The Challenge of Modern Industrial Thermal Management

In today's competitive industrial landscape, optimizing every aspect of production is paramount. A significant and often underestimated challenge lies in thermal management. Inefficient control over process temperatures can lead to increased energy consumption, reduced product quality, and even equipment failure. The core of this issue revolves around effective fluid heat transfer, a process essential for everything from chemical processing to food and beverage production. Many facilities struggle with outdated or bulky equipment that fails to meet the demands for higher efficiency and a smaller operational footprint, creating a pressing need for advanced thermal exchange systems that can solve these complex problems.

A Superior Solution: The High-Efficiency Industrial Heat Exchanger

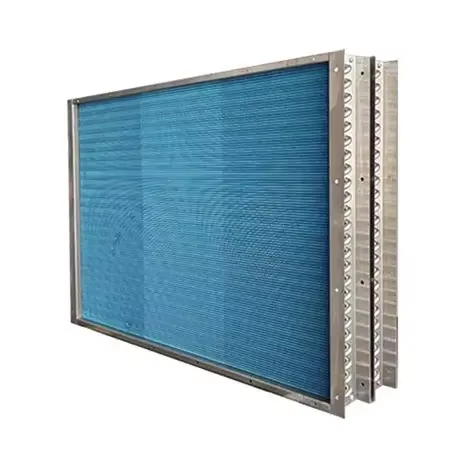

Fortunately, technological advancements provide a powerful solution: the modern industrial heat exchanger. These units are specifically engineered to address the shortcomings of older systems. Among the most impactful innovations is the plate heat exchanger, a compact yet incredibly powerful device. Unlike traditional shell-and-tube models, these high efficiency heat exchangers utilize a series of corrugated plates to create a large surface area in a small volume. This design maximizes thermal exchange between two fluids, drastically improving energy efficiency and providing precise temperature control, which is critical for sensitive industrial applications.

Innovations in Heat Exchanger Design

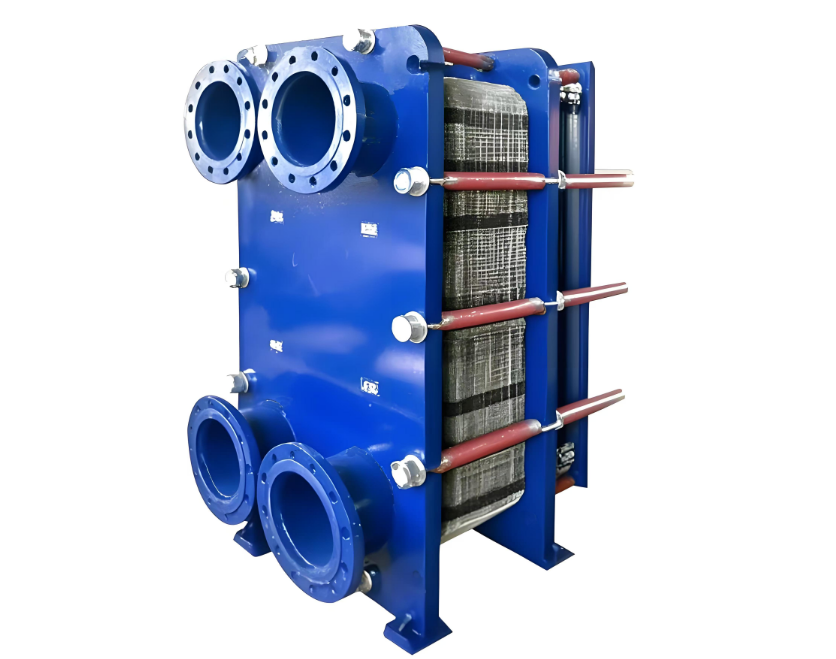

Our latest model exemplifies the peak of modern heat exchanger design. It is engineered from the ground up to solve common integration and reliability problems. At the top and bottom, large-diameter flanged connections, built to international standards, ensure seamless and leak-proof integration into existing piping systems, even under high-pressure conditions. The unit's structural integrity is guaranteed by a striking blue high-strength frame, designed to withstand intense operational stress. This robust construction ensures longevity and reliability, protecting your investment and preventing costly downtime. This thoughtful engineering makes our industrial plate heat exchangers a benchmark for performance and durability.

Maximizing Uptime and Performance with Smart Engineering

The true genius of this plate heat exchanger lies in its maintenance-friendly features. The plate pack is compressed by distinctive red tension rods, which are crucial for maintaining the precise alignment and tightness required for optimal performance. Critically, this tensioning mechanism is fully adjustable, which dramatically simplifies maintenance. Technicians can easily access, clean, or replace individual plates without extensive disassembly, minimizing operational interruptions. This focus on serviceability ensures that the equipment maintains its peak efficiency over its entire lifespan, directly contributing to lower operating costs and consistent production output. This advanced approach to the system's mechanics ensures that performance and practicality go hand in hand.

The Future of Efficient Industrial Processes

Adopting advanced thermal management technology is no longer an option but a necessity for forward-thinking industries. By solving the core problems of energy waste, inefficient space utilization, and difficult maintenance, our state-of-the-art industrial heat exchanger offers a clear path toward enhanced productivity and sustainability. This equipment is more than just a component; it's a comprehensive solution designed to boost your bottom line. By integrating such a high-performance fluid heat transfer system, you are investing in reliability, efficiency, and the future success of your operations.