In the world of industrial operations, effective temperature control is not just a preference; it is a critical necessity. The search for optimal thermal management solutions has led to significant advancements in heat exchange technology, with the High-Efficiency Air-Cooled Heat Exchanger emerging as a powerful and versatile option. This technology stands as a cornerstone for industries aiming to achieve operational stability and efficiency, but to truly understand its value, it's essential to compare it with its primary counterpart: the water-cooled heat exchanger.

Core Operational Principles: Air vs. Water

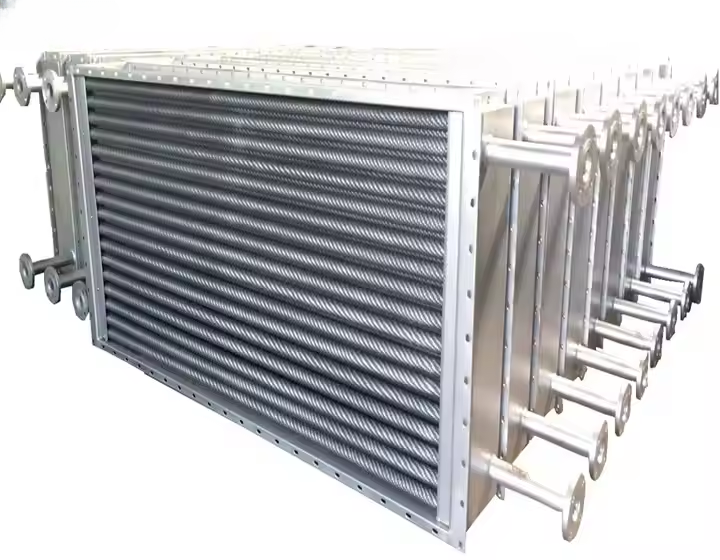

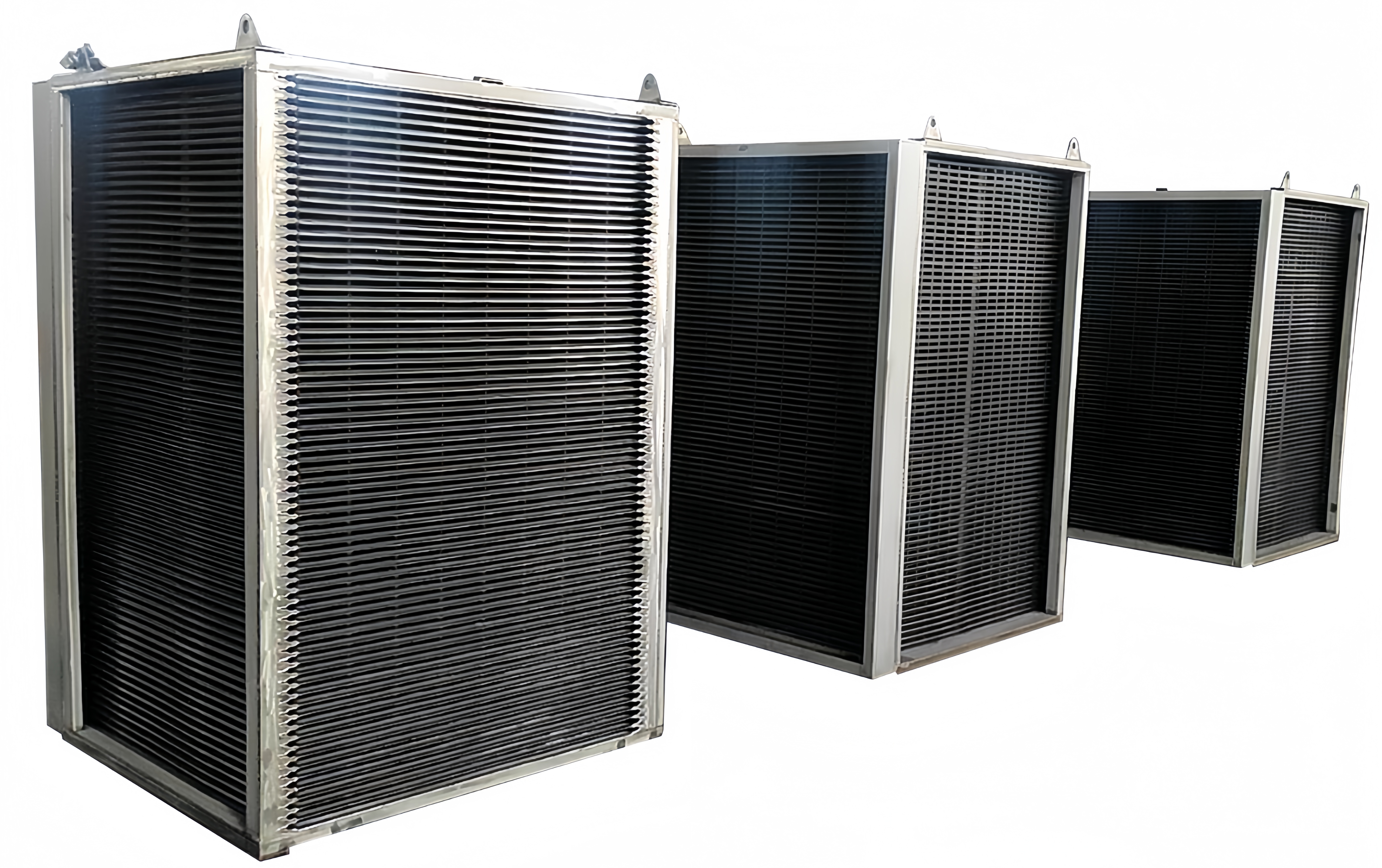

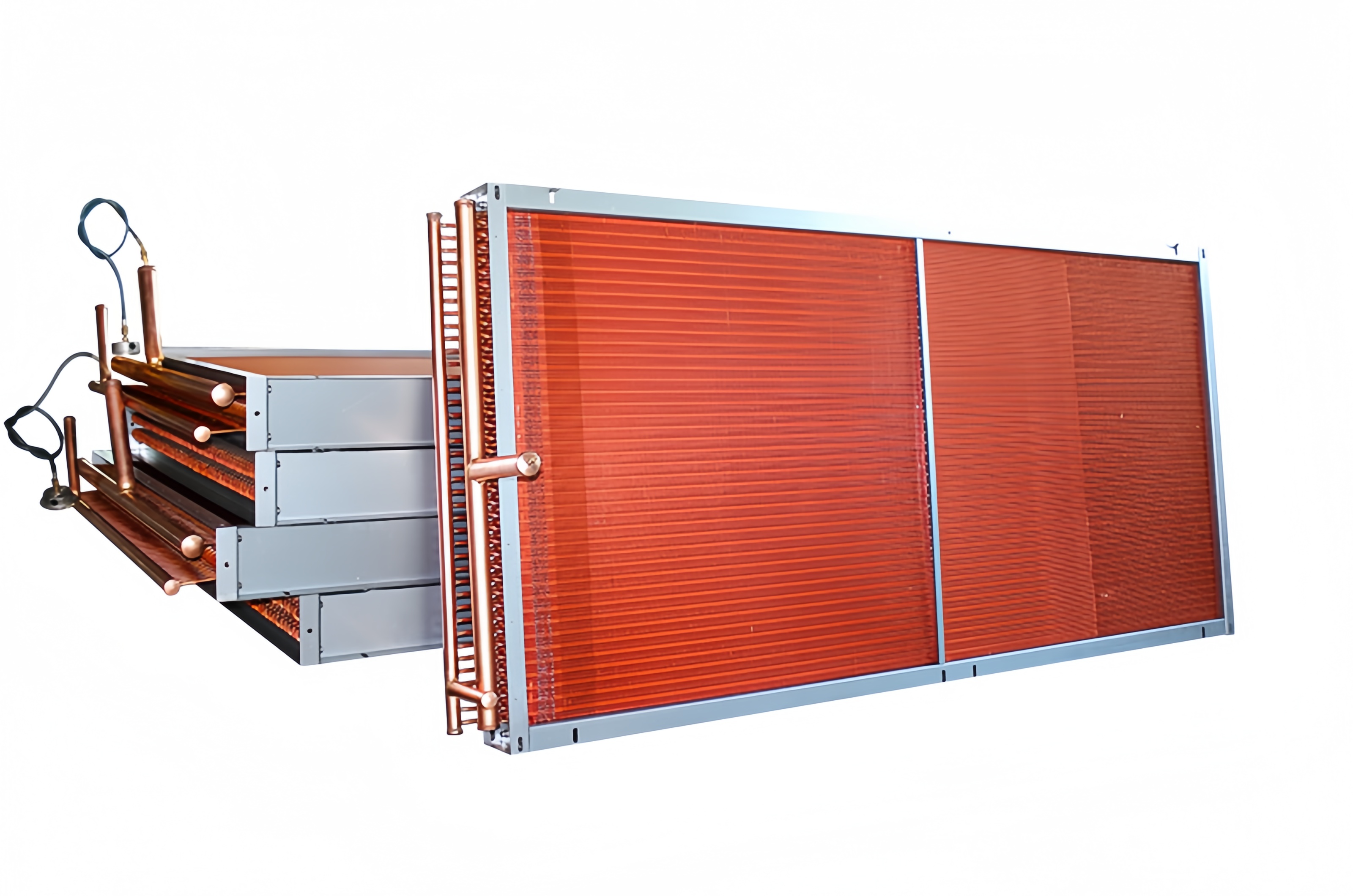

At the most fundamental level, the primary distinction lies in the cooling medium. An Air-Cooled Heat Exchanger utilizes ambient air, which is forced or drawn over a series of finned tubes containing the hot fluid. The heat transfers from the fluid, through the tube walls and fins, and into the passing air. In contrast, a water-cooled system circulates a secondary fluid, typically water or a water-glycol mix, to absorb and carry away the heat. This fundamental difference in cooling system design dictates each unit's strengths and weaknesses. Air-cooled systems offer unparalleled simplicity and independence, as they do not require a separate water source, eliminating the costs and complexities associated with water piping, pumps, and treatment. Water-cooled systems, however, often provide more consistent cooling performance because water has a higher thermal conductivity and its temperature is less variable than ambient air.

Efficiency, Cost, and Environmental Considerations

When evaluating an industrial heat exchanger, efficiency and long-term cost are paramount. Historically, water-cooled systems were considered more efficient. However, modern innovations in design, such as the optimized tube-fin configurations found in today's advanced models, have made the air-cooled type a formidable energy-saving heat exchanger. While a water-cooled unit might have a smaller initial footprint for the same capacity, the total cost of ownership can be higher due to water consumption, chemical treatment, and the energy required for pumping. From an environmental perspective, the air-cooled option presents a clear advantage by eliminating water usage, a critical factor in arid regions or areas with stringent water conservation regulations. This makes it a more sustainable choice for achieving stable thermal management without impacting local water resources.

Installation, Maintenance, and System Reliability

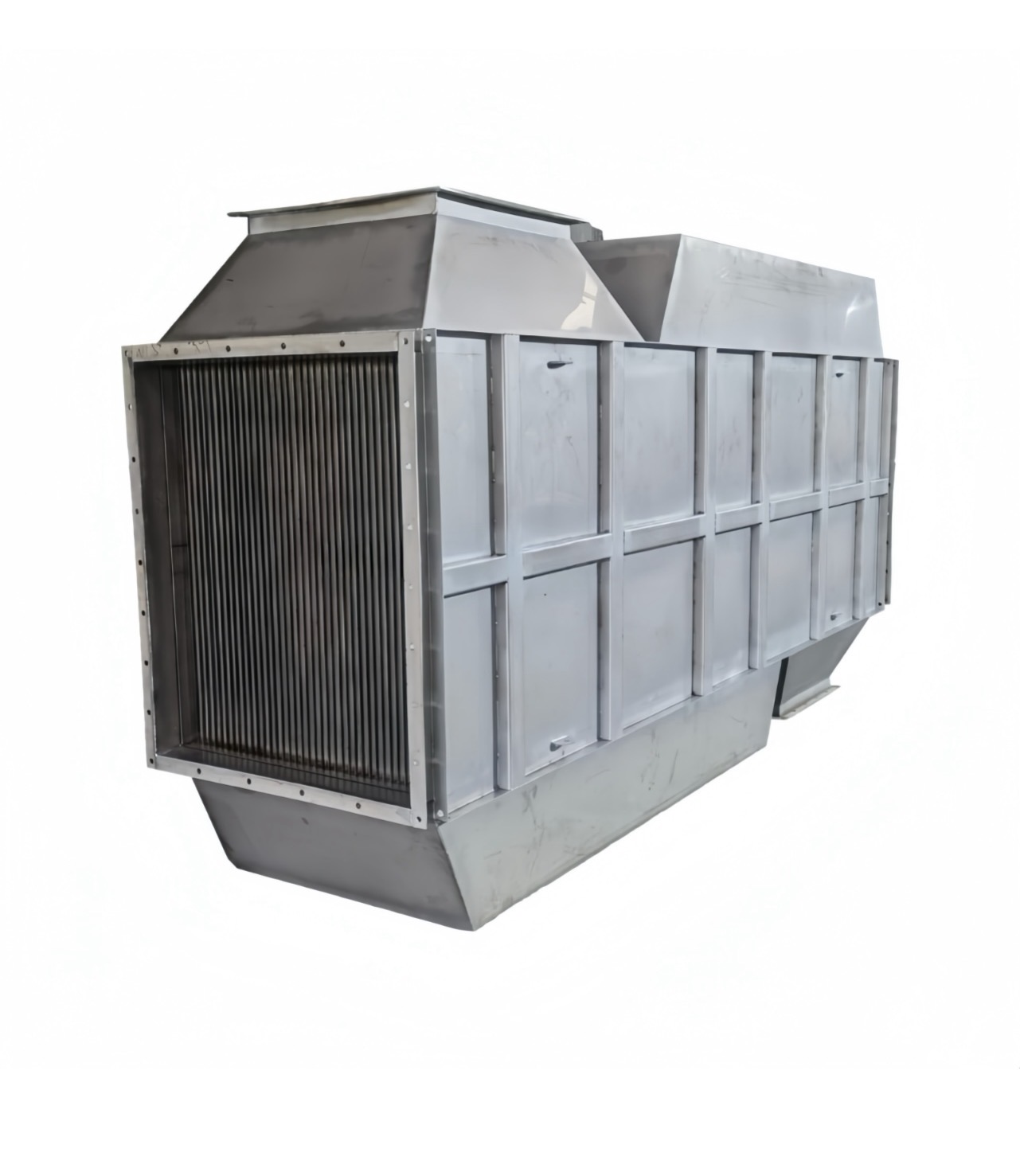

The design and installation flexibility of a modern Air-Cooled Heat Exchanger is a significant advantage. Crafted from robust materials like stainless steel or aluminum, these units are designed for durability and can be configured to fit diverse system setups, from sprawling petrochemical plants to compact HVAC units. Installation is streamlined without the need for complex plumbing. Maintenance is also substantially simpler, typically involving only the routine cleaning of fins to remove dust and debris that can impede airflow. This ensures sustained high performance with minimal downtime. Water-cooled systems, on the other hand, require more rigorous maintenance to prevent scaling, fouling, and corrosion within the tubes, which can degrade heat exchange technology and lead to costly repairs. The risk of leaks also adds a layer of complexity to their long-term management.

Choosing the Right Thermal Management Solution

The decision between an air-cooled and water-cooled system ultimately depends on specific application needs and environmental conditions. For industries like power generation, refrigeration, and oil and gas, where reliability and low operational overhead are critical, the High-Efficiency Air-Cooled Heat Exchanger is often the ideal choice. Its ability to provide consistent cooling without reliance on a water supply makes it a versatile and cost-effective solution. When considering a new cooling system design, factors such as geographic location, utility availability, maintenance capabilities, and long-term operating budget must be weighed. The modern air-cooled unit, with its blend of efficiency, durability, and low maintenance, represents a forward-thinking investment in achieving stable and sustainable industrial operations.