In today's fast-paced industrial and commercial environments, maximizing efficiency while minimizing physical footprint is a constant challenge. Engineers and facility managers are always searching for smarter ways to optimize their systems without requiring extensive space. This is where the modern compact heat exchanger comes into play, offering powerful and efficient heat exchange solutions that are perfectly suited for the demands of contemporary infrastructure. These advanced units represent a significant leap forward in thermal management technology, proving that powerful performance can indeed come in a small package.

The Advantage of a Space-Saving Design

A primary benefit driving the adoption of these units is their inherent space-saving heat exchanger design. In densely packed mechanical rooms, mobile applications, or integrated machinery, every square inch is valuable. Traditional heat exchangers can be bulky and difficult to integrate, but compact models are specifically engineered to deliver maximum thermal performance within a minimal volume. This makes them the ideal heat exchanger for small spaces, allowing for flexible installation in locations that were previously unsuitable. The evolution towards a portable heat exchanger design also enhances versatility, enabling easier transport, installation, and integration into a wide array of systems, from HVAC units to specialized industrial processes.

Finned Tube Technology: The Core of Efficiency

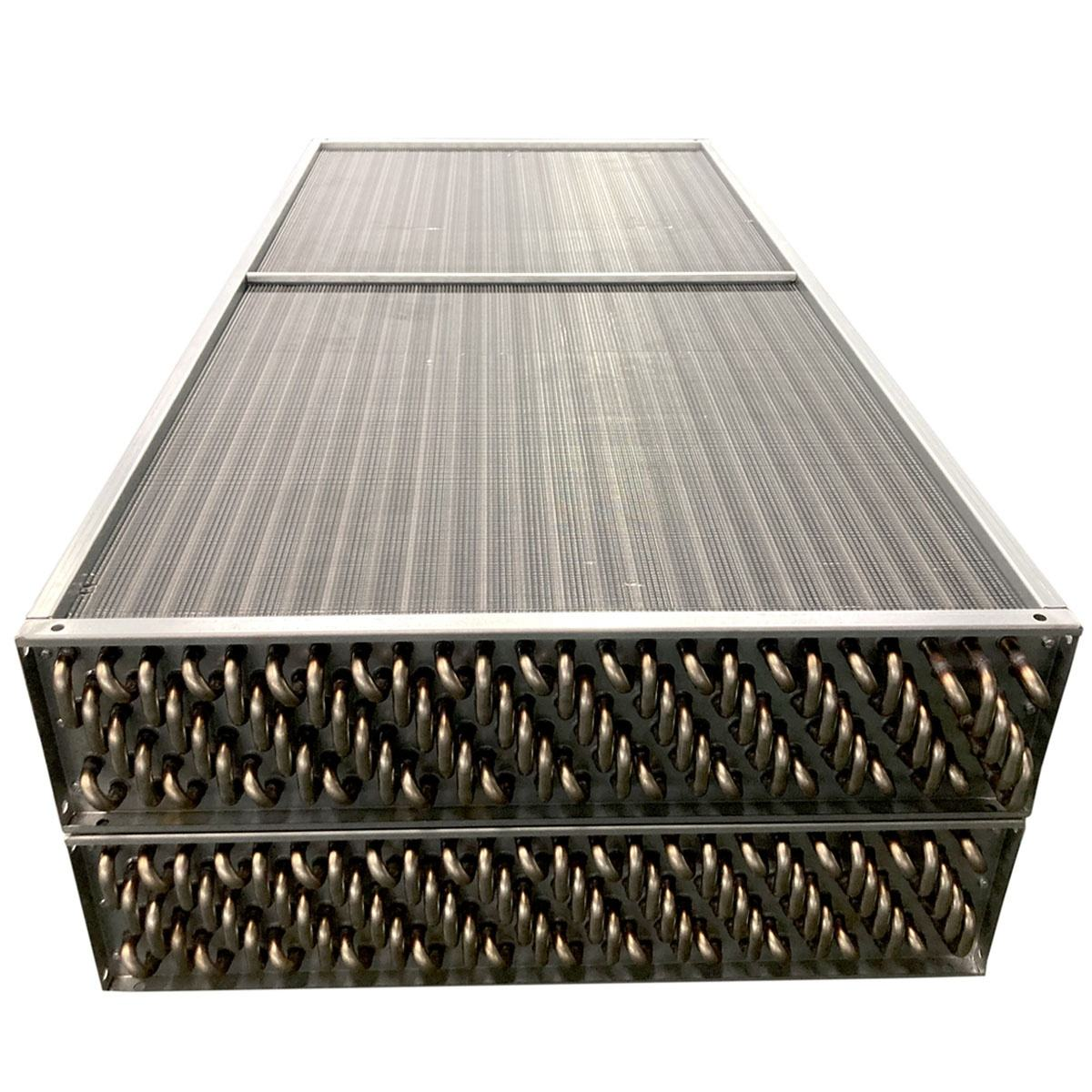

The secret behind the impressive performance of these units lies in their construction, particularly the finned tube design advantages. By attaching thin plates or fins, typically made of high-grade aluminum, to the primary tubing, the effective surface area for heat transfer is dramatically increased without expanding the unit's overall dimensions. This intelligent engineering is what makes a lightweight finned tube heat exchanger possible, reducing structural load requirements and simplifying handling. The core tubing, often crafted from durable copper or stainless steel, ensures excellent thermal conductivity and resistance to corrosion, guaranteeing a long and reliable service life even under demanding operational conditions.

Robust Performance in Industrial Applications

While their size is a key feature, these units are built for serious work. The industrial finned tube heat exchanger is designed to withstand the high pressures and temperature differentials common in heavy-duty settings. Their robust construction ensures they can manage demanding thermal loads reliably, contributing to overall system stability and efficiency. By facilitating superior heat transfer, these devices help lower energy consumption, which translates directly into reduced operational costs and a smaller carbon footprint. This alignment with modern sustainability goals makes a compact heat exchanger not just a practical choice, but an environmentally conscious one, helping industries move towards greener, more efficient operations without compromising on power.