In the world of thermal management, Finned Tube Heat Exchangers stand as a cornerstone of modern engineering, providing essential solutions for a vast array of heating and cooling needs. This advanced heat transfer technology is pivotal in countless systems, from large-scale industrial plants to the commercial buildings we use every day. By dramatically increasing the surface area available for heat exchange, these devices offer a powerful and efficient method for controlling temperatures. Their design, which typically involves a series of tubes with attached fins, allows for the rapid transfer of thermal energy between a fluid inside the tubes and a gas, usually air, flowing over the outside. Let's explore the key benefits that make these exchangers an indispensable component in today's world.

Maximizing Heat Exchanger Efficiency

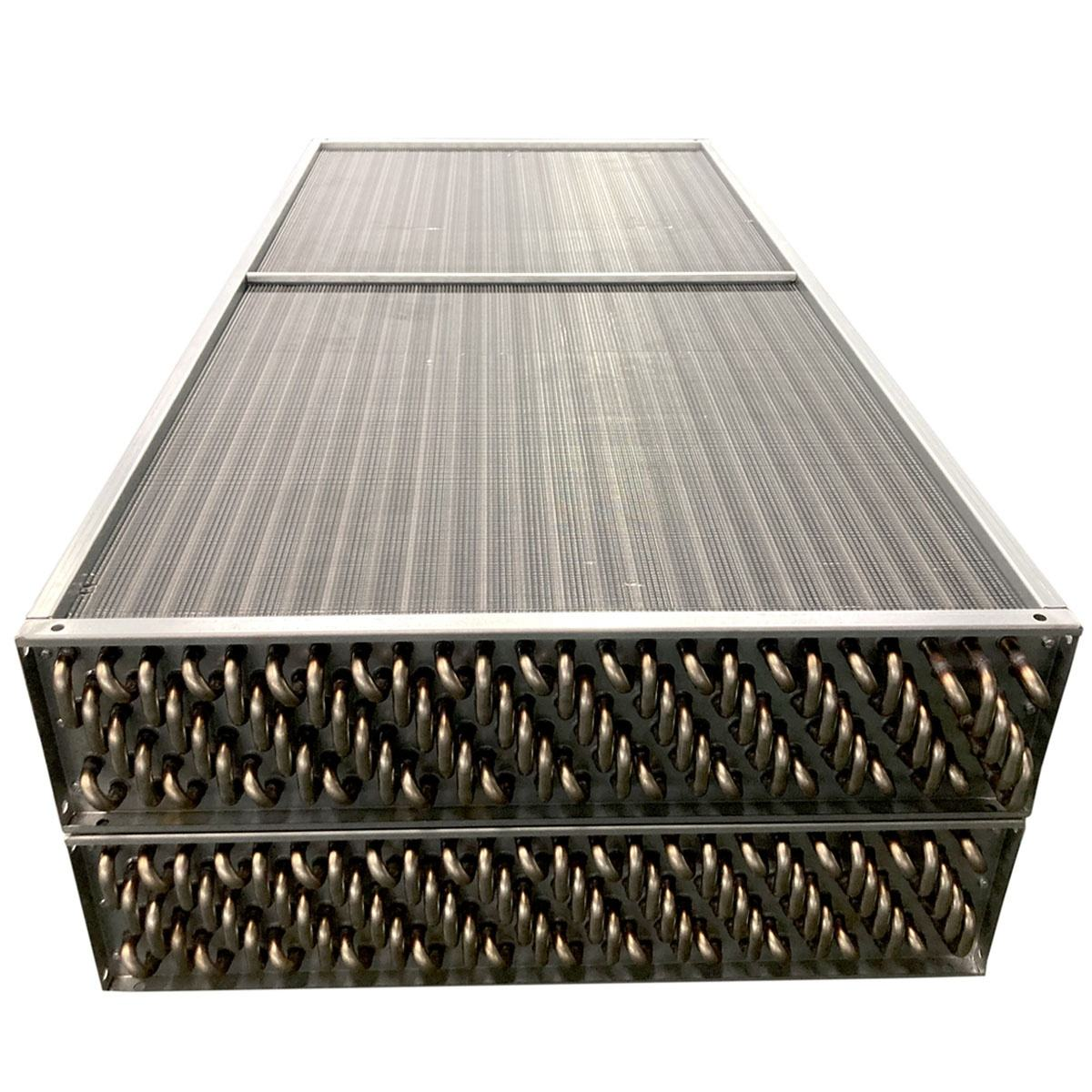

The primary advantage of a finned tube design is the significant boost in Heat Exchanger Efficiency. The fins, which extend from the outer surface of the tubes, create a much larger surface area than a bare tube could offer. This expanded area accelerates the rate of heat transfer, meaning the system can achieve the desired temperature change more quickly and within a smaller physical footprint. Our latest models are engineered with precision, featuring multiple metallic tubes and intricately connected pipes that facilitate high-volume fluid flow with remarkable velocity. This ensures that the heat exchange process is not only rapid but also highly effective, making these units a prime choice for applications where thermal performance is critical.

Versatility Across Commercial and Industrial Applications

One of the most compelling attributes of finned tube heat exchangers is their incredible versatility. They are a fundamental component in a wide range of HVAC Applications, providing the backbone for air-conditioning units in expansive commercial buildings. Beyond comfort cooling, they are also essential as Industrial Heat Exchangers. In manufacturing and processing plants, they are used for everything from cooling down machinery and process fluids to capturing waste heat for other uses. Their robust construction and reliable performance make them ideal for sophisticated refrigeration systems and other demanding Commercial Cooling Solutions, proving their adaptability across diverse and challenging environments.

A Commitment to Energy Efficient Cooling

In an era where energy consumption is a major concern, achieving Energy Efficient Cooling is a top priority for businesses and industries alike. Finned tube heat exchangers contribute directly to this goal. By improving the efficiency of the heat transfer process, they allow cooling and heating systems to operate with less energy. This means that compressors, fans, and pumps don't have to work as hard to achieve the same level of temperature control, leading to substantial reductions in electricity usage and operational costs. Investing in a high-quality heat exchanger is not just an upgrade in performance but also a smart financial and environmental decision, reducing a facility's overall carbon footprint.

Robust Design for Long-Term Reliability

The demanding conditions within industrial and commercial settings require equipment that is built to last. Finned tube heat exchangers are crafted from superior-quality materials to offer remarkable resilience against a spectrum of operating conditions. This includes handling significant temperature fluctuations and resisting corrosive environments, which is crucial for maintaining performance and integrity over time. The solid construction ensures a long service life with minimal maintenance, providing a dependable and steadfast solution you can count on for consistent temperature regulation. Furthermore, their modular design simplifies installation, maintenance, and customization, allowing for seamless integration into specific project requirements without hassle.