The shell - and - tube heat exchanger is a highly efficient indirect - type heat exchange equipment. With its advantages of robust

structure, strong adaptability, and large processing capacity, it is widely used in numerous industrial fields such as

petrochemical, power, refrigeration, food, and metallurgy. Through the counter - current or co - current flow of two fluids with

different temperatures in the tube side and shell side, it achieves efficient heat transfer.

Products Description

Shell-and-tube heat exchanger

Core Structure and Materials

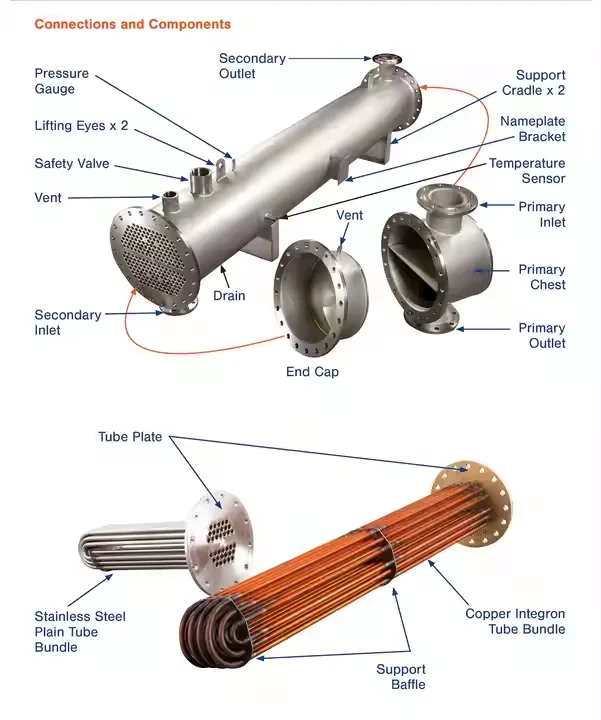

1 Core Structure

* Tube Bundle: Composed of multiple heat - exchange tubes, it is the key part for heat exchange. The heat - exchange tubes can be

arranged in various ways, such as equilateral triangle, square, and rotated square arrangements. These arrangements can

effectively increase the heat - transfer area and improve the heat - transfer efficiency.

* Shell: It provides protection and accommodation space for the tube bundle and forms the shell - side channel, allowing the

fluid to flow outside the tube bundle.

* Tube Sheet: Used to fix the two ends of the heat - exchange tubes, separating the tube side and the shell side to ensure that

the two fluids do not mix. At the same time, it undertakes the connection function between the tube bundle and the shell,

ensuring the sealing performance and structural strength of the equipment.

* Baffle: Installed in the shell side, it guides the shell - side fluid to flow along the specified path, increases the

turbulence degree of the fluid, thereby enhancing the heat - transfer effect. Meanwhile, it plays a supporting role for the

heat - exchange tubes, preventing the tube bundle from vibration and deformation.

* Head (Channel): Located at both ends of the heat exchanger, it is used for distributing and collecting the tube - side fluid.

The detachable design of some heads facilitates the inspection, cleaning, and maintenance of the tube bundle.

* Tube Bundle: Composed of multiple heat - exchange tubes, it is the key part for heat exchange. The heat - exchange tubes can be

arranged in various ways, such as equilateral triangle, square, and rotated square arrangements. These arrangements can

effectively increase the heat - transfer area and improve the heat - transfer efficiency.

* Shell: It provides protection and accommodation space for the tube bundle and forms the shell - side channel, allowing the

fluid to flow outside the tube bundle.

* Tube Sheet: Used to fix the two ends of the heat - exchange tubes, separating the tube side and the shell side to ensure that

the two fluids do not mix. At the same time, it undertakes the connection function between the tube bundle and the shell,

ensuring the sealing performance and structural strength of the equipment.

* Baffle: Installed in the shell side, it guides the shell - side fluid to flow along the specified path, increases the

turbulence degree of the fluid, thereby enhancing the heat - transfer effect. Meanwhile, it plays a supporting role for the

heat - exchange tubes, preventing the tube bundle from vibration and deformation.

* Head (Channel): Located at both ends of the heat exchanger, it is used for distributing and collecting the tube - side fluid.

The detachable design of some heads facilitates the inspection, cleaning, and maintenance of the tube bundle.

Product Advantages

* Efficient Heat Transfer: The reasonable arrangement of the tube bundle and the design of the baffle make the fluid form a good

turbulent state in the tube side and shell side, increasing the heat - transfer coefficient and effectively improving the heat

- transfer efficiency. Compared with other types of heat exchangers, under the same working conditions, the shell - and - tube

heat exchanger can achieve a higher heat - transfer rate.

* Robust Structure: The combined structure of the tube sheet, tube bundle, and shell has high strength and rigidity, and can

withstand high pressure and temperature, suitable for various complex industrial environments.

* Strong Adaptability: It can flexibly adjust the structural parameters of the heat exchanger according to different process

requirements and operating conditions, such as the diameter, length, and number of heat - exchange tubes, as well as the number

of tube sides and shell sides, to meet the heat - exchange needs under different working conditions. In addition, it can also

adapt to a variety of fluids with different properties, including corrosive, flammable, and explosive special media.

turbulent state in the tube side and shell side, increasing the heat - transfer coefficient and effectively improving the heat

- transfer efficiency. Compared with other types of heat exchangers, under the same working conditions, the shell - and - tube

heat exchanger can achieve a higher heat - transfer rate.

* Robust Structure: The combined structure of the tube sheet, tube bundle, and shell has high strength and rigidity, and can

withstand high pressure and temperature, suitable for various complex industrial environments.

* Strong Adaptability: It can flexibly adjust the structural parameters of the heat exchanger according to different process

requirements and operating conditions, such as the diameter, length, and number of heat - exchange tubes, as well as the number

of tube sides and shell sides, to meet the heat - exchange needs under different working conditions. In addition, it can also

adapt to a variety of fluids with different properties, including corrosive, flammable, and explosive special media.

Video presentation

Manufacturing Technique

Technical Parameters

* Heat - Transfer Area: Can be customized according to customer needs, ranging from several square meters to several thousand

square meters.

* Design Pressure: The design pressure of the tube side is generally 0.1 - 30MPa, and the design pressure of the shell side is

0.1 - 25MPa. It can be adjusted according to the actual working conditions.

* Design Temperature: The applicable temperature range is wide, generally - 20℃ - 450℃. Special material and structural designs

can meet higher or lower temperature requirements.

square meters.

* Design Pressure: The design pressure of the tube side is generally 0.1 - 30MPa, and the design pressure of the shell side is

0.1 - 25MPa. It can be adjusted according to the actual working conditions.

* Design Temperature: The applicable temperature range is wide, generally - 20℃ - 450℃. Special material and structural designs

can meet higher or lower temperature requirements.

Company Profile

Recommend Products

Product packaging

Contact information

FAQ

Q:Worry about your money? A: Trade Assurance can protect your money. (more information, pls contact me) Q: Are you trading company or manufacturer ? A: We are factory.specilizing in heat exchanger for over 10 years. Q:Are your products customized? A:Yes,the products in the website are only the common type or the previous types from other customers,we can supply the newproducts according to your requirements or drawings. Q: How long is your delivery time? A: Generally it is 10-15 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity. Q: WHY CHOOSE US? A:We have strong technical force, with more than 10 years of experience in research and development of heat exchangers,We are committed to providing our customers with the most suitable heat transfer equipment and efficient energy saving needs.