The Cornerstone of Modern Thermal Efficiency

In today's energy-conscious world, the demand for systems that perform optimally while minimizing waste has never been greater. At the heart of this movement lies the high efficiency heat exchanger, a critical component in countless industrial and commercial applications. These meticulously engineered devices are the unsung heroes of thermal management, enabling processes that are both powerful and sustainable. As advancements in heat transfer technology continue to evolve, they unlock new levels of performance, driving industries forward and redefining what is possible in energy conservation and operational excellence.

Anatomy of an Advanced Heat Exchanger

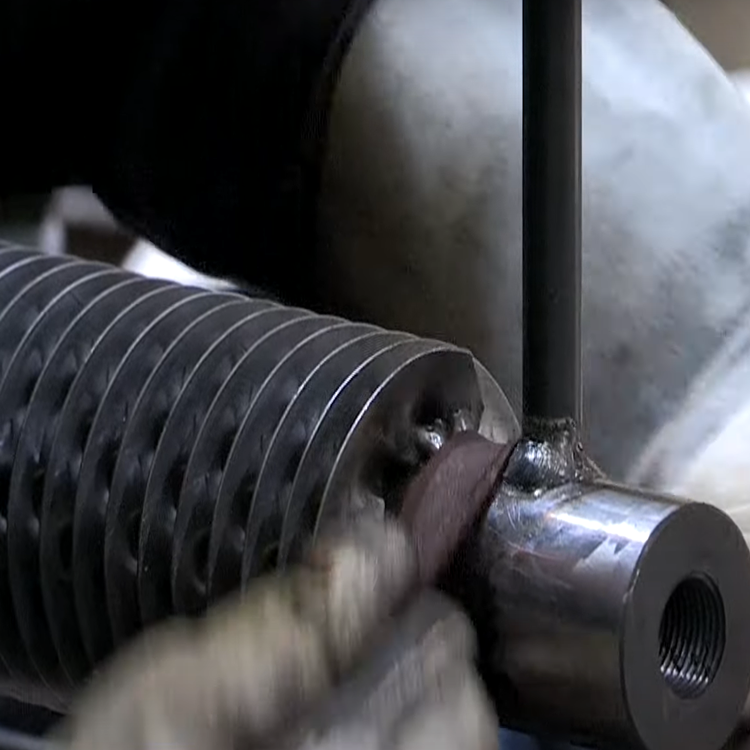

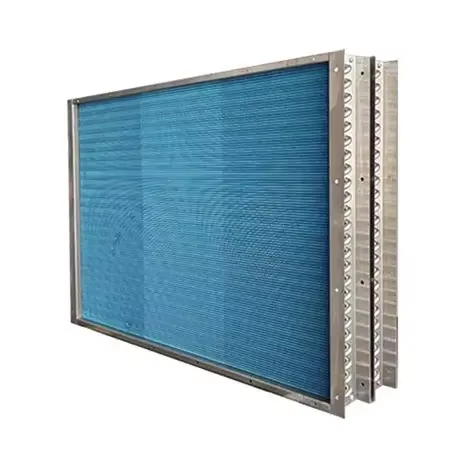

To understand what makes these devices so effective, we must look at the heat exchanger core. This is where the magic of thermal transfer happens. A prevalent and highly effective design is the copper tube aluminum fin heat exchanger. This combination leverages the unique properties of each material to create a synergistic effect. The core of a copper tube heat exchanger offers superior thermal conductivity, allowing heat to move rapidly from the fluid inside the tubes to the tube walls. Surrounding these tubes, the aluminum fin heat exchanger component provides a vast surface area. These lightweight fins dissipate the heat into the surrounding air with remarkable speed, creating a robust and efficient system for thermal regulation.

Powering High-Performance Industrial Systems

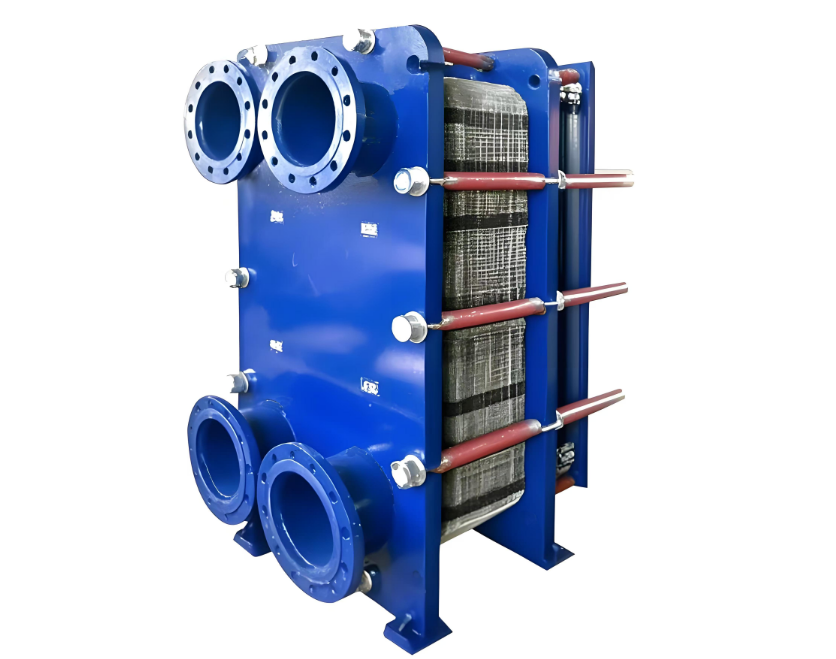

From large-scale manufacturing plants to sophisticated data centers, the application of this technology is widespread. High efficiency cooling systems rely on these components to maintain precise temperature control, protecting sensitive equipment and ensuring process stability. In demanding environments, industrial heat exchangers must be both powerful and incredibly reliable. They are integral to HVAC systems, power generation, chemical processing, and refrigeration, where any failure can lead to significant downtime and cost. The robust design of a modern heat exchanger core ensures it can withstand the pressures and temperatures of continuous operation, providing dependable performance day in and day out.

The Science of Superior Heat Transfer

Advanced heat transfer technology is built on fundamental principles of thermodynamics, but its modern application involves sophisticated engineering. In a copper tube aluminum fin heat exchanger, the design is optimized down to the smallest detail. The spacing of the fins, the pattern of the tubes, and the turbulence created within the fluid pathways are all calculated to maximize the rate of heat exchange. This meticulous engineering ensures that the maximum amount of thermal energy is transferred, which is the defining characteristic of a high efficiency heat exchanger. This focus on scientific optimization results in systems that require less energy to operate, directly translating to lower operational costs and a smaller environmental footprint.

Choosing the Future of Thermal Management

As industries continue to seek out more sustainable and cost-effective solutions, the importance of high-quality industrial heat exchangers will only grow. Investing in advanced designs, such as a well-engineered copper tube heat exchanger with aluminum fins, is an investment in long-term efficiency and reliability. These components are more than just parts; they are foundational elements of a smarter, greener industrial landscape. By embracing this technology, companies can not only enhance their own operations but also contribute to a more sustainable global future, proving that peak performance and environmental responsibility can go hand in hand.