In today's industrial landscape, optimizing energy use while maximizing operational output is a paramount concern. A High Efficiency Heat Exchanger stands at the forefront of this movement, serving as a critical component in countless thermal management systems. These devices are essential for transferring heat between two or more fluids, enabling processes that range from simple heating and cooling to complex energy recovery. The drive for greater sustainability and lower operating costs has pushed the innovation of these systems, making their design and material composition more important than ever for achieving peak performance in demanding environments.

The Core of Advanced Thermal Transfer

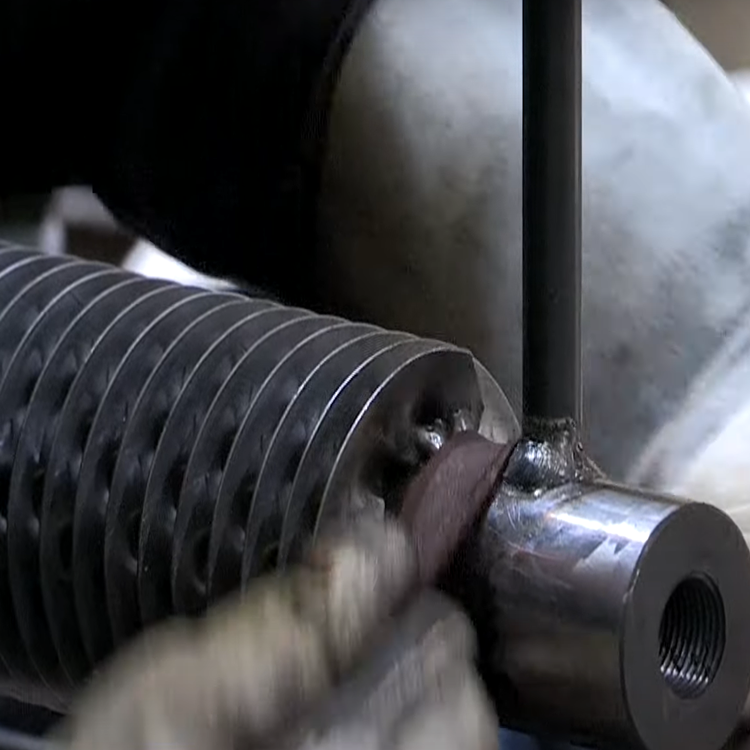

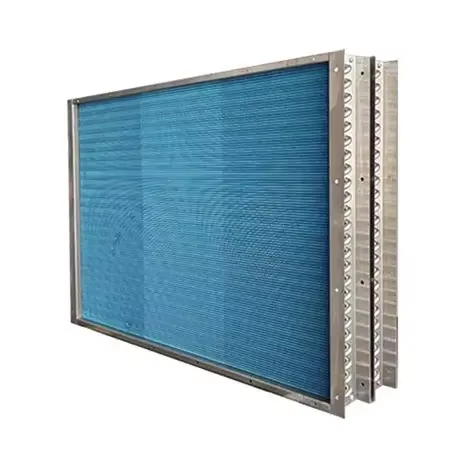

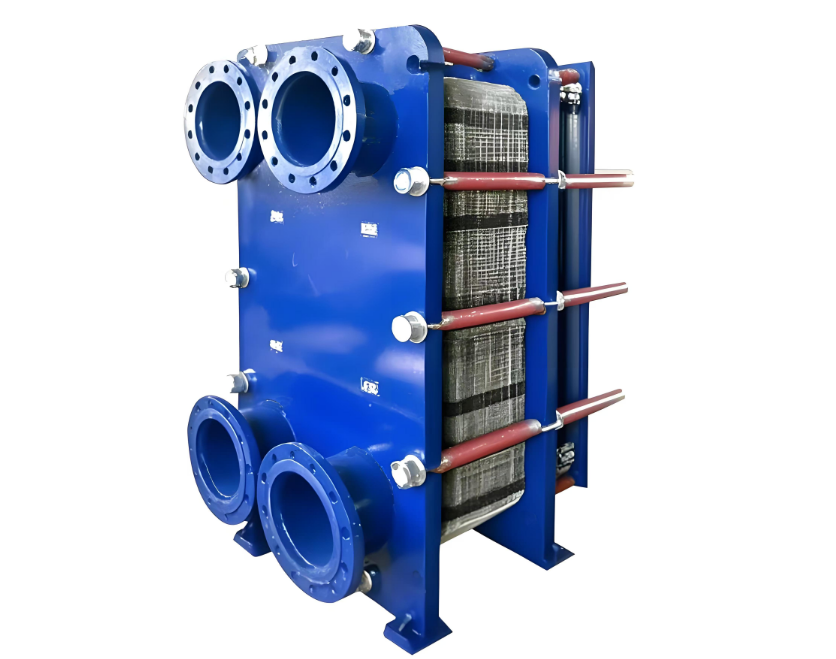

The effectiveness of any heat exchange system originates from its central component: the Heat Exchanger Core. This intricate assembly is meticulously engineered to maximize the surface area over which thermal transfer can occur. The design of the core, including the spacing of its fins and the layout of its tubing, directly influences the unit's overall efficiency and pressure drop. A well-designed core facilitates a smooth flow of air or fluid while ensuring the highest possible rate of heat transfer, forming the foundational element upon which the entire system's performance is built. This is where cutting-edge engineering meets practical application, creating a powerhouse of thermal regulation.

Synergistic Materials: Copper and Aluminum

The choice of materials is fundamental to the performance of a heat exchanger. A Copper Tube Heat Exchanger is prized for its superior thermal conductivity, allowing heat to move rapidly and efficiently through the system. Copper's inherent properties make it an ideal medium for the primary fluid pathways. Complementing this is the Aluminum Fin Heat Exchanger design. Aluminum is lightweight, durable, and offers excellent heat dissipation properties, making it perfect for the fins that draw heat away from the tubes and into the passing air stream. The combination of these two materials results in a Copper Aluminum Heat Exchanger, a hybrid solution that leverages the best qualities of each metal to create a highly effective, durable, and cost-efficient system for thermal management.

Achieving Peak Performance and Energy Efficiency

A truly modern system is defined by its ability to perform its function with minimal waste, which is why the development of an Energy Efficient Heat Exchanger is a key focus for manufacturers. By optimizing fluid dynamics and maximizing thermal transfer, these units reduce the energy required to heat or cool a medium, leading to significant reductions in operational costs and environmental impact. The Thermal Performance Heat Exchanger is evaluated on its capacity to achieve desired temperature changes with minimal energy input. Innovations such as large-intake designs and adjustable louvers enhance airflow control, further boosting performance. This commitment to efficiency is often validated by international certifications like CE and ISO 9001, assuring users of the system's quality, safety, and sustainable operation.

Built for Industrial Demands

The modern Industrial Heat Exchanger is engineered to withstand the rigors of heavy-duty use in environments like factories, warehouses, and large-scale commercial facilities. These settings require equipment that is not only powerful but also exceptionally reliable and durable. An industrial-grade unit must handle continuous operation, potential exposure to corrosive elements, and high-volume throughput without faltering. The robust construction and use of high-quality materials ensure a long service life and minimal maintenance, making the Industrial Heat Exchanger an indispensable asset for maintaining optimal conditions and process integrity in any large-scale operation.