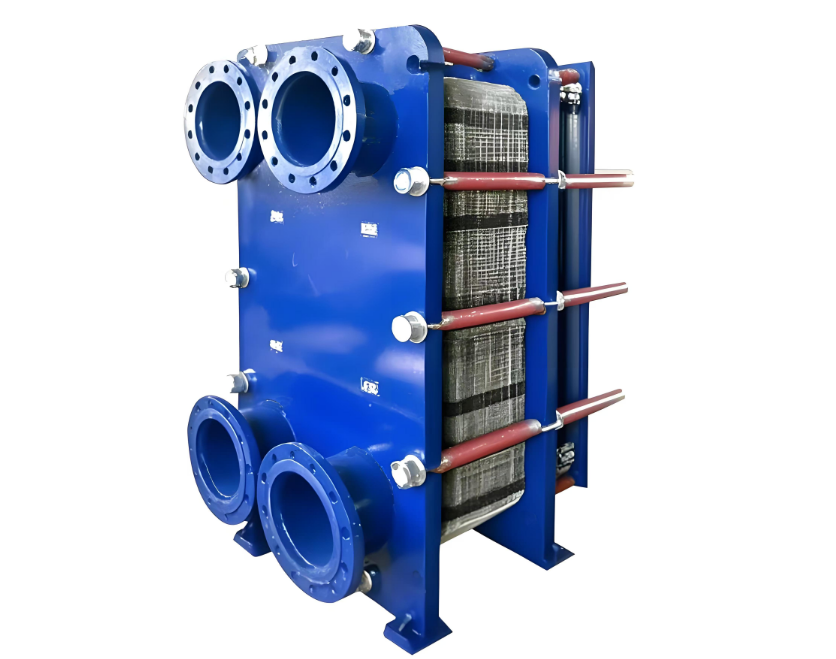

In the world of modern cooling and heating, the quest for greater efficiency and smaller footprints has led to significant innovations. A prime example of this evolution is the compact blue heat exchanger, a critical component that is redefining performance in various systems. As industries demand more compact refrigeration solutions without compromising on power, understanding the technology behind these advanced units becomes essential for optimizing energy consumption and operational costs. These devices are meticulously engineered to deliver robust performance in both demanding industrial and commercial settings, setting a new standard for thermal management technology.

The Innovation Behind Blue Heat Exchanger Technology

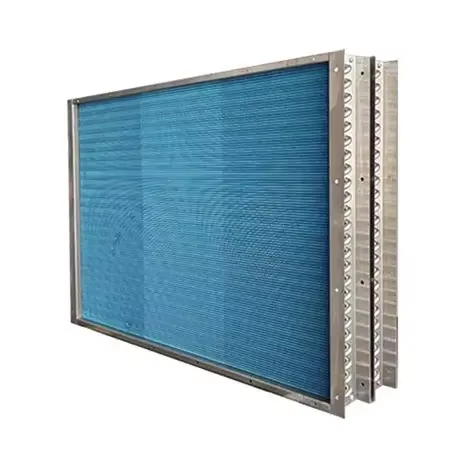

What sets this technology apart are the specific advancements in its design and materials. The distinctive blue coating is not merely for aesthetics; it is a specially formulated, corrosion-resistant layer that offers superior protection against environmental wear and tear. This is crucial for ensuring longevity, especially in the rigorous conditions of continuous operation. As one of the most vital refrigeration unit components, a heat exchanger's durability directly impacts the entire system's reliability and lifespan. The core of blue heat exchanger technology is focused on maintaining clean and efficient heat transfer surfaces over time, preventing the performance degradation often seen in conventional, uncoated units. This advanced engineering guarantees consistent heat exchange, which is the backbone of any high-performing HVAC or refrigeration system.

Driving Efficiency and Optimizing Systems

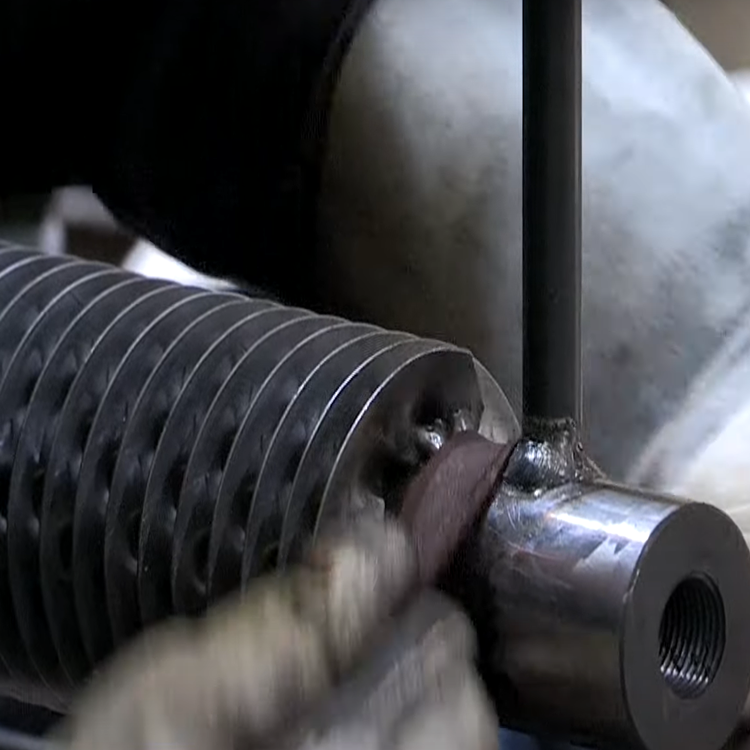

One of the most compelling benefits of adopting this advanced hardware is the significant boost in energy efficiency. These units are designed to be premier energy-efficient heat exchangers, maximizing thermal transfer with minimal energy input. The intricate design of the internal pipes and fins creates a larger effective surface area within a smaller physical volume, which facilitates rapid and uniform heat distribution. This process is fundamental to refrigeration system optimization, as it allows compressors and other system components to operate under less strain. This, in turn, reduces electricity consumption and lowers ongoing operational expenses. For any business, this translates into tangible savings and a smaller carbon footprint, aligning perfectly with modern goals for eco-responsible and sustainable operations. The precise temperature control offered is another hallmark, ensuring that systems maintain desired conditions without wasteful energy spikes.

Versatility and Integration as a Heat Exchanger for Refrigeration

The robust and compact design makes the blue heat exchanger incredibly versatile. It serves as an ideal heat exchanger for refrigeration, fitting seamlessly into a wide array of applications, from commercial freezers and walk-in coolers to large-scale industrial HVAC installations. Its small size is a major advantage in scenarios where space is at a premium, allowing for powerful cooling performance without requiring a large physical footprint. This adaptability makes it a perfect choice for both upgrading existing, outdated systems and designing new, efficient ones from the ground up. Furthermore, the ease of installation and minimal maintenance requirements enhance its appeal, reducing potential downtime and streamlining the integration process for technicians. Whether for a new build or a strategic retrofit, these units provide a reliable, high-performance solution.