Understanding the Core of High Efficiency Plate Heat Exchangers

In the world of industrial processing, HVAC systems, and refrigeration, the quest for greater efficiency is constant. A High Efficiency Plate Heat Exchanger stands at the forefront of this movement, offering a superior method for transferring heat between two fluids. Unlike traditional shell-and-tube exchangers, these modern units utilize a series of specially designed plates to maximize thermal exchange in a much smaller footprint. The fundamental goal is to achieve Energy Efficient Heat Transfer, reducing operational costs and minimizing environmental impact. This guide will walk you through the key aspects of these systems, explaining how their design, structure, and performance come together to provide an exceptional solution for thermal management.

Deconstructing the Plate Heat Exchanger Design

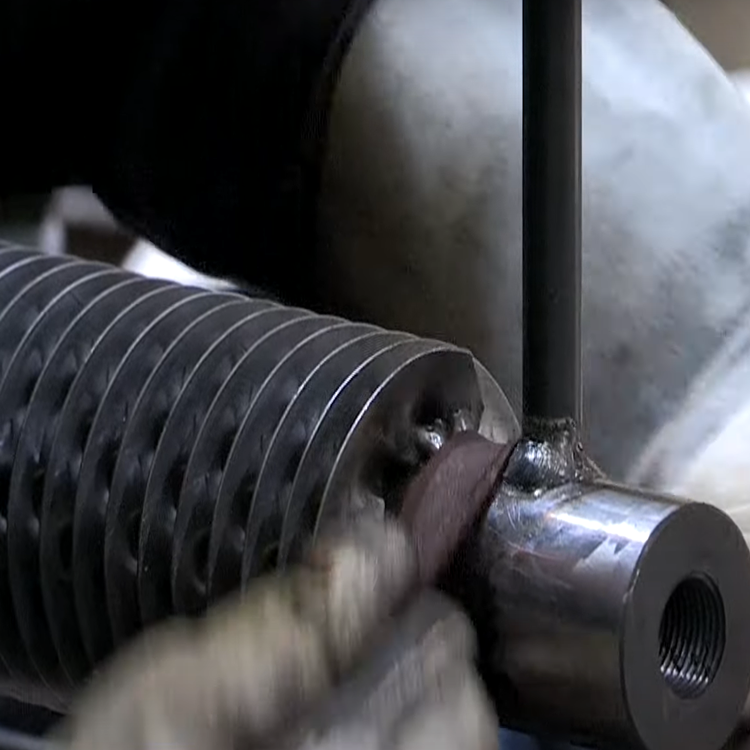

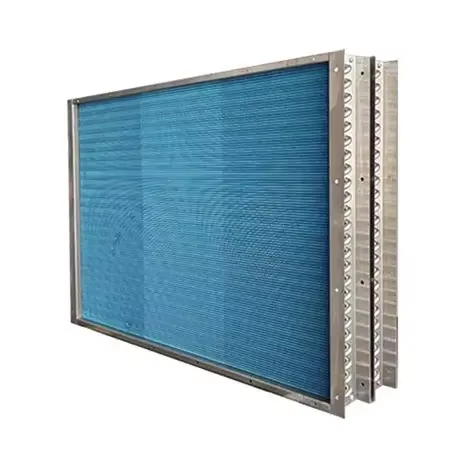

The secret to the effectiveness of these units lies in the sophisticated Plate Heat Exchanger Design. At its heart is a stack of thin, corrugated metal plates, typically made from stainless steel or other durable alloys. These plates are pressed with intricate patterns, such as a honeycomb or chevron design, which serve two critical purposes. First, the pattern significantly increases the surface area available for heat transfer compared to a flat plate of the same dimensions. Second, it creates turbulence in the fluid flow. This turbulent flow prevents a static boundary layer from forming on the plate surface, ensuring that more of the fluid comes into contact with the heat transfer surface, which dramatically boosts Heat Exchanger Performance. The plates are arranged so that the hot and cold fluids flow in alternating channels, allowing for a highly efficient counter-current flow that maximizes the temperature difference and, consequently, the rate of heat transfer.

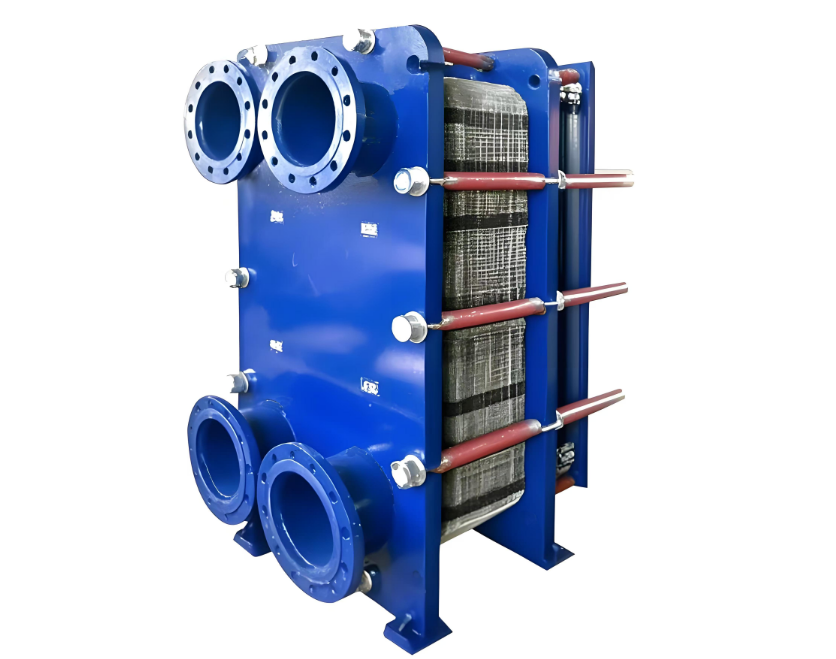

Why a Robust Frame Structure Matters

While the internal plates do the work, the external structure ensures the unit's longevity and reliability. A Robust Frame Structure Heat Exchanger is essential for maintaining the integrity of the plate pack, especially under high pressure and demanding industrial conditions. This frame typically consists of thick, fixed and movable pressure plates held together by heavy-duty carrying bars and tightening bolts. This bolted construction not only provides the clamping force needed to seal the plate pack and prevent leaks but also allows for easy disassembly. The ability to open the unit is a significant advantage, simplifying maintenance, cleaning, and even capacity expansion. For facilities looking for Industrial Heat Exchanger Solutions, a Durable Plate Heat Exchanger with a strong frame is a non-negotiable feature, guaranteeing a long service life and consistent operation.

Achieving Peak Thermal Efficiency in Your Operations

The ultimate goal of any heat exchange system is maximum efficiency, and this is where a Thermal Efficiency Plate Heat Exchanger truly shines. The combination of the high-surface-area plates, turbulence-inducing patterns, and true counter-current flow results in extremely high heat transfer coefficients. This means the exchanger can achieve the required temperature change using a much smaller surface area than other types of exchangers. This efficiency translates directly into tangible benefits: lower energy consumption for pumping fluids, less space required for installation, and faster response to changes in operating conditions. Choosing the right unit ensures that your processes, whether for cooling, heating, or energy recovery, operate at their peak potential, making it a cornerstone of modern, sustainable industrial operations.