Understanding Steam Heat Exchangers

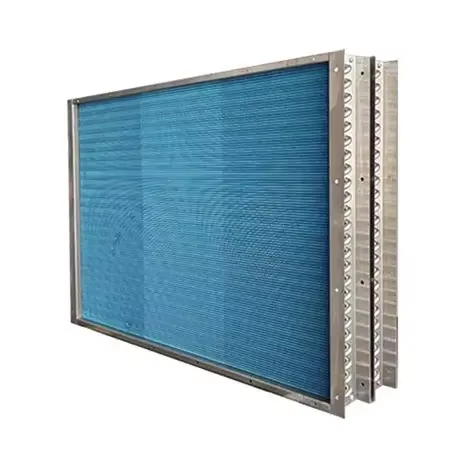

Steam heat exchangers are a vital component in various industrial applications, serving as the bridge between primary energy sources and their ultimate uses. These devices efficiently facilitate thermal energy transfer, a crucial function in maintaining operational effectiveness in industries ranging from manufacturing to HVAC systems. The cutting-edge technology found in modern steam heat exchangers, such as finned heat exchangers, exemplifies efficiency in heat dissipation — a requirement in the high-demand industrial settings where these systems are typically employed.

Optimizing Heat Exchanger Systems

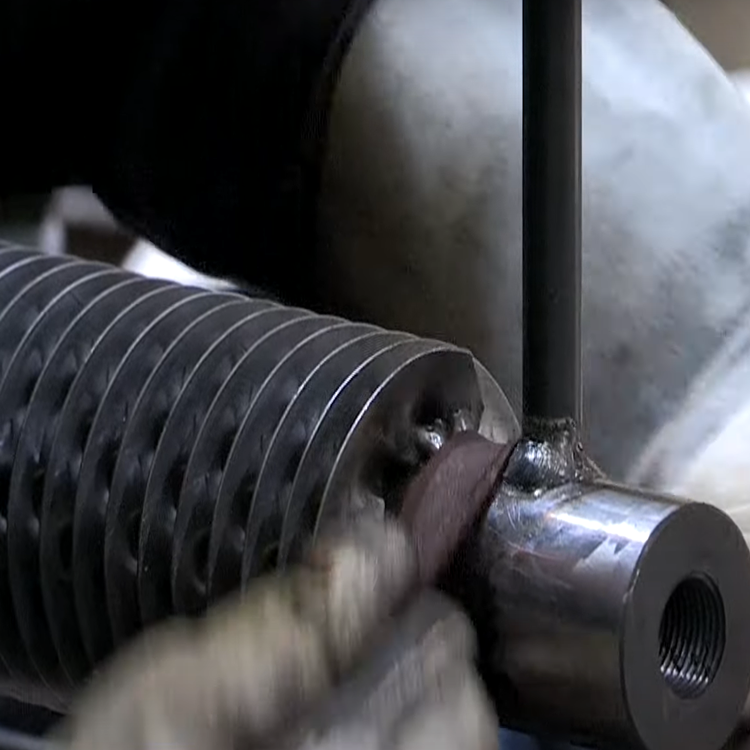

The design of heat exchanger systems plays a pivotal role in the optimization of steam systems. Modern heat exchangers are engineered with precision to ensure optimal thermal energy transfer, thereby enhancing the overall efficiency of a facility's operations. The distinctive finned structures in these exchangers significantly improve heat exchange rates by increasing the surface area for interaction, a critical approach for maximizing performance without expanding the device's overall footprint. Industrial heat exchangers today are expected to handle high pressures and temperatures, demanding designs that are both robust and flexible.

The Importance of Industrial Heat Exchanger Design

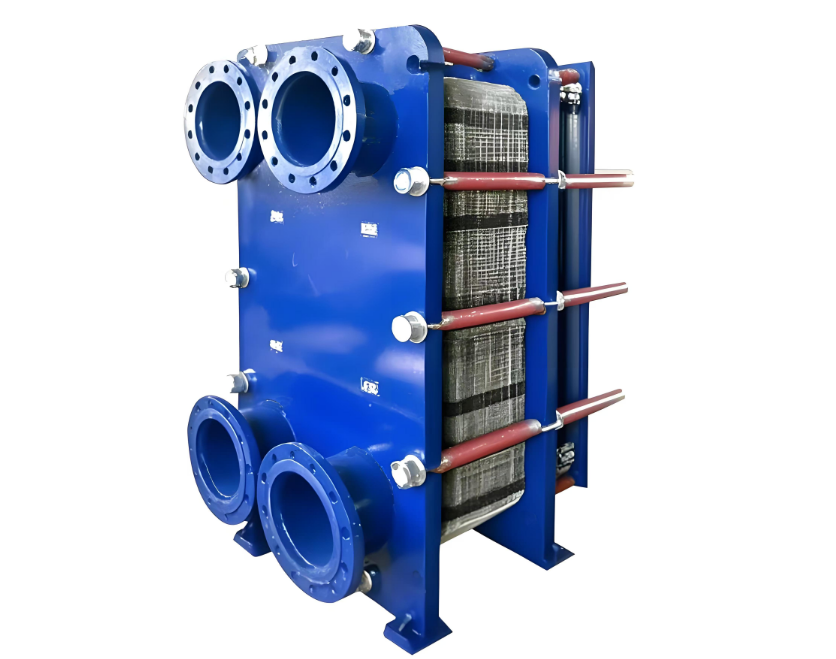

The design and functionality of industrial heat exchangers are constantly evolving to meet growing industrial demands. A well-designed heat exchanger can drastically improve a facility's energy efficiency by streamlining the process of thermal energy transfer. By integrating features like easy maintenance and scalability, today's heat exchangers allow for adaptability in diverse industrial scenarios. The modular design ensures these systems can be customized to suit specific operational constraints, a necessity for any forward-thinking industrial setup.

Advancements in Steam System Optimization

Effective steam system optimization hinges on the development and implementation of advanced heat exchanger designs. The benefits of incorporating leading-edge technology, like that found in the latest finned heat exchangers, cannot be overstated. These innovations contribute significantly to energy conservation efforts, reduce operational costs, and minimize environmental footprints. The improvements in heat exchanger design have augmented the reliability and efficiency of steam systems, cementing their role as indispensable components in modern industrial processes.

Conclusion

In sum, steam heat exchangers are an essential element in the landscape of industrial energy management. The evolution of heat exchanger systems, marked by innovations in steam system optimization and thermal energy transfer, continues to shape the capabilities and efficiencies of modern industrial operations. As industries seek ways to enhance performance while maintaining cost-effectiveness, investing in advanced, well-designed heat exchangers proves to be a wise strategic move. The prowess of these systems in transforming energy management highlights the importance of ongoing innovation within this sector.