The Evolution of Thermal Management

In today's rapidly advancing industrial and commercial sectors, the demand for effective thermal management has never been greater. Achieving optimal temperature control is not just about comfort; it's about operational efficiency, energy conservation, and sustainability. At the heart of this challenge lies the need for innovative components that can deliver powerful performance in a minimal footprint. This is where the compact finned tube heat exchanger emerges as a pivotal technology, offering one of the most effective compact heat exchange solutions available on the market. These devices are fundamental to modern systems, enabling precise and reliable regulation of temperature across a vast array of applications.

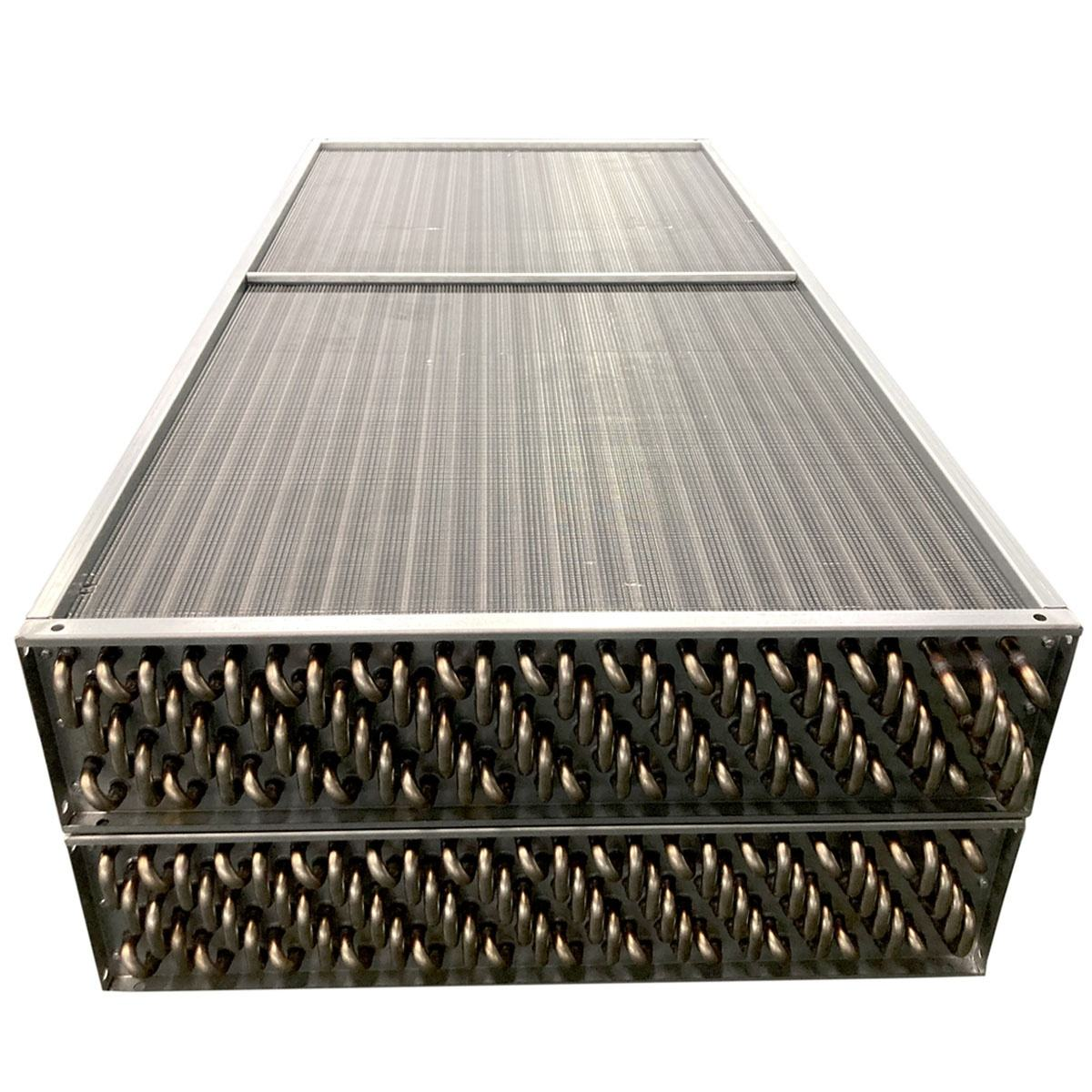

Unlocking Efficiency with Finned Tube Design

The core principle behind the exceptional performance of these units lies in the ingenious finned tube design benefits. A standard tube has a limited surface area for heat to transfer to or from the surrounding air. By attaching a series of thin plates, or fins, along the length of the tube, the effective surface area is dramatically increased. This simple yet profound enhancement allows for a much higher rate of thermal transfer in the same amount of space. This is the essence of superior heat transfer technology; it maximizes the interaction between the fluid inside the tubes and the air outside. As a result, systems equipped with these components become incredibly efficient heat exchangers, capable of achieving desired temperature changes more quickly and with significantly less energy consumption.

Versatile Industrial and Commercial Applications

The adaptability of the compact finned tube heat exchanger makes it a cornerstone of numerous industries. There is a wide range of heat exchanger industrial applications, from large-scale manufacturing processes to sophisticated climate control systems. In the world of HVAC, these units are indispensable for both air conditioning and heating, ensuring comfortable environments in residential homes, office buildings, and commercial centers. In refrigeration, they are critical for the condensation and evaporation cycles that keep food and other perishables preserved. The compact nature of these devices is particularly advantageous in applications where space is at a premium, allowing engineers to design powerful systems without requiring a large physical footprint.

Advanced Engineering for Modern Demands

Modern advancements in materials science and manufacturing have further elevated the capabilities of these thermal management devices. Today's units are built with durability in mind, crafted from high-quality materials that resist corrosion and withstand temperature fluctuations. This robust construction ensures long-term reliability and reduces the need for frequent maintenance. Furthermore, many designs are now modular, which simplifies the installation process and makes servicing easier, minimizing operational downtime. This focus on engineering excellence is what transforms a simple component into one of the most reliable and cost-effective compact heat exchange solutions. Investing in this superior heat transfer technology means investing in a system's longevity and performance.

The Sustainable Choice for the Future

As the global focus shifts towards energy efficiency and environmental responsibility, the role of efficient heat exchangers becomes even more critical. The inherent efficiency derived from the finned tube design benefits translates directly into lower energy bills and a reduced carbon footprint. By facilitating faster and more effective temperature regulation, a compact finned tube heat exchanger allows entire systems—be it a building's HVAC or an industrial cooler—to operate with less power. This makes it not just a high-performance component, but a strategic asset in building a more sustainable and energy-conscious future. Embracing this technology is a clear step towards achieving both operational excellence and environmental stewardship.