The shell and tube heat exchanger stands as a cornerstone of modern thermal management, offering a robust and reliable solution for a vast array of industrial processes. These devices are essential for controlling temperatures and conserving energy, making their proper selection and implementation critical for operational success. Whether you are involved in chemical processing, power generation, or manufacturing, understanding how to leverage these powerful tools can lead to significant improvements in productivity and cost-effectiveness. This guide will walk you through the key aspects of these exchangers, from their fundamental design to the latest innovations driving their performance.

A Closer Look at Shell and Tube Heat Exchanger Design

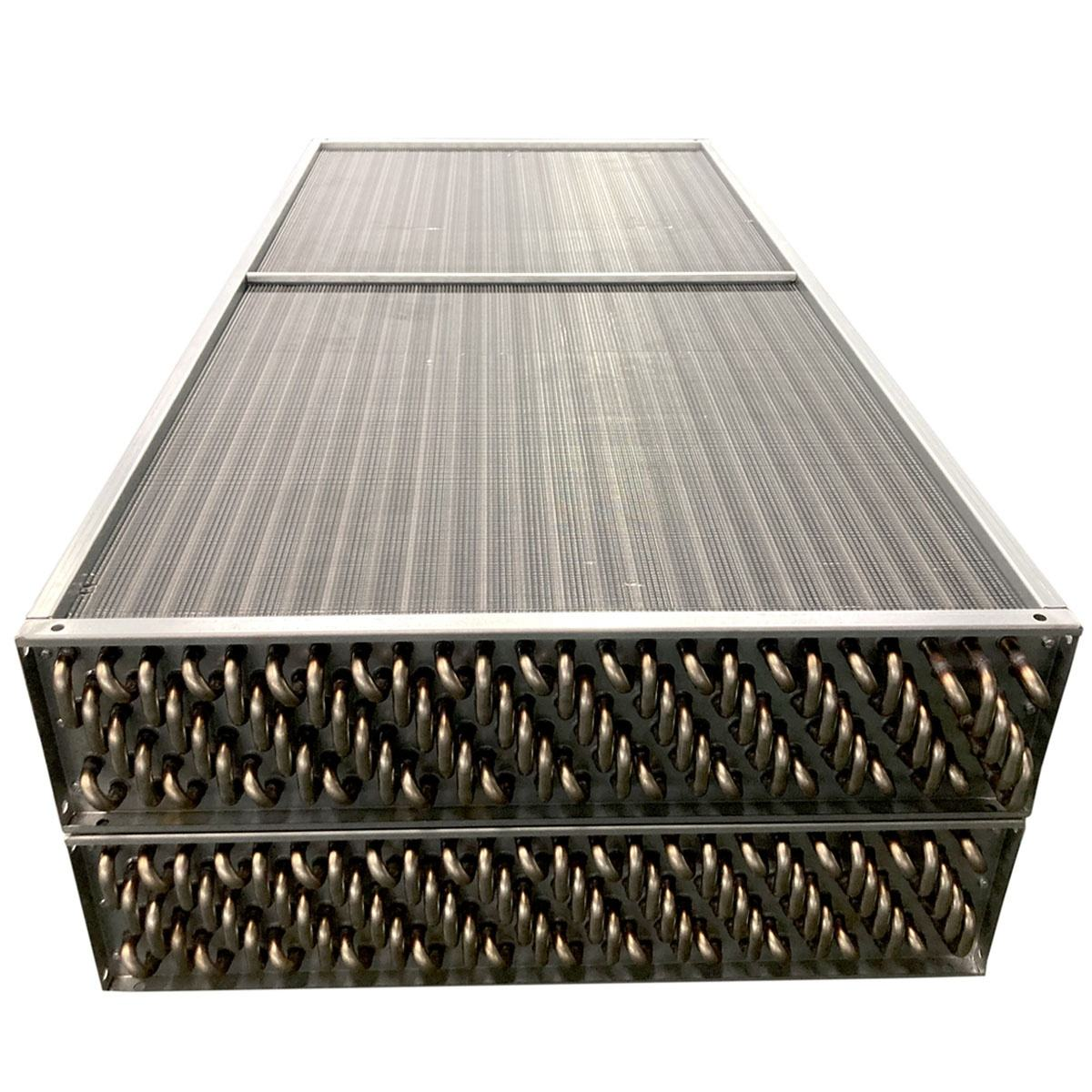

The fundamental principle behind the heat exchanger design is both simple and brilliant. It consists of a large cylindrical shell that encloses a bundle of tubes. One fluid flows through these tubes, while a second fluid flows over the outside of the tubes within the sealed shell. This arrangement creates a massive surface area for heat to transfer from the hotter fluid to the colder one without the two fluids ever coming into direct contact. The robust construction is specifically engineered to withstand high pressures and extreme temperatures, a key requirement for many demanding industrial applications. This inherent durability is a major factor in the widespread adoption of this technology, ensuring long-term reliability and minimal downtime.

Maximizing Thermal Efficiency in Your Operations

Achieving high thermal efficiency is the primary goal of any heat transfer operation, and the shell and tube model excels in this area. Efficiency is determined by how effectively heat moves from one medium to another. Factors influencing this include the flow rates of the fluids, the temperature differential, the properties of the fluids themselves, and the materials used in construction. Modern designs incorporate features like baffles within the shell to direct the flow of the outer fluid across the tube bundle, creating turbulence and maximizing contact time to enhance heat transfer. By optimizing these variables, facilities can achieve remarkable gains in energy conservation, directly translating to lower operating costs and a smaller environmental footprint. Effective thermal management is synonymous with enhanced production efficiency.

Embracing Heat Transfer Innovations and Engineering Advancements

The field of thermal management is constantly evolving, with ongoing engineering advancements pushing the boundaries of what's possible. Recent heat transfer innovations have led to significant improvements in the performance of industrial heat exchangers. This includes the development of enhanced surfaces, such as tubes with internal or external fins, which dramatically increase the surface area available for heat transfer without increasing the unit's overall size. Furthermore, the trend towards modular and customizable builds offers unprecedented flexibility. These modern designs can be tailored to very specific process needs and integrated seamlessly into existing systems, allowing engineers to create highly optimized thermal solutions that were not previously possible. This adaptability ensures that the technology remains relevant and effective in an ever-changing industrial landscape.

Choosing the Right Industrial Heat Exchangers for Your Needs

With a wide variety of industrial heat exchangers available, selecting the right one is crucial. The shell and tube heat exchanger is often the preferred choice for its versatility and strength. When selecting a unit, you must consider the specific requirements of your application, including operating pressures and temperatures, the chemical compatibility of the fluids with the construction materials, and the required rate of heat transfer. A well-chosen unit not only performs its function effectively but also contributes to the overall safety and reliability of the entire system. Investing in a high-quality, durable, and efficient heat exchanger is a strategic decision that pays dividends through enhanced performance, reduced energy consumption, and long service life, making it a vital asset for any forward-thinking industrial operation.