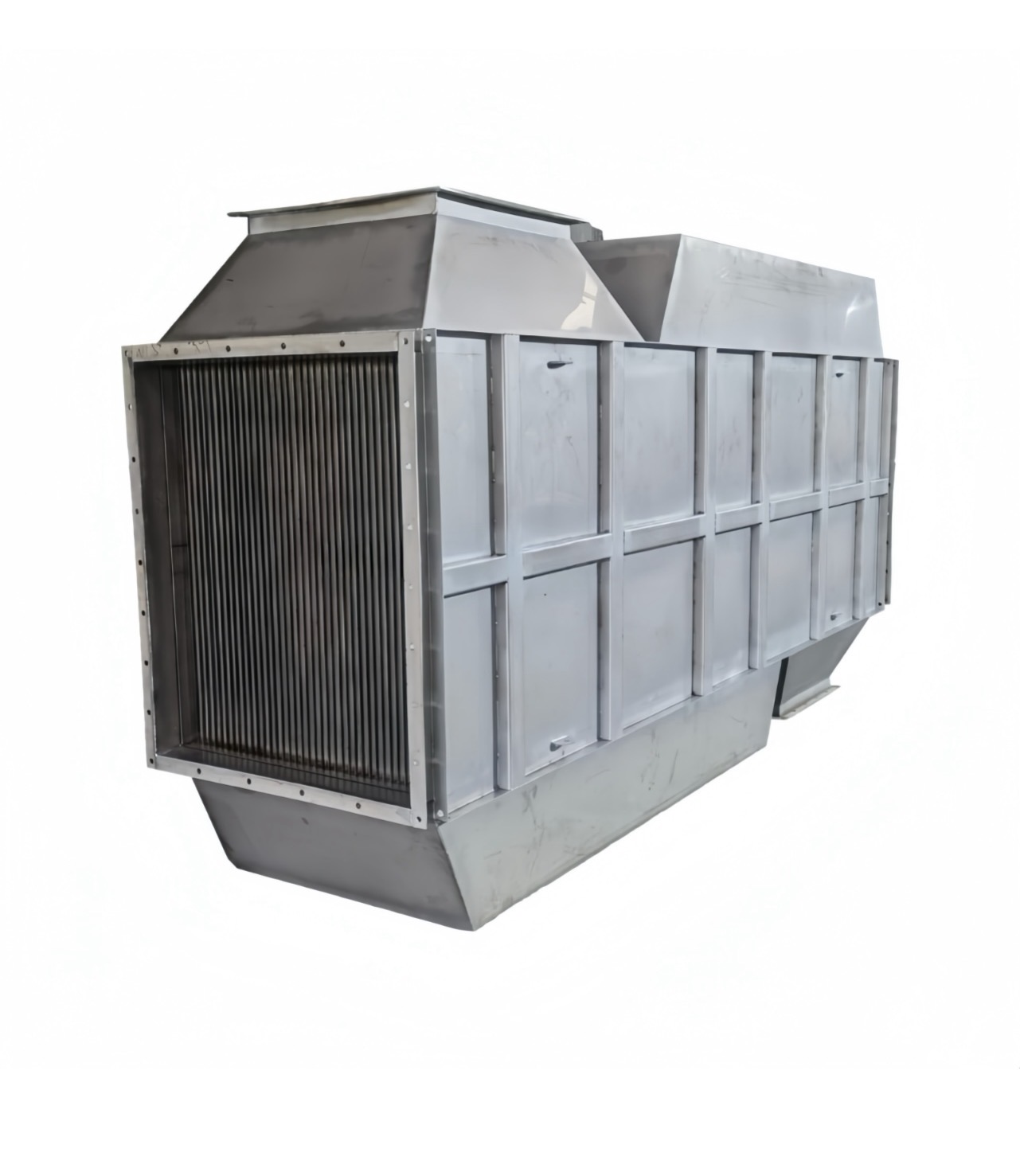

In the complex and demanding world of industrial and commercial operations, effective thermal management is not just a goal—it is a fundamental requirement for success. Achieving peak efficiency and reliability often requires solutions that go beyond standard, off-the-shelf components, which is where a Custom sized heat exchanger becomes an indispensable asset. This advanced heat exchange technology provides a tailored approach to managing thermal energy, ensuring that critical systems in HVAC, refrigeration, and diverse industrial processes operate at their optimal capacity. By precisely matching the equipment to the unique demands of an application, businesses can unlock significant, measurable improvements in performance, cost-effectiveness, and energy savings.

Why Choose Custom Heat Solutions?

While standard heat exchangers serve many general purposes, they often represent a compromise in performance, size, or material compatibility. Custom heat solutions are engineered from the ground up to meet exact specifications, thereby eliminating inefficiencies from the very start. A system designed around a Custom sized heat exchanger benefits from a perfect physical fit and meticulously calculated fluid dynamics, which are crucial for achieving superior thermal transfer optimization. This bespoke approach extends to the selection of specific materials that can withstand corrosive fluids, extreme temperatures, or high-pressure environments. Furthermore, the configuration can be adapted to unique spatial constraints or complex operational demands, ensuring that the equipment integrates seamlessly and performs reliably for its intended lifespan without costly modifications.

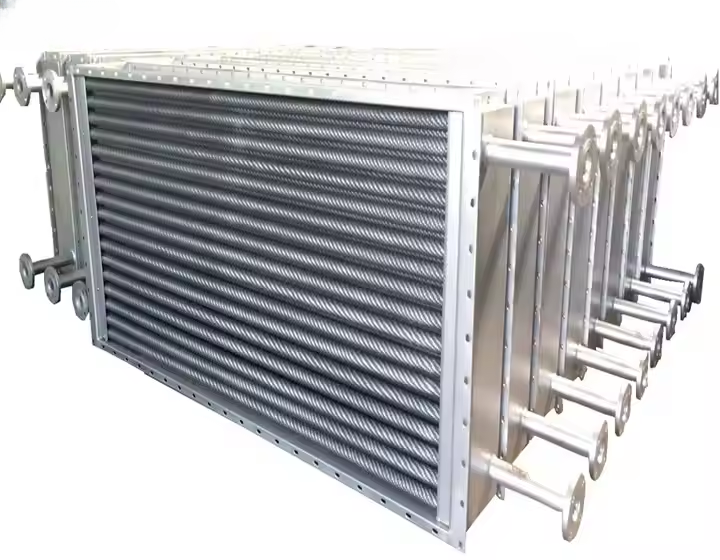

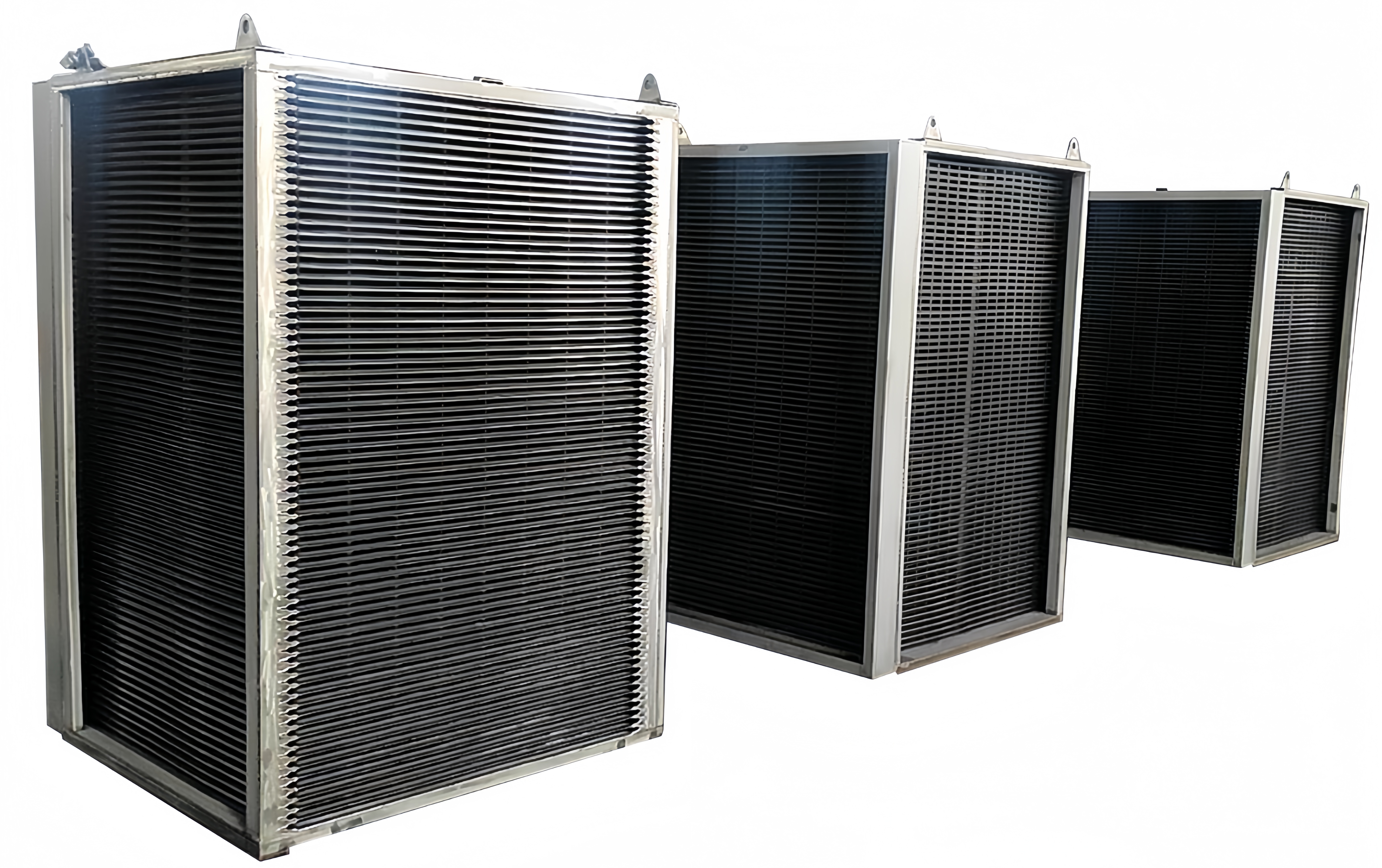

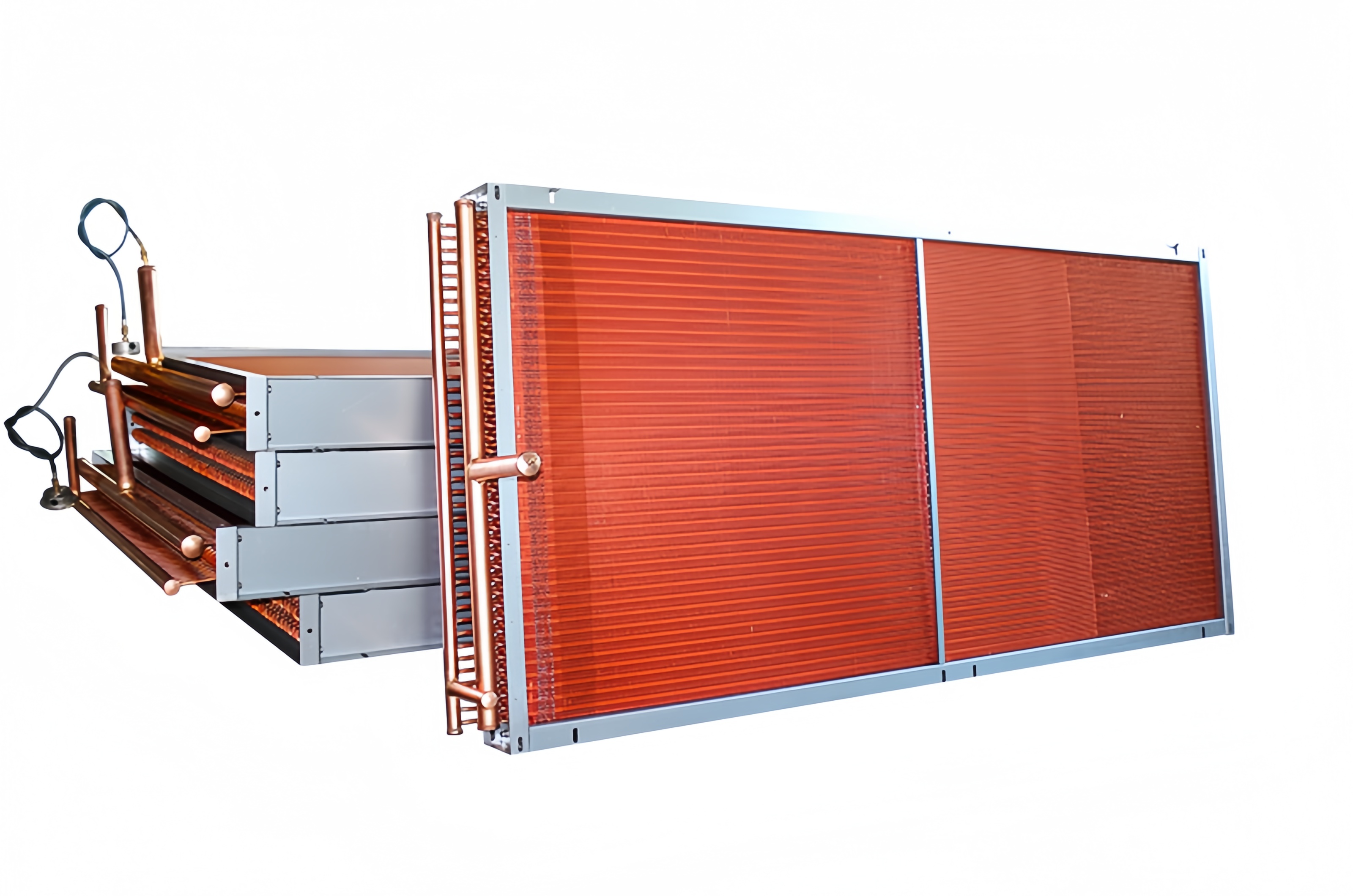

Innovations in Finned Tube Heat Exchanger Design

A prominent and highly effective example of modern heat exchange can be seen in the Finned tube heat exchanger. The core principle behind this popular design is to dramatically increase the external surface area available for heat transfer between a fluid inside the tubes and a gas flowing over them. The Finned tube design itself is a field of continuous innovation, with engineers refining fin geometry, spacing, height, and materials to maximize heat dissipation or absorption. Different fin types, such as helical, serrated, or extruded, are chosen based on the specific application to balance thermal performance with pressure drop. Proper Finned tube design is absolutely critical for thermal transfer optimization, as it ensures minimal resistance to airflow while maximizing contact with the process fluid, making it a cornerstone of advanced heat exchange technology.

Diverse Applications of Industrial Heat Exchangers

The versatility of custom solutions is evident across countless sectors. Industrial heat exchangers are fundamental components in a wide array of applications, from cooling essential lubricants in heavy machinery to condensing vapors in chemical processing plants. In modern HVAC systems, they are pivotal for conditioning air in large commercial buildings, homes, and temperature-sensitive data centers, contributing significantly to both occupant comfort and energy conservation. Within the domain of refrigeration, a precisely engineered Finned tube heat exchanger ensures the stable cooling performance required for commercial cold storage units and industrial chillers by facilitating efficient refrigerant condensation and evaporation. The ability to customize these Industrial heat exchangers for waste heat recovery applications also transforms excess thermal energy from factory processes into tangible cost savings, highlighting their essential role in sustainable and efficient industrial practices.

The Future of Thermal Management

Ultimately, investing in a Custom sized heat exchanger is a strategic decision that directly enhances operational efficiency, reduces energy consumption, and promotes long-term system reliability. Moving beyond one-size-fits-all products to embrace Custom heat solutions allows businesses to build more resilient, effective, and environmentally conscious systems. As industries continue to push the boundaries of performance and sustainability, the importance of specialized engineering and tailored thermal management will only continue to grow. This commitment to precision ensures that every system, from a compact refrigeration unit to a sprawling industrial process, can achieve its full potential through superior thermal control.