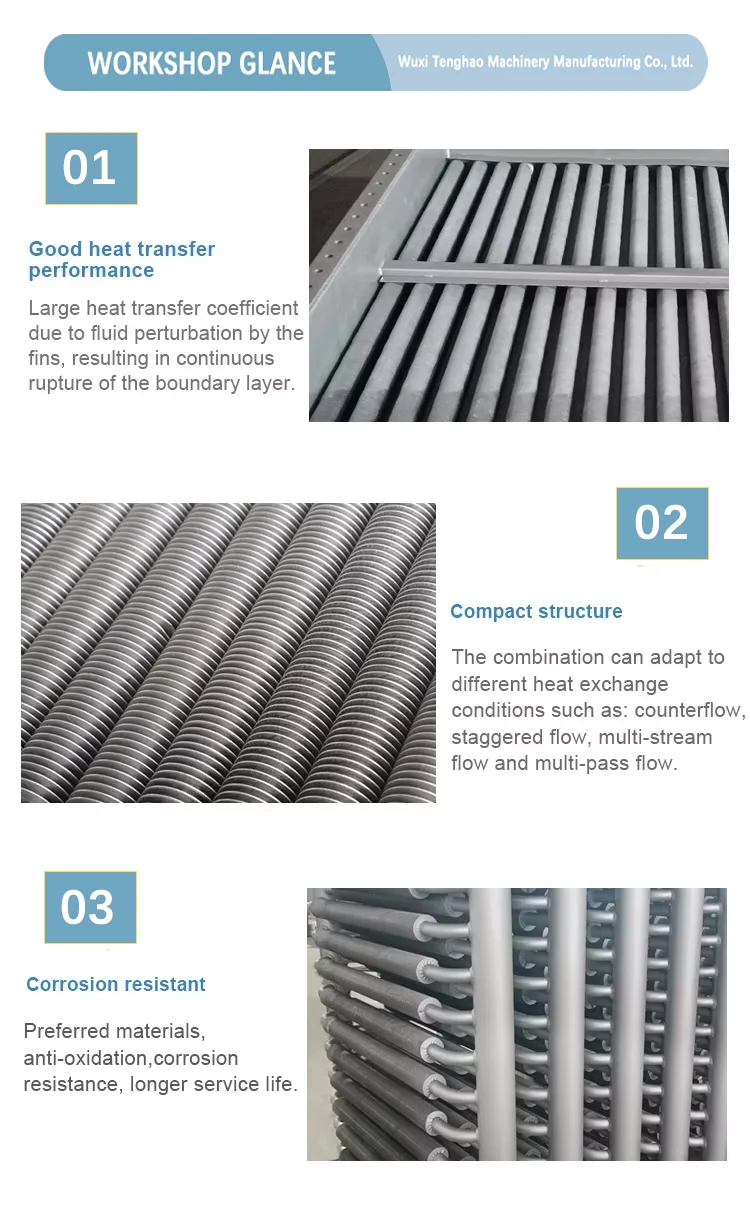

✔ High Thermal Efficiency – The finned design enhances heat transfer between fluids (gas-gas, gas-liquid, or liquid-liquid).

✔ Robust Construction – Made from carbon steel (ASTM A179/A192), providing excellent mechanical strength and durability.

✔ Cost-Effective – More economical than stainless steel or copper-nickel alternatives, while maintaining good performance in

non-corrosive environments.

✔ Versatile Applications – Suitable for air heating/cooling, waste heat recovery, and process temperature control.

✔ Customizable Designs – Available in various fin types (spiral, longitudinal, L-footed) and configurations (bare tube,

galvanized, or coated for corrosion resistance).

✔ Robust Construction – Made from carbon steel (ASTM A179/A192), providing excellent mechanical strength and durability.

✔ Cost-Effective – More economical than stainless steel or copper-nickel alternatives, while maintaining good performance in

non-corrosive environments.

✔ Versatile Applications – Suitable for air heating/cooling, waste heat recovery, and process temperature control.

✔ Customizable Designs – Available in various fin types (spiral, longitudinal, L-footed) and configurations (bare tube,

galvanized, or coated for corrosion resistance).

Applications

1. Industrial Heating & Cooling

* Air Preheaters for boilers & furnaces

* Process gas cooling in refineries & chemical plants

* Compressed air aftercoolers

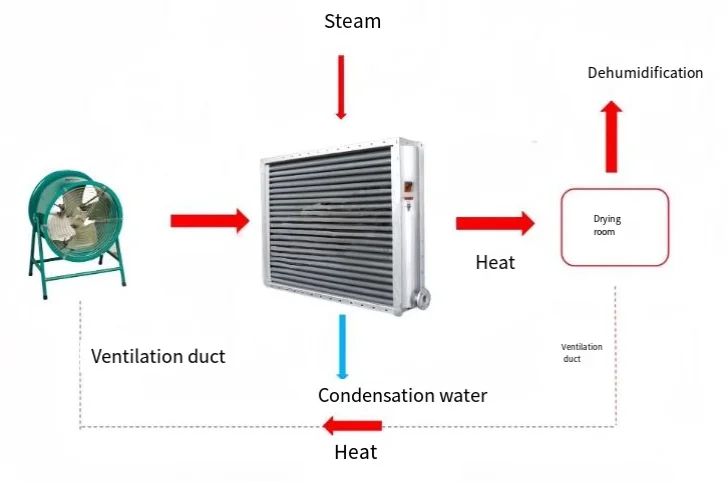

2. HVAC & Energy Recovery

* Heat recovery ventilators (HRVs)

* District heating systems

* Condensers & evaporators

3. Power & Energy

* Waste heat recovery in power plants

* Exhaust gas economizers for turbines & engines

4. Oil & Gas

* Crude oil heating in storage tanks

* Natural gas processing

* Air Preheaters for boilers & furnaces

* Process gas cooling in refineries & chemical plants

* Compressed air aftercoolers

2. HVAC & Energy Recovery

* Heat recovery ventilators (HRVs)

* District heating systems

* Condensers & evaporators

3. Power & Energy

* Waste heat recovery in power plants

* Exhaust gas economizers for turbines & engines

4. Oil & Gas

* Crude oil heating in storage tanks

* Natural gas processing

Advantages Over Plain Tube Heat Exchangers

✅ Higher heat transfer rate due to extended fin surface area.

✅ Compact design saves space compared to shell-and-tube models.

✅ Lower operational costs by improving energy efficiency.

✅ Easy maintenance with accessible finned tube bundles.

✅ Compact design saves space compared to shell-and-tube models.

✅ Lower operational costs by improving energy efficiency.

✅ Easy maintenance with accessible finned tube bundles.

Video presentation

Details Images

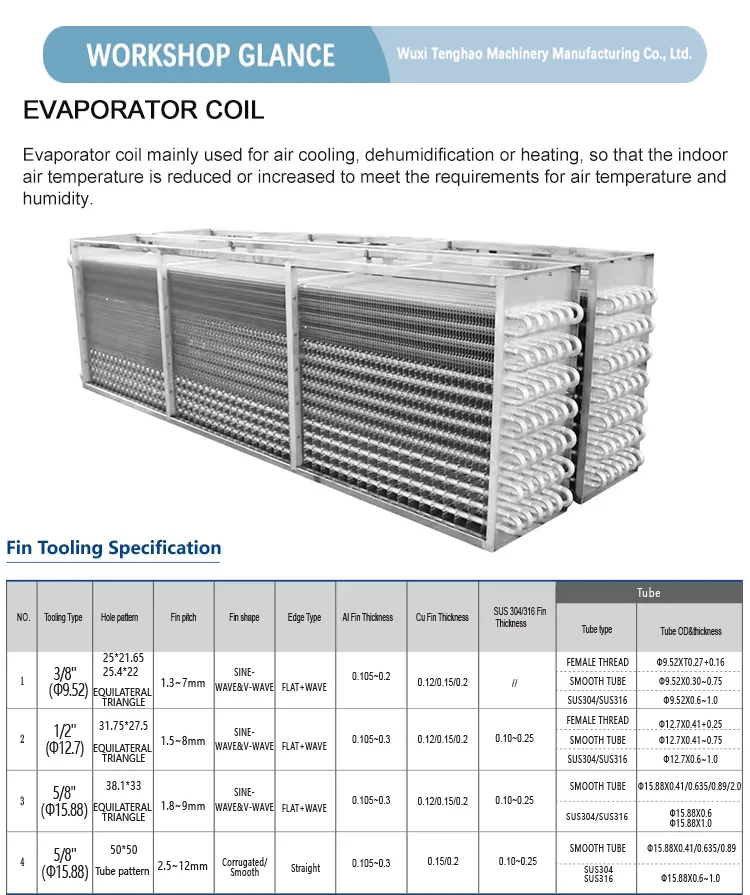

Technical Specifications

ParameterDetailsTube MaterialCarbon Steel (ASTM A179/A192)Fin MaterialCarbon Steel / Aluminium (for enhanced corrosion resistance)

Fin TypesSpiral fins, Longitudinal fins, Embedded finsFin Density3-10 fins per inch (FPI), customizableMax TemperatureUp to 400°C

(752°F) (depending on coating & medium)Pressure RatingTypically ≤ 3.0 MPa (435 psi)Connection TypesFlanged, threaded, or welded

ends

Fin TypesSpiral fins, Longitudinal fins, Embedded finsFin Density3-10 fins per inch (FPI), customizableMax TemperatureUp to 400°C

(752°F) (depending on coating & medium)Pressure RatingTypically ≤ 3.0 MPa (435 psi)Connection TypesFlanged, threaded, or welded

ends

Certifications

Product packaging

Contact information

FAQ

Q:Worry about your money? A: Trade Assurance can protect your money. (more information, pls contact me) Q: Are you trading company or manufacturer ? A: We are factory.specilizing in heat exchanger for over 10 years. Q:Are your products customized? A:Yes,the products in the website are only the common type or the previous types from other customers,we can supply the newproducts according to your requirements or drawings. Q: How long is your delivery time? A: Generally it is 10-15 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity. Q: WHY CHOOSE US? A:We have strong technical force, with more than 10 years of experience in research and development of heat exchangers,We are committed to providing our customers with the most suitable heat transfer equipment and efficient energy saving needs.