Products Description

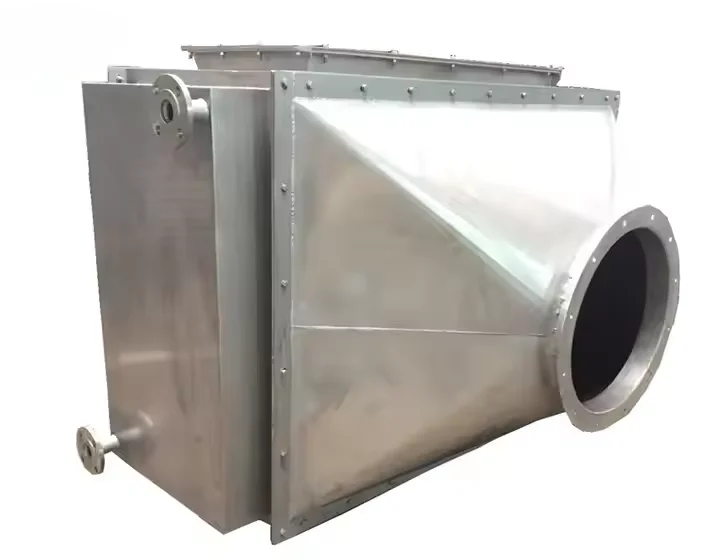

Flue gas heat exchanger

This industrial stainless steel heat exchanger is made of high-quality stainless steel and is specially designed for industrial fluid heat exchange scenarios. With its advanced heat exchange structure and reliable manufacturing process, it can precisely transfer thermal energy between hot and cold fluids, widely meeting the energy-saving and temperature control requirements of various industries, helping enterprises improve energy utilization efficiency and stabilize production processes.

Excellent material, durable and reliable

The main body is made of high-quality stainless steel (such as 304/316L, etc., customizable options available), featuring strong corrosion resistance and being immune to the erosion of acidic and alkaline substances, high-temperature smoke and other media in industrial environments. It has excellent thermal conductivity, accelerating the efficiency of heat exchange, and also possesses outstanding mechanical strength. It is unlikely to deform or be damaged during long-term operation, and its service life far exceeds that of ordinary material equipment.

High-efficiency heat exchange, significant energy saving

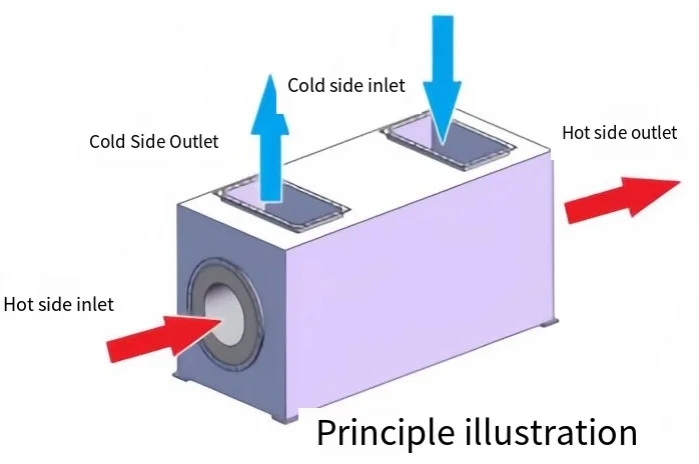

The innovatively designed heat exchange core structure (such as finned tubes, tube bundles, etc., optimized as needed) significantly increases the heat exchange area and enhances the heat transfer between hot and cold fluids. It can efficiently recover residual heat from industrial waste gas, wastewater, etc., or precisely control the temperature of process fluids, helping enterprises reduce energy consumption, lower heating/cooling costs, and achieve the goal of energy conservation and emission reduction.

Flexible customization, suitable for a wide range of applications

Supports full-process customized services: According to different industries (such as chemical, power, food, etc.) and different process requirements, customize parameters such as shell size, inlet and outlet specifications, heat exchange power, etc. Whether it is the waste heat recovery of large industrial boilers or the temperature control of food processing lines, it can be precisely adapted to meet diverse scenarios.

Video presentation

Manufacturing Technique

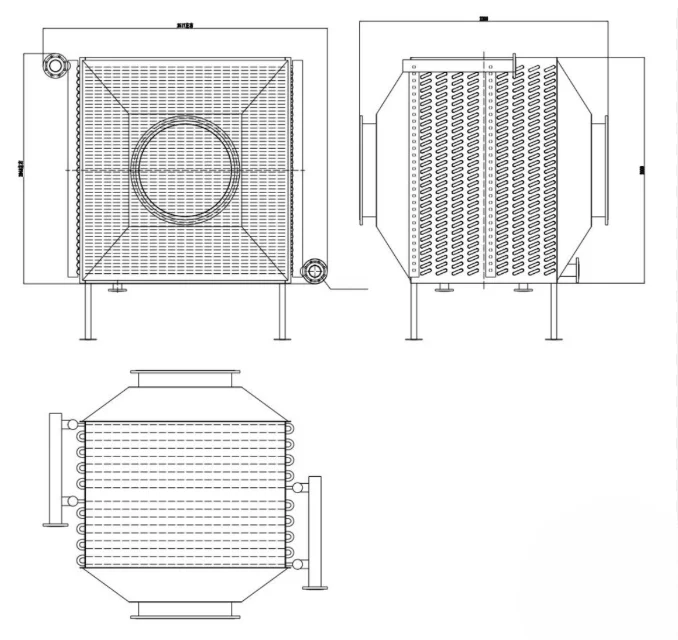

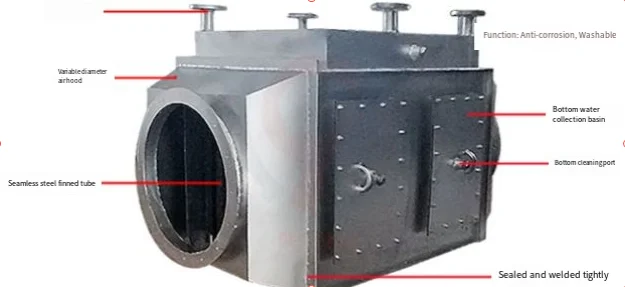

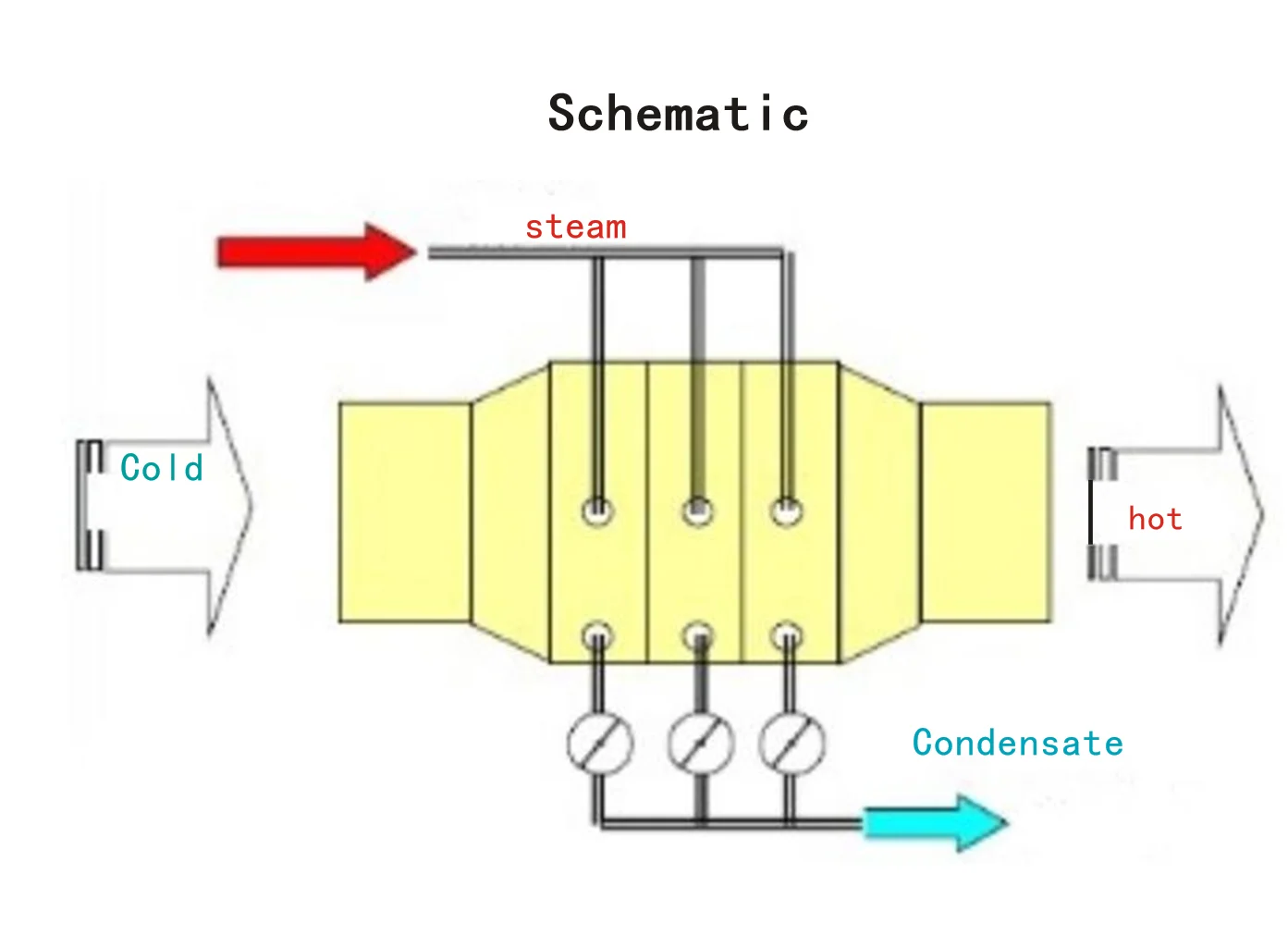

Main structure

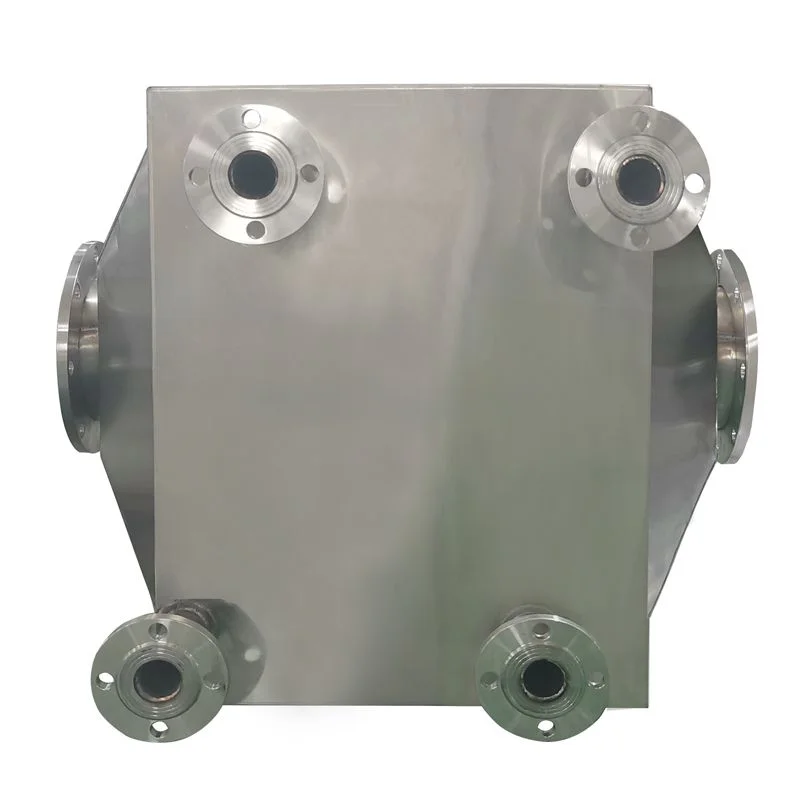

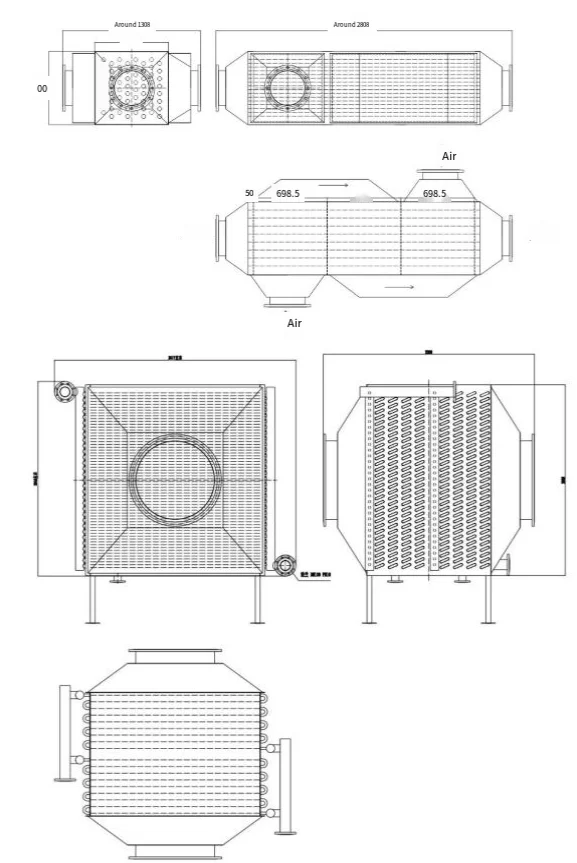

(1) Main Structure Heat exchange core: The core heat exchange component, through optimizing the layout of fins / tube bundles, maximizes heat exchange efficiency. Different structural forms (such as shell-and-tube type and plate type) can be selected according to the working conditions (such as different fluid pressure and flow rate). Stainless steel shell: Provides a sealed heat exchange space, guides the fluid to flow along the preset path, and has pressure-bearing and corrosion-resistant properties, suitable for complex industrial conditions; the inlet and outlet flanges are standardized, facilitating quick connection with the pipeline system. Auxiliary components: Optional temperature sensors, pressure monitoring ports, and blow-off valves can be equipped to achieve real-time monitoring of operating parameters and facilitate convenient equipment maintenance. (2) Installation and Maintenance Installation is convenient: Supports horizontal / vertical installation, suitable for different site layouts; the connection of inlet and outlet pipes is simple, and in combination with standardized flanges, it can be quickly integrated into the existing system, reducing the construction period. Maintenance is worry-free: Stainless steel material is not prone to scaling or corrosion. Daily maintenance only requires regular cleaning of the inlet and outlet filters (as needed) and inspection of the seals; the equipment is reserved with maintenance ports, facilitating core body cleaning and fault diagnosis, reducing operation and maintenance costs.

Technical Specifications (Typical Configuration, Customizable)

Parameter item Typical value Explanation Material 304 stainless steel / 316L stainless steel Corrosion resistance grade is optional Design pressure 0.6 - 2.5 MPa (standard) Customizable for high-pressure conditions Design temperature -20℃ - 400℃ (standard) Suitable for different medium temperature requirements Heat exchange area 5 - 500 m² (customized as needed) Matching heat exchange scale Inlet and outlet pipe diameter DN50 - DN300 (flange connection) Compatible with pipeline system Energy efficiency ratio (COP) 2.5 - 4.0 (standard conditions) Reflects heat exchange efficiency; the higher, the more energy-efficient

Recommend Products

Company Profile

Product packaging

Contact information

FAQ

Q:Worry about your money? A: Trade Assurance can protect your money. (more information, pls contact me) Q: Are you trading company or manufacturer ? A: We are factory.specilizing in heat exchanger for over 10 years. Q:Are your products customized? A:Yes,the products in the website are only the common type or the previous types from other customers,we can supply the newproducts according to your requirements or drawings. Q: How long is your delivery time? A: Generally it is 10-15 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity. Q: WHY CHOOSE US? A:We have strong technical force, with more than 10 years of experience in research and development of heat exchangers,We are committed to providing our customers with the most suitable heat transfer equipment and efficient energy saving needs.