Our high - frequency welded fin tubes are precision - engineered heat - exchange components, playing a crucial role in enhancing

thermal transfer efficiency across diverse industrial applications. These tubes feature fins firmly attached to the base tube via

advanced high - frequency welding technology, ensuring superior structural integrity and heat - transfer performance.

Products Description

High-frequency laser finned tube

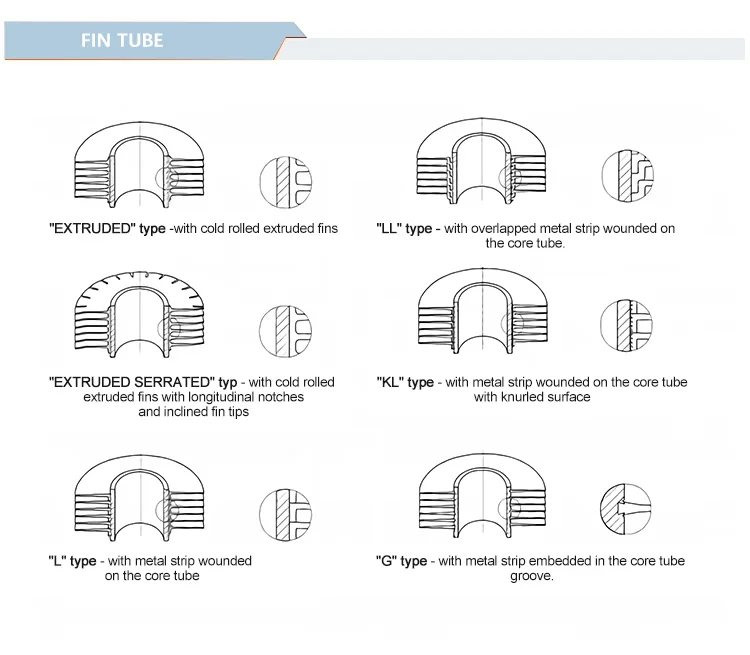

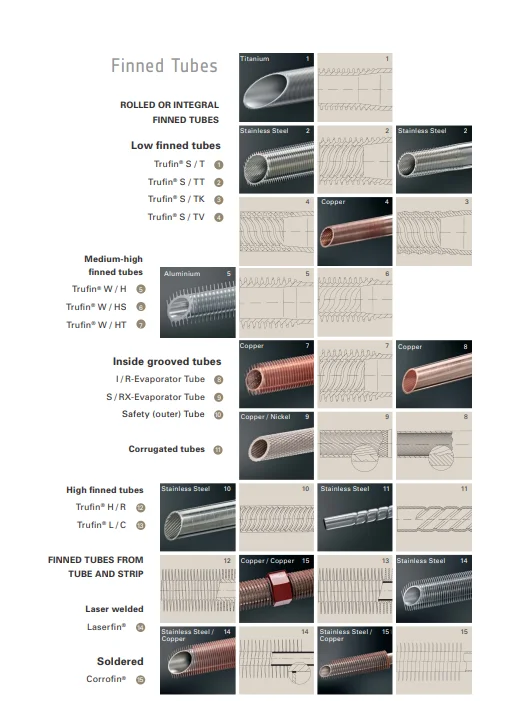

Construction and Technology

1. Base Tube * Available in various materials such as carbon steel, stainless steel (e.g., 304, 316), and copper alloys. The

selection depends on specific application requirements like corrosion resistance, temperature, and pressure conditions. For

instance, stainless steel base tubes are ideal for acidic or high - salinity environments in chemical processing, while

copper alloys suit HVAC systems demanding excellent thermal conductivity.

* Precisely manufactured to strict dimensional tolerances, ensuring a smooth inner surface for unimpeded fluid flow,

which is vital for maintaining consistent heat - transfer rates.

2. Fins * Typically made from materials matching or complementary to the base tube for optimal thermal compatibility. Common fin

materials include aluminum (for its high thermal conductivity and lightweight nature, perfect for HVAC and refrigeration),

carbon steel (cost - effective for general industrial heating), and stainless steel (for harsh, corrosive environments).

* The fin shape is usually helical, maximizing the surface area exposed to the surrounding medium (air or other heat -

exchange fluids). This helical design also promotes turbulent flow, disrupting boundary layers and enhancing heat transfer.

selection depends on specific application requirements like corrosion resistance, temperature, and pressure conditions. For

instance, stainless steel base tubes are ideal for acidic or high - salinity environments in chemical processing, while

copper alloys suit HVAC systems demanding excellent thermal conductivity.

* Precisely manufactured to strict dimensional tolerances, ensuring a smooth inner surface for unimpeded fluid flow,

which is vital for maintaining consistent heat - transfer rates.

2. Fins * Typically made from materials matching or complementary to the base tube for optimal thermal compatibility. Common fin

materials include aluminum (for its high thermal conductivity and lightweight nature, perfect for HVAC and refrigeration),

carbon steel (cost - effective for general industrial heating), and stainless steel (for harsh, corrosive environments).

* The fin shape is usually helical, maximizing the surface area exposed to the surrounding medium (air or other heat -

exchange fluids). This helical design also promotes turbulent flow, disrupting boundary layers and enhancing heat transfer.

Performance Advantages

1. High Heat - Transfer Efficiency * The increased surface area provided by the fins, combined with the efficient thermal

connection from high - frequency welding, allows for significantly enhanced heat exchange. In heat exchanger applications,

this means faster heating or cooling of fluids, reducing energy consumption and operational costs. For example, in a steam

- to - air heat exchanger, our fin tubes can achieve heat transfer coefficients that are [X]% higher than standard plain

tubes, leading to more compact and cost - effective heat exchanger designs.

* The turbulent flow promotion by the helical fins further boosts heat transfer by minimizing

the thickness of the thermal boundary layer, ensuring that the fluid temperatures are quickly and evenly adjusted.

2. Durability and Longevity * The metallurgical bond from high - frequency welding ensures excellent resistance to thermal

stress, which is critical in applications with frequent temperature fluctuations (e.g., industrial boilers, refrigeration

systems). Unlike mechanically bonded fins that may loosen over time due to thermal expansion and contraction, our welded

fins remain securely attached, maintaining consistent performance over the product's lifespan.

connection from high - frequency welding, allows for significantly enhanced heat exchange. In heat exchanger applications,

this means faster heating or cooling of fluids, reducing energy consumption and operational costs. For example, in a steam

- to - air heat exchanger, our fin tubes can achieve heat transfer coefficients that are [X]% higher than standard plain

tubes, leading to more compact and cost - effective heat exchanger designs.

* The turbulent flow promotion by the helical fins further boosts heat transfer by minimizing

the thickness of the thermal boundary layer, ensuring that the fluid temperatures are quickly and evenly adjusted.

2. Durability and Longevity * The metallurgical bond from high - frequency welding ensures excellent resistance to thermal

stress, which is critical in applications with frequent temperature fluctuations (e.g., industrial boilers, refrigeration

systems). Unlike mechanically bonded fins that may loosen over time due to thermal expansion and contraction, our welded

fins remain securely attached, maintaining consistent performance over the product's lifespan.

Video presentation

Manufacturing Technique

Recommend Products

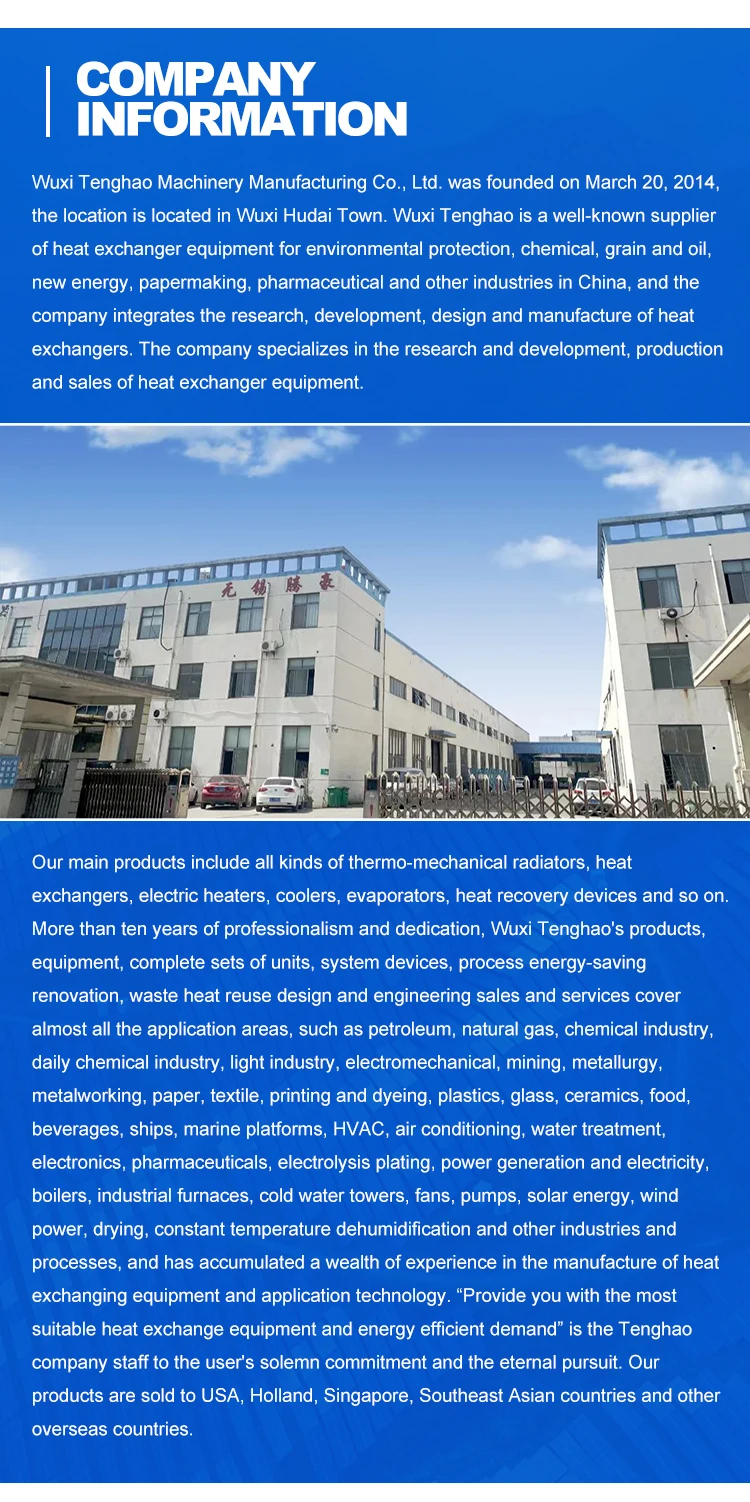

Company Profile

Product packaging

Contact information

FAQ

Q:Worry about your money? A: Trade Assurance can protect your money. (more information, pls contact me) Q: Are you trading company or manufacturer ? A: We are factory.specilizing in heat exchanger for over 10 years. Q:Are your products customized? A:Yes,the products in the website are only the common type or the previous types from other customers,we can supply the newproducts according to your requirements or drawings. Q: How long is your delivery time? A: Generally it is 10-15 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity. Q: WHY CHOOSE US? A:We have strong technical force, with more than 10 years of experience in research and development of heat exchangers,We are committed to providing our customers with the most suitable heat transfer equipment and efficient energy saving needs.