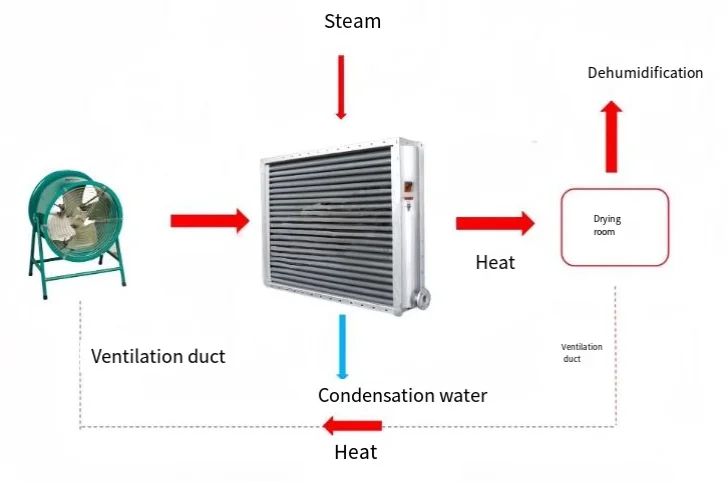

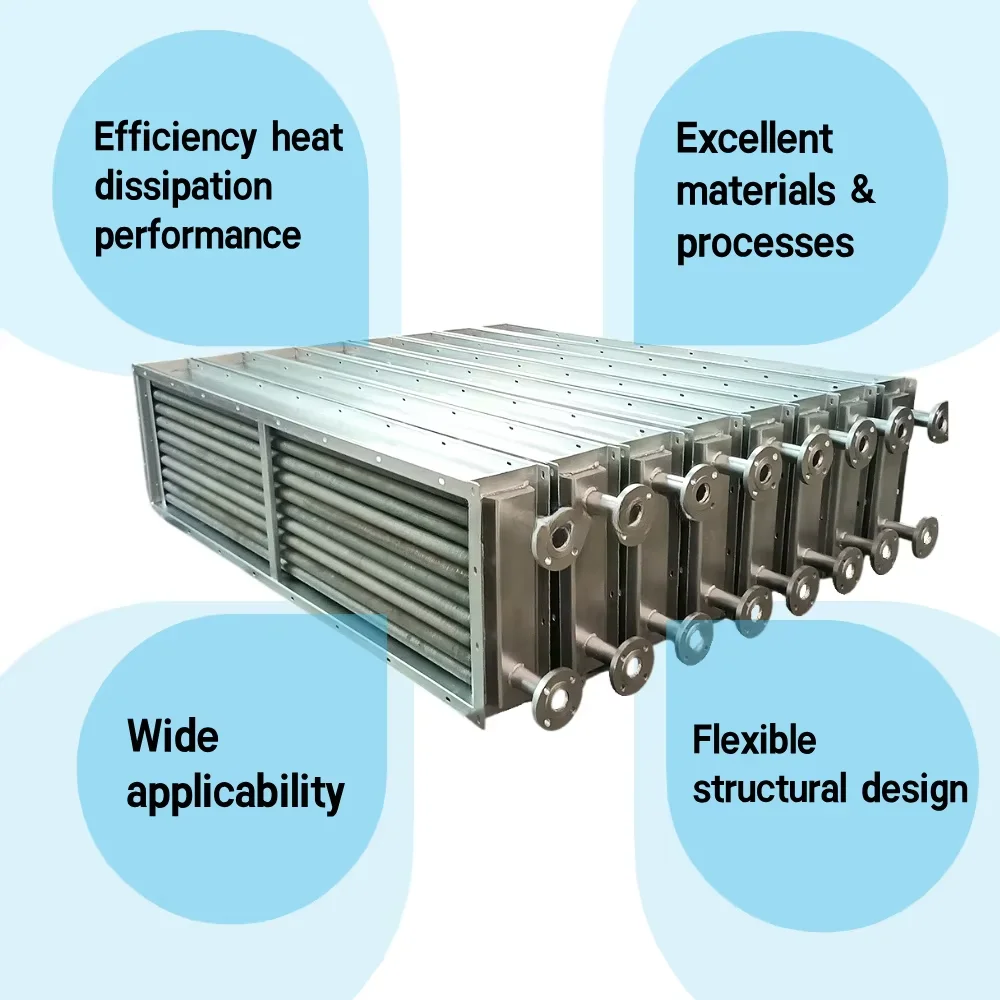

Our industrial drying finned tube heat exchangaer is a cutting - edge solution engineered to supercharge drying processes across

diverse sectors. Built with precision and robust materials, it excels at rapid heat transfer, ensuring consistent, high -

efficiency drying for bulk materials, whether in food production, chemical processing, or other industrial applications.

Products Description

Industrial drying finned tube heat exchanger

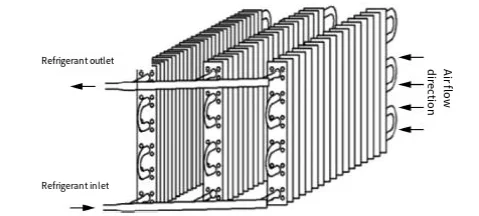

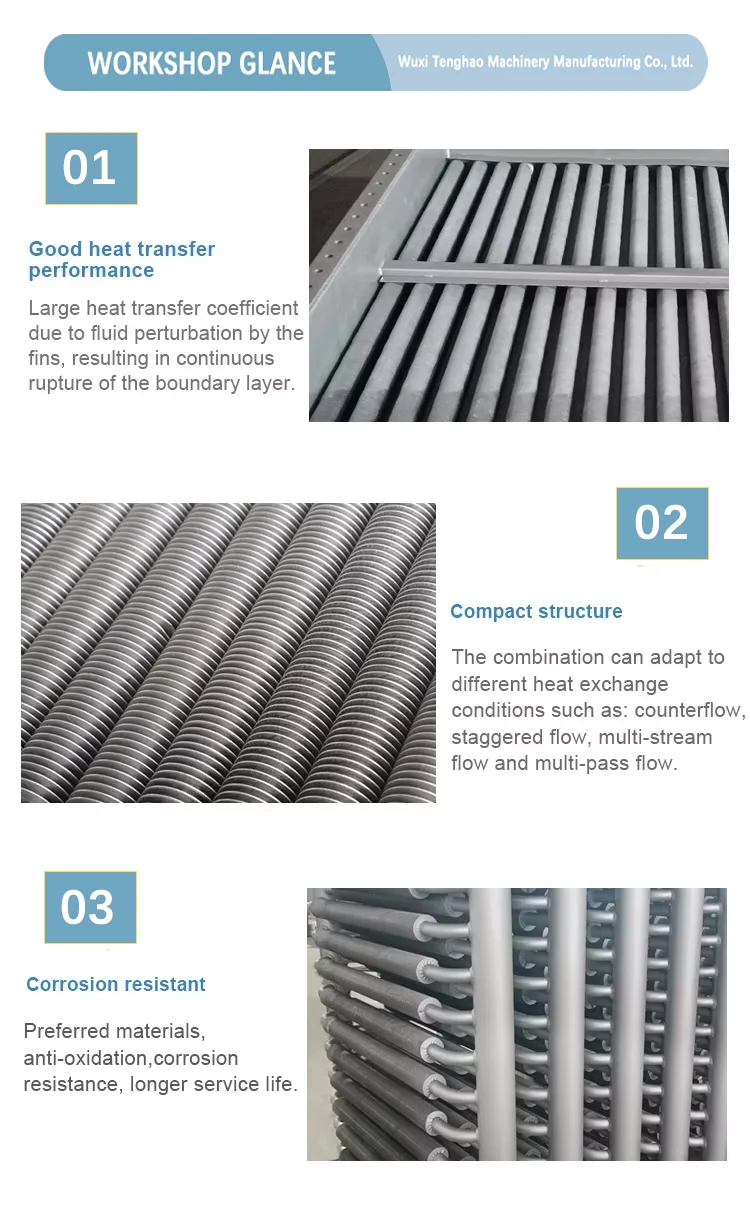

Finned Tubes: The Heat - Transfer Powerhouse

* Tube Structure: Premium - grade base tubes (carbon steel, stainless steel like 304/316L, or copper) form the core, channeling

heat - carrying media (steam, thermal oil, hot water). These tubes boast excellent thermal conductivity and pressure

resistance.

* Fin Design: High - performance fins (aluminum, steel, or copper - aluminum composite) wrap around the base tubes. With shapes

like spiral, corrugated, or plain fins, they maximize the heat - exchange area (up to 3–5 times that of smooth tubes). This

design accelerates heat dissipation into the drying air, slashing drying cycles.

heat - carrying media (steam, thermal oil, hot water). These tubes boast excellent thermal conductivity and pressure

resistance.

* Fin Design: High - performance fins (aluminum, steel, or copper - aluminum composite) wrap around the base tubes. With shapes

like spiral, corrugated, or plain fins, they maximize the heat - exchange area (up to 3–5 times that of smooth tubes). This

design accelerates heat dissipation into the drying air, slashing drying cycles.

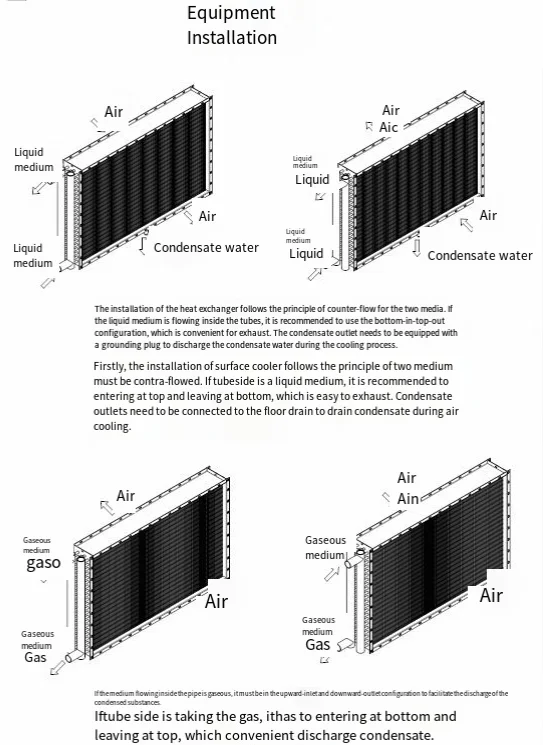

Modular & Adaptable Framework

The exchanger features a modular structure, allowing easy customization of size, fin density, and material combinations. Whether

your drying line needs compact units for space - constrained setups or large - scale systems for high - throughput operations, it

adapts seamlessly.

your drying line needs compact units for space - constrained setups or large - scale systems for high - throughput operations, it

adapts seamlessly.

Key Selling Points

1. Ultra - Efficient Heat Exchange

Thanks to the finned design, heat transfer efficiency skyrockets. It rapidly elevates the temperature of drying air, enabling

faster moisture evaporation from materials. For example, in food dehydration, it cuts drying time for fruits/vegetables by 30–40%,

boosting production throughput.

2. Energy - Smart Operation

By minimizing heat loss and maximizing thermal utilization, our exchanger slashes energy consumption. The optimized fin - tube

interaction ensures more heat is directed to drying, reducing reliance on costly heat sources (e.g., steam, electricity) and

lowering operational costs long - term.

3. Tough & Long - Lasting

Crafted from durable materials (corrosion - resistant stainless steel for harsh chemical environments; high - strength steel for

high - temperature drying), it withstands extreme conditions—high temps, humidity, and corrosive gases. Precision manufacturing

(e.g., high - frequency welding for tight fin - tube bonding) ensures shock and wear resistance, delivering a service life of 10+

years with minimal maintenance.

4. Versatile Across Industries

* Food Processing: Ideal for drying grains, fruits, meats, and spices. Meets food - grade hygiene standards (stainless steel

options), ensuring product safety.

* Chemical & Pharmaceutical: Handles drying of chemicals, pharmaceuticals, and additives, resisting corrosion from aggressive

media.

* Textile & Woodworking: Efficiently dries fabrics, yarns, and lumber, preventing warping/cracking with precise temperature

control.

* Agriculture: Perfect for drying seeds, fertilizers, and agricultural by - products, enhancing storage stability.

Thanks to the finned design, heat transfer efficiency skyrockets. It rapidly elevates the temperature of drying air, enabling

faster moisture evaporation from materials. For example, in food dehydration, it cuts drying time for fruits/vegetables by 30–40%,

boosting production throughput.

2. Energy - Smart Operation

By minimizing heat loss and maximizing thermal utilization, our exchanger slashes energy consumption. The optimized fin - tube

interaction ensures more heat is directed to drying, reducing reliance on costly heat sources (e.g., steam, electricity) and

lowering operational costs long - term.

3. Tough & Long - Lasting

Crafted from durable materials (corrosion - resistant stainless steel for harsh chemical environments; high - strength steel for

high - temperature drying), it withstands extreme conditions—high temps, humidity, and corrosive gases. Precision manufacturing

(e.g., high - frequency welding for tight fin - tube bonding) ensures shock and wear resistance, delivering a service life of 10+

years with minimal maintenance.

4. Versatile Across Industries

* Food Processing: Ideal for drying grains, fruits, meats, and spices. Meets food - grade hygiene standards (stainless steel

options), ensuring product safety.

* Chemical & Pharmaceutical: Handles drying of chemicals, pharmaceuticals, and additives, resisting corrosion from aggressive

media.

* Textile & Woodworking: Efficiently dries fabrics, yarns, and lumber, preventing warping/cracking with precise temperature

control.

* Agriculture: Perfect for drying seeds, fertilizers, and agricultural by - products, enhancing storage stability.

Video presentation

Manufacturing Technique

Application Scenarios

* Batch Drying: Small - to medium - scale operations (e.g., artisanal food production, lab - scale chemical drying).

* Continuous Flow Drying: Large - volume industrial lines (e.g., textile factories, wood processing plants), integrating with

conveyor systems for non - stop drying.

* Harsh Environments: Chemical plants (corrosive gases), offshore drying units (saltwater corrosion)—stainless steel models

thrive here.

* Continuous Flow Drying: Large - volume industrial lines (e.g., textile factories, wood processing plants), integrating with

conveyor systems for non - stop drying.

* Harsh Environments: Chemical plants (corrosive gases), offshore drying units (saltwater corrosion)—stainless steel models

thrive here.

Technical Specifications (Customizable)

ParameterRangeBase Tube MaterialCarbon Steel, SS304/316L, CopperFin MaterialAluminum, Steel, Copper - AluminumHeat MediaSteam,

Thermal Oil, Hot WaterOperating Temp.- 20℃–600℃ (varies by material)Pressure RatingUp to 25MPa (customizable)Fin TypesSpiral,

Corrugated, Plain

Thermal Oil, Hot WaterOperating Temp.- 20℃–600℃ (varies by material)Pressure RatingUp to 25MPa (customizable)Fin TypesSpiral,

Corrugated, Plain

Recommend Products

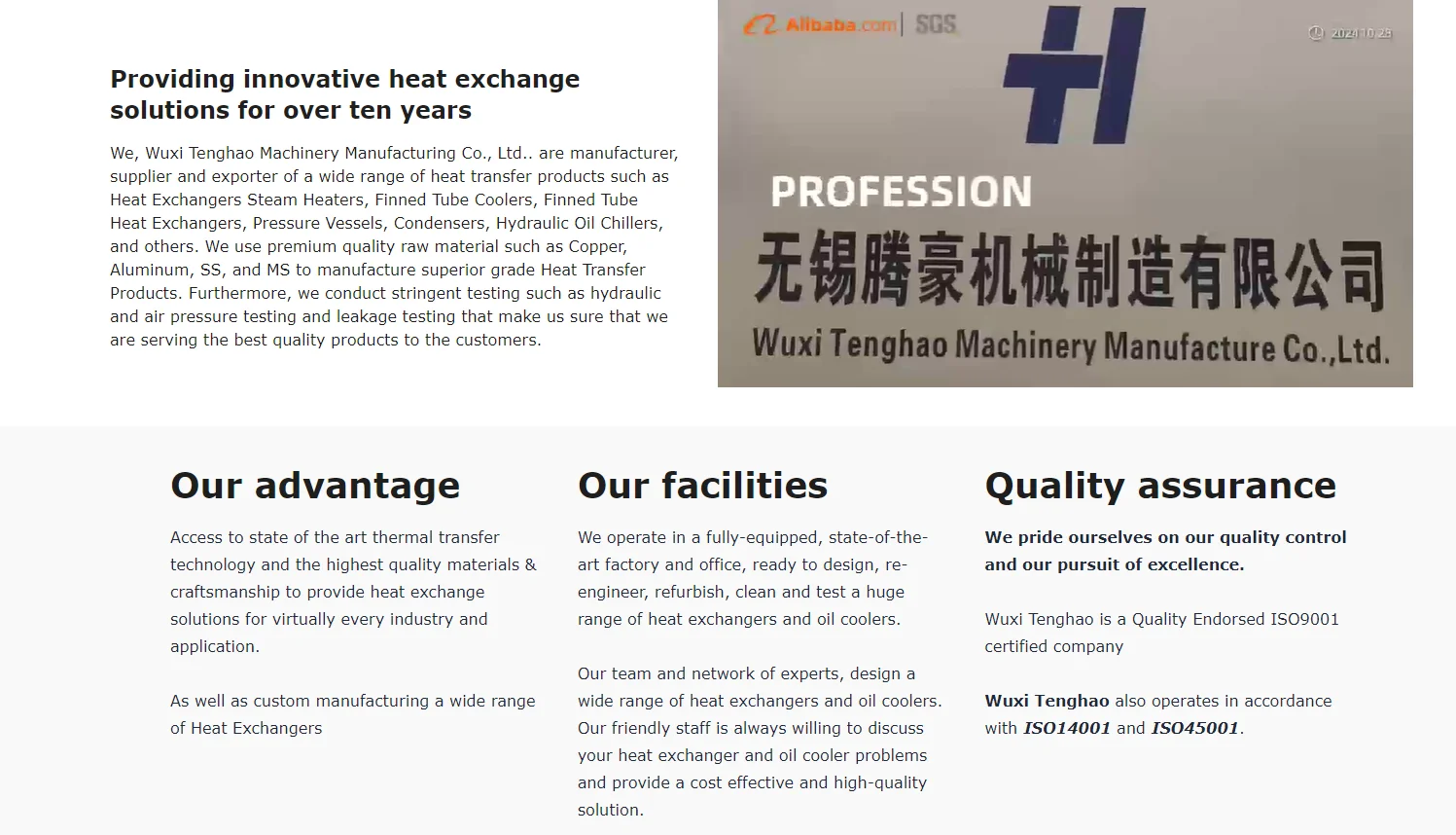

Company Profile

Contact information

FAQ

Q:Worry about your money? A: Trade Assurance can protect your money. (more information, pls contact me) Q: Are you trading company or manufacturer ? A: We are factory.specilizing in heat exchanger for over 10 years. Q:Are your products customized? A:Yes,the products in the website are only the common type or the previous types from other customers,we can supply the newproducts according to your requirements or drawings. Q: How long is your delivery time? A: Generally it is 10-15 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity. Q: WHY CHOOSE US? A:We have strong technical force, with more than 10 years of experience in research and development of heat exchangers,We are committed to providing our customers with the most suitable heat transfer equipment and efficient energy saving needs.