Our finned tube heat exchanger is a state - of - the - art thermal transfer device designed to meet the most demanding

requirements of various industries. With its advanced design and high - quality components, it offers unparalleled performance in

heat exchange applications.

Products Description

Thermal exchanger

Core Components

Copper Coils

The copper coils are the heart of our heat exchanger. Copper is chosen for its exceptional thermal conductivity, which allows for

rapid and efficient heat transfer. The coils are precisely engineered to ensure maximum contact with the fluid flowing through

them, enhancing the overall heat exchange process.

Aluminum Fins

The aluminum fins are attached to the copper coils to significantly increase the surface area available for heat transfer. These

fins are designed with a specific shape and spacing to optimize air flow and heat dissipation. The high - quality aluminum

material is resistant to corrosion, ensuring long - term durability.

Frame Structure

The frame structure provides a stable and robust support for the copper coils and fins. It is made of high - strength materials

that can withstand the rigors of transportation, installation, and operation. The frame is designed to protect the internal

components from external damage and to ensure proper alignment for efficient heat transfer.

The copper coils are the heart of our heat exchanger. Copper is chosen for its exceptional thermal conductivity, which allows for

rapid and efficient heat transfer. The coils are precisely engineered to ensure maximum contact with the fluid flowing through

them, enhancing the overall heat exchange process.

Aluminum Fins

The aluminum fins are attached to the copper coils to significantly increase the surface area available for heat transfer. These

fins are designed with a specific shape and spacing to optimize air flow and heat dissipation. The high - quality aluminum

material is resistant to corrosion, ensuring long - term durability.

Frame Structure

The frame structure provides a stable and robust support for the copper coils and fins. It is made of high - strength materials

that can withstand the rigors of transportation, installation, and operation. The frame is designed to protect the internal

components from external damage and to ensure proper alignment for efficient heat transfer.

Application Fields

HVAC Systems

In residential and commercial HVAC systems, our heat exchanger is used for both heating and cooling applications. In air

conditioners, it acts as an evaporator to absorb heat from the indoor air and as a condenser to release heat outdoors. In heat

pumps, it facilitates the transfer of heat between the indoor and outdoor environments, providing efficient temperature control.

Refrigeration Industry

For cold storage facilities, supermarkets, and other refrigeration applications, our heat exchanger helps maintain low

temperatures by removing heat from the storage space. It is an essential component in refrigeration units, ensuring the proper

preservation of perishable goods.

Industrial Cooling Systems

In industrial settings, our heat exchanger is used to cool machinery, equipment, and processes. It can be found in manufacturing

plants, data centers, and other industrial facilities where heat management is crucial for efficient operation.

HVAC Systems

In residential and commercial HVAC systems, our heat exchanger is used for both heating and cooling applications. In air

conditioners, it acts as an evaporator to absorb heat from the indoor air and as a condenser to release heat outdoors. In heat

pumps, it facilitates the transfer of heat between the indoor and outdoor environments, providing efficient temperature control.

Refrigeration Industry

For cold storage facilities, supermarkets, and other refrigeration applications, our heat exchanger helps maintain low

temperatures by removing heat from the storage space. It is an essential component in refrigeration units, ensuring the proper

preservation of perishable goods.

Industrial Cooling Systems

In industrial settings, our heat exchanger is used to cool machinery, equipment, and processes. It can be found in manufacturing

plants, data centers, and other industrial facilities where heat management is crucial for efficient operation.

Video presentation

Manufacturing Technique

Technical Specifications

ParameterSpecificationHeat Transfer Area1 - 100 m² (customizable)Tube Diameter8 - 25 mmFin Pitch1 - 5 mmWorking PressureUp to 2.5

MPaTemperature Range- 40°C to 200°CFlow Rate0.1 - 100 m³/h (customizable)

MPaTemperature Range- 40°C to 200°CFlow Rate0.1 - 100 m³/h (customizable)

Energy - Saving

The high thermal efficiency of our heat exchanger reduces energy consumption, resulting in significant cost savings for our

customers.

Compact Design

The compact design of our heat exchanger allows for easy installation in limited spaces, making it suitable for a wide range of

applications.

Customization Options

We offer a variety of customization options to meet the specific needs of our customers, including different tube diameters, fin

pitches, and heat transfer areas.

Reliable Performance

Our heat exchanger is built with high - quality materials and undergoes strict quality control measures to ensure reliable

performance and long - term durability.

The high thermal efficiency of our heat exchanger reduces energy consumption, resulting in significant cost savings for our

customers.

Compact Design

The compact design of our heat exchanger allows for easy installation in limited spaces, making it suitable for a wide range of

applications.

Customization Options

We offer a variety of customization options to meet the specific needs of our customers, including different tube diameters, fin

pitches, and heat transfer areas.

Reliable Performance

Our heat exchanger is built with high - quality materials and undergoes strict quality control measures to ensure reliable

performance and long - term durability.

Recommend Products

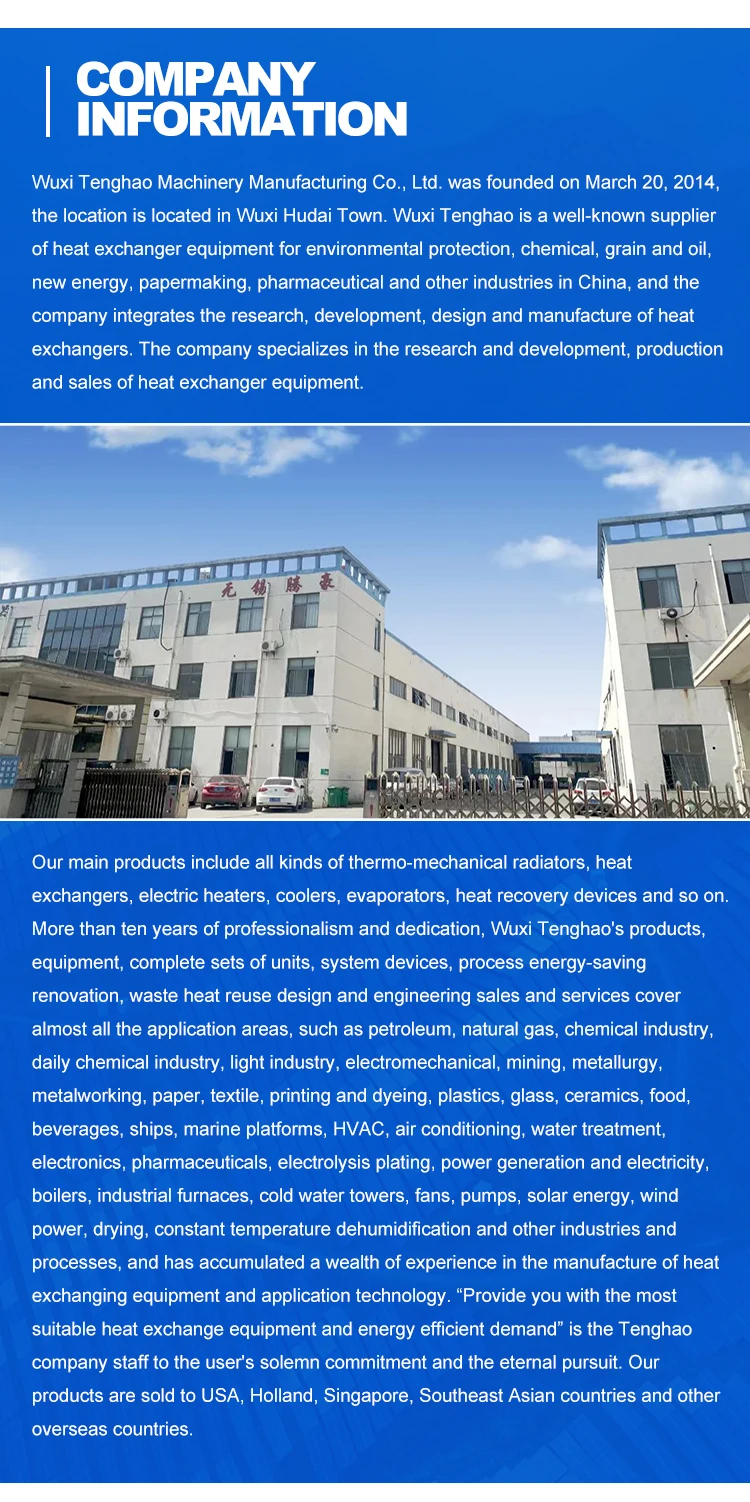

Company Profile

Product packaging

Contact information

FAQ

Q:Worry about your money? A: Trade Assurance can protect your money. (more information, pls contact me) Q: Are you trading company or manufacturer ? A: We are factory.specilizing in heat exchanger for over 10 years. Q:Are your products customized? A:Yes,the products in the website are only the common type or the previous types from other customers,we can supply the newproducts according to your requirements or drawings. Q: How long is your delivery time? A: Generally it is 10-15 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity. Q: WHY CHOOSE US? A:We have strong technical force, with more than 10 years of experience in research and development of heat exchangers,We are committed to providing our customers with the most suitable heat transfer equipment and efficient energy saving needs.