Solving the Thermal Challenge in Modern Industry

In countless industrial settings, from chemical processing to power generation, managing thermal energy is a critical operational challenge. Uncontrolled heat can lead to equipment damage, decreased productivity, and significant energy waste. An effective solution to this widespread problem is the proper implementation of a high-performance Industrial Heat Exchanger, a device engineered to efficiently transfer thermal energy from one medium to another. Choosing the right exchanger and integrating it into a well-designed system is the first step toward achieving operational excellence and sustainability.

The Heart of Efficiency: Understanding Heat Transfer Technology

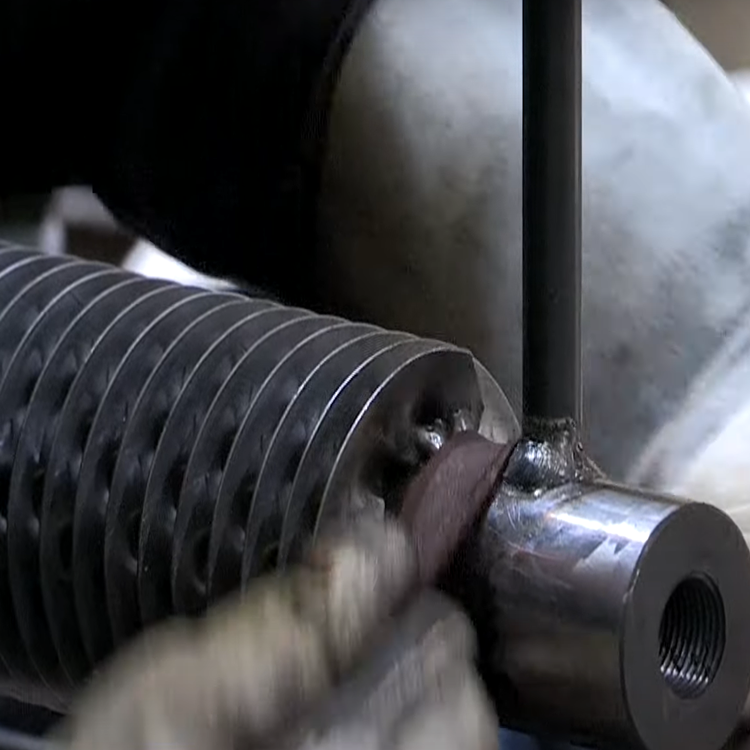

At its core, a heat exchanger operates on the principles of advanced Heat Transfer Technology. The goal is to maximize the rate of thermal exchange while maintaining the integrity and separation of the fluids involved. The effectiveness of this process directly impacts Heat Exchanger Efficiency. Designs that feature premium-grade materials, such as high-performance steel, and innovative engineering to reduce turbulence and optimize flow, are paramount. When the underlying Heat Transfer Technology is compromised by poor materials or flawed design, the result is subpar performance, increased energy consumption, and a higher risk of system failure.

Navigating the Options: Types of Heat Exchangers

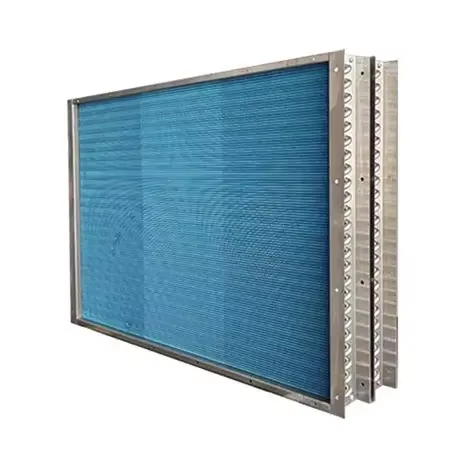

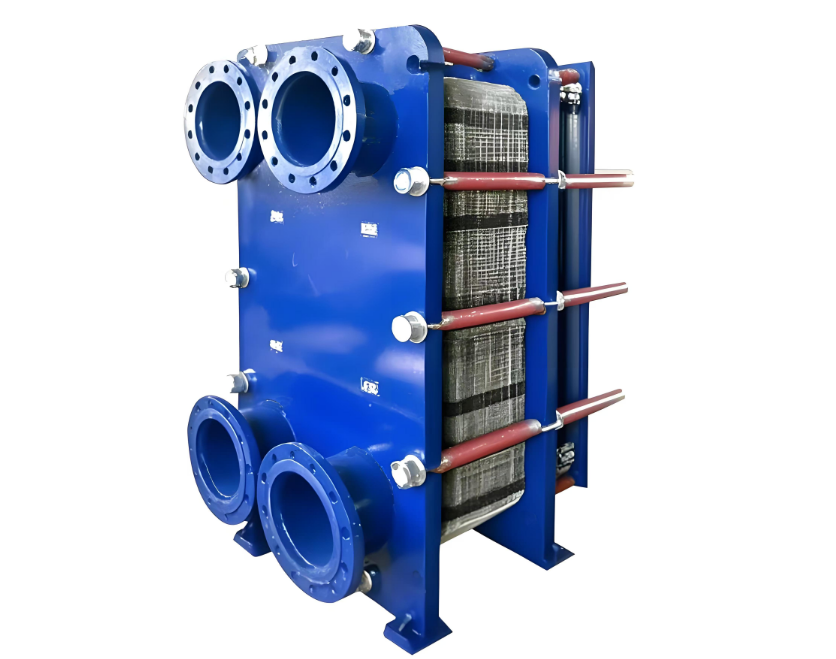

Not all heat exchangers are created equal, and the market offers various designs to suit specific needs. The different Types of Heat Exchangers, such as shell-and-tube or spiral models, each have their own advantages. Among the most popular and versatile are Plate Heat Exchangers, which use a series of stacked plates to create a large surface area for heat transfer in a compact footprint. The selection process is critical; the choice depends entirely on the specific Heat Exchanger Applications. Whether for HVAC, petrochemical transfer, or renewable energy plants, using the wrong type of exchanger for the job can lead to inefficiency, fouling, and costly downtime. A careful analysis of the operational parameters—including fluid types, temperatures, and pressures—is essential to identify the right solution from the many Types of Heat Exchangers available.

From Concept to Reality: The Importance of Heat Exchanger Design

A successful thermal management system goes beyond simply selecting a model; it requires meticulous Heat Exchanger Design. This phase considers everything from the physical footprint to its integration with the surrounding industrial piping system. An optimal Heat Exchanger Design focuses on durability, serviceability, and performance. This includes utilizing materials resistant to corrosion and crafting joints and bends that promote smooth, efficient flow. A well-engineered system is not just functional but also scalable and easy to maintain, ensuring it delivers reliable performance for years to come. This focus on precision Heat Exchanger Design is what separates standard components from a truly integrated, high-efficiency solution.

Protecting Your Investment: Heat Exchanger Maintenance and Efficiency

Once installed, an industrial heat exchanger requires ongoing attention to maintain its performance. Regular Heat Exchanger Maintenance is not an option but a necessity for long-term viability. Over time, issues like fouling, scaling, and corrosion can drastically reduce Heat Exchanger Efficiency, forcing pumps to work harder and increasing energy costs. A proactive maintenance plan, including periodic inspections and cleaning, prevents these problems from escalating into unexpected shutdowns. A system built with robust engineering and high-quality materials simplifies the Heat Exchanger Maintenance process, but it does not eliminate it. Protecting your investment and ensuring peak Heat Exchanger Efficiency depends on a consistent commitment to upkeep.