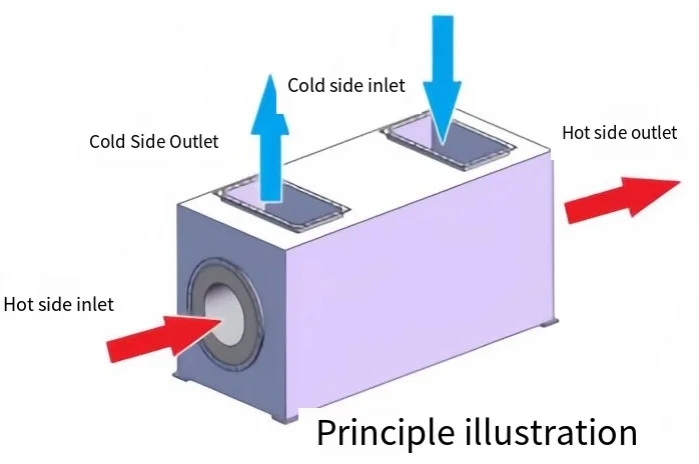

Our exhaust waste heat recovery heat exchanger is a state - of - the - art solution designed to optimize energy usage in various

industrial processes. This innovative device is engineered to capture and recycle the waste heat from exhaust gases, turning what

was once wasted energy into a valuable resource.

Products Description

Boiler energy-saving heat exchanger

Key Features

* High - Efficiency Heat Transfer: Equipped with advanced heat transfer technology, our heat exchanger can achieve an extremely

high heat transfer coefficient. The carefully designed internal structure, including finned tubes and baffles, maximizes the

contact area between the exhaust gas and the working fluid, ensuring efficient heat exchange. This results in a significant

reduction in energy consumption and operational costs.

* Robust Construction: Built with high - quality stainless steel and other corrosion - resistant materials, the heat exchanger is

highly durable and can withstand harsh industrial environments. It has excellent resistance to high temperatures, pressure, and

chemical corrosion, guaranteeing a long service life with minimal maintenance requirements.

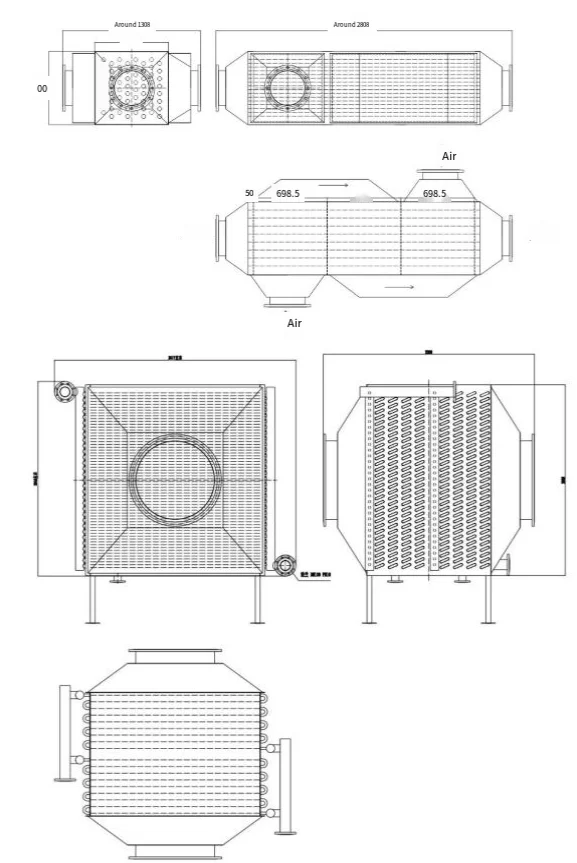

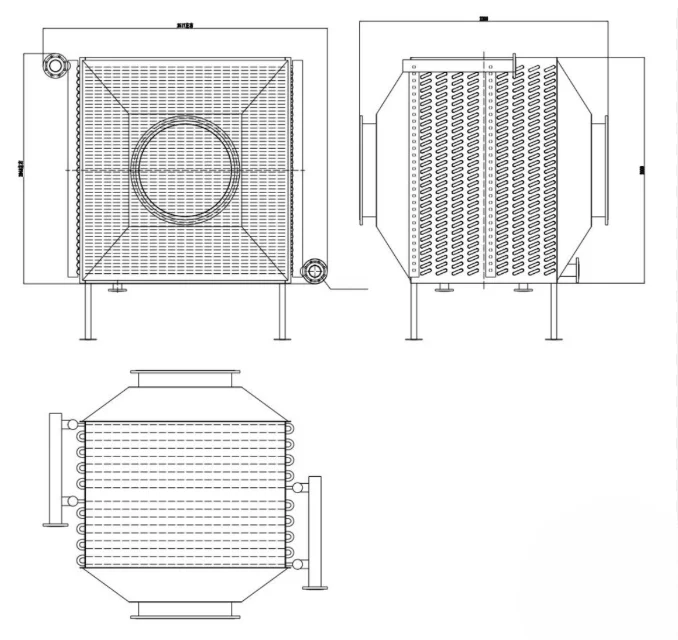

* Customizable Design: We understand that different industries have unique requirements. Therefore, our heat exchanger can be

customized in terms of size, shape, heat transfer capacity, and connection methods. Whether it is for a large - scale power

plant or a small - to - medium - sized factory, we can provide a tailored solution to meet your specific needs.

* Precise Temperature Control: The heat exchanger is equipped with a sophisticated temperature control system. This system allows

for accurate adjustment of the outlet temperature of the working fluid, ensuring stable and reliable operation of the entire

system. It can also be integrated with other industrial control systems for seamless automation.

high heat transfer coefficient. The carefully designed internal structure, including finned tubes and baffles, maximizes the

contact area between the exhaust gas and the working fluid, ensuring efficient heat exchange. This results in a significant

reduction in energy consumption and operational costs.

* Robust Construction: Built with high - quality stainless steel and other corrosion - resistant materials, the heat exchanger is

highly durable and can withstand harsh industrial environments. It has excellent resistance to high temperatures, pressure, and

chemical corrosion, guaranteeing a long service life with minimal maintenance requirements.

* Customizable Design: We understand that different industries have unique requirements. Therefore, our heat exchanger can be

customized in terms of size, shape, heat transfer capacity, and connection methods. Whether it is for a large - scale power

plant or a small - to - medium - sized factory, we can provide a tailored solution to meet your specific needs.

* Precise Temperature Control: The heat exchanger is equipped with a sophisticated temperature control system. This system allows

for accurate adjustment of the outlet temperature of the working fluid, ensuring stable and reliable operation of the entire

system. It can also be integrated with other industrial control systems for seamless automation.

Applications

* Power Generation: In power plants, it can recover waste heat from boiler flue gases, improving the overall efficiency of the

power generation process.

* Chemical Industry: It can be used to recover heat from chemical reaction exhaust gases, reducing energy consumption and

improving the economic efficiency of chemical production.

* Metallurgy: In the metallurgical industry, the heat exchanger can recover waste heat from blast furnace gases, electric arc

furnace exhaust, etc., providing pre - heated air or steam for the production process.

* Food and Beverage Industry: It can be applied to recover heat from drying processes, sterilization processes, etc., helping to

reduce energy costs and environmental impact.

power generation process.

* Chemical Industry: It can be used to recover heat from chemical reaction exhaust gases, reducing energy consumption and

improving the economic efficiency of chemical production.

* Metallurgy: In the metallurgical industry, the heat exchanger can recover waste heat from blast furnace gases, electric arc

furnace exhaust, etc., providing pre - heated air or steam for the production process.

* Food and Beverage Industry: It can be applied to recover heat from drying processes, sterilization processes, etc., helping to

reduce energy costs and environmental impact.

Video presentation

Manufacturing Technique

Benefits

* Energy Savings: By recovering and reusing waste heat, our heat exchanger can significantly reduce the consumption of primary

energy sources, such as coal, oil, and natural gas. This not only lowers energy costs but also helps to conserve natural

resources.

* Environmental Protection: Reducing energy consumption means reducing greenhouse gas emissions and other pollutants. Our heat

exchanger contributes to a cleaner and more sustainable environment by minimizing the environmental impact of industrial

processes.

energy sources, such as coal, oil, and natural gas. This not only lowers energy costs but also helps to conserve natural

resources.

* Environmental Protection: Reducing energy consumption means reducing greenhouse gas emissions and other pollutants. Our heat

exchanger contributes to a cleaner and more sustainable environment by minimizing the environmental impact of industrial

processes.

Recommend Products

Company Profile

Product packaging

Contact information

FAQ

Q:Worry about your money? A: Trade Assurance can protect your money. (more information, pls contact me) Q: Are you trading company or manufacturer ? A: We are factory.specilizing in heat exchanger for over 10 years. Q:Are your products customized? A:Yes,the products in the website are only the common type or the previous types from other customers,we can supply the newproducts according to your requirements or drawings. Q: How long is your delivery time? A: Generally it is 10-15 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity. Q: WHY CHOOSE US? A:We have strong technical force, with more than 10 years of experience in research and development of heat exchangers,We are committed to providing our customers with the most suitable heat transfer equipment and efficient energy saving needs.