In the world of industrial processes, achieving optimal heat transfer performance is paramount for efficiency, cost-effectiveness, and sustainability. Modern industrial heat transfer solutions are constantly evolving to meet these demands, with a focus on materials and designs that push the boundaries of what's possible. Among these innovations, one technology stands out for its remarkable capabilities: extruded aluminum fin tubes. These components are at the heart of many advanced systems, offering a significant leap forward in managing thermal energy and setting a new standard for performance.

1. Unlocking Superior Thermal Efficiency

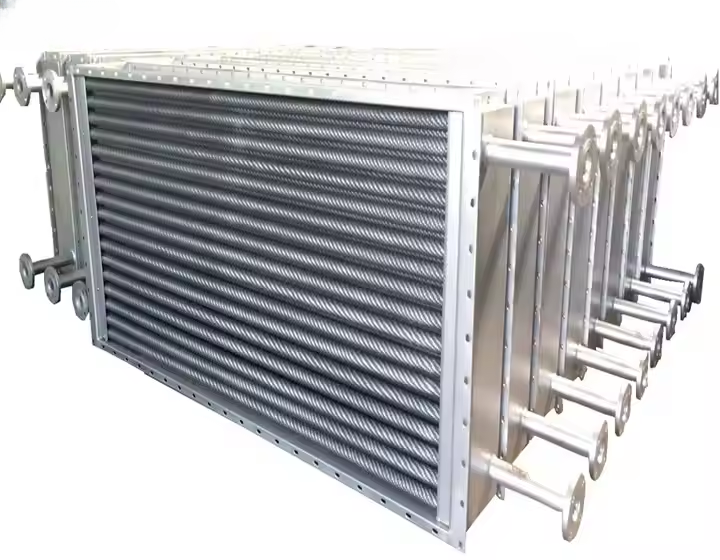

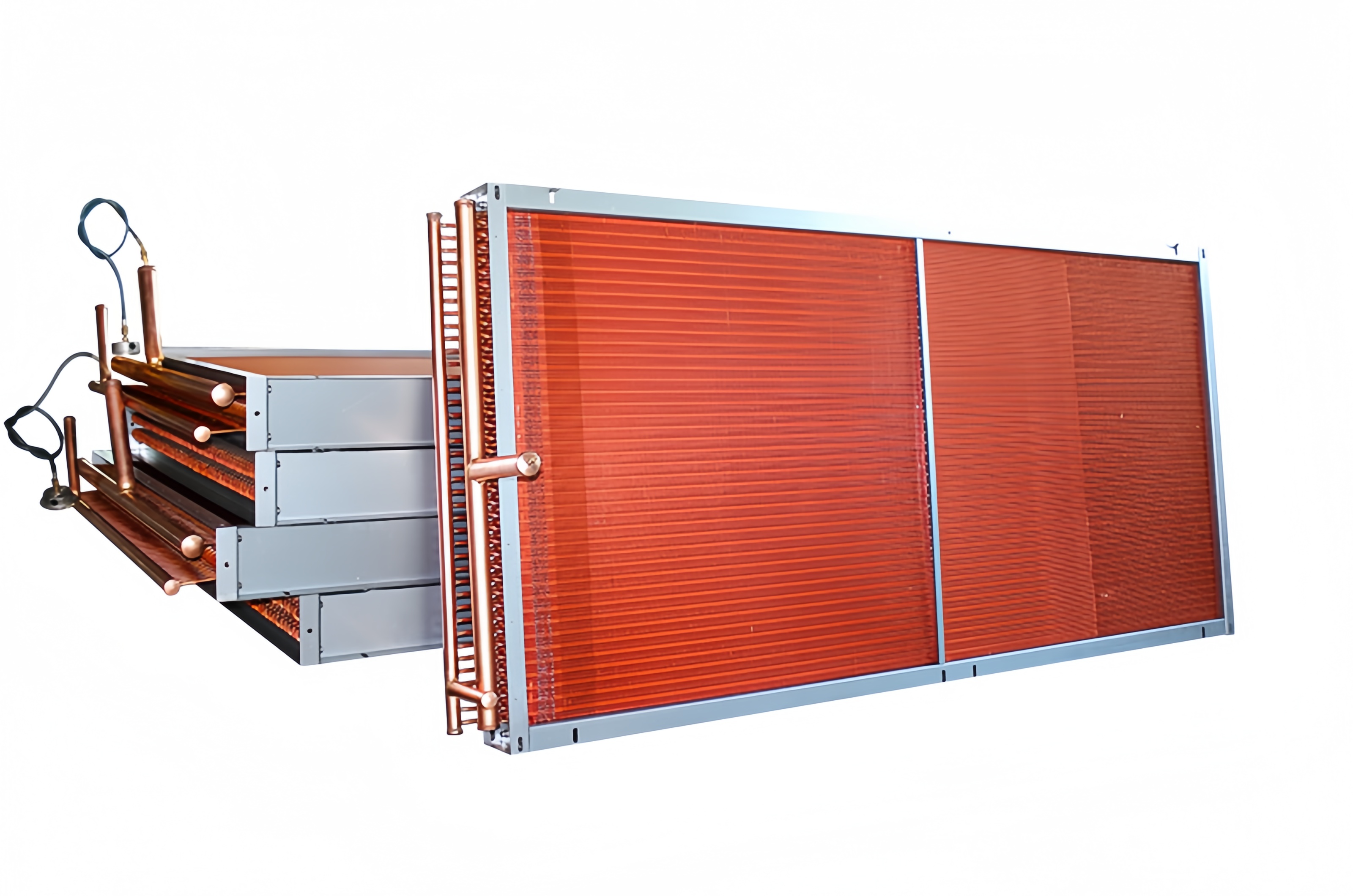

The primary advantage of extruded aluminum finned tubes lies in their ability to function as enhanced heat transfer tubing. The design is meticulously engineered to maximize the surface area available for heat exchange. Crafted with precision, these tubes feature a sleek aluminum surface that isn't just for aesthetics; it plays a crucial role in boosting thermal conductivity. This innovative construction ensures that heat moves efficiently from the internal fluid to the surrounding environment, leading to a dramatic improvement in overall heat transfer efficiency. For any system where thermal management is critical, this level of performance is a game-changer, reducing energy consumption and operational costs.

2. The Innovation of Advanced Finned Pipe Technology

At the core of this superior performance is advanced finned pipe technology. Unlike other manufacturing methods where fins are attached separately, the extrusion process creates a seamless, integral bond between the core tube and the fins. This method eliminates the air gap that can occur in other finned tube types, which often acts as a thermal barrier and impedes performance. The result is consistent and highly reliable fin-to-tube contact, ensuring an unimpeded path for heat flow. The tightly packed fins, a signature of this technology, further enhance airflow and maximize heat rejection, making this a cornerstone of modern finned tube heat exchangers.

3. Built for Durability in Demanding Environments

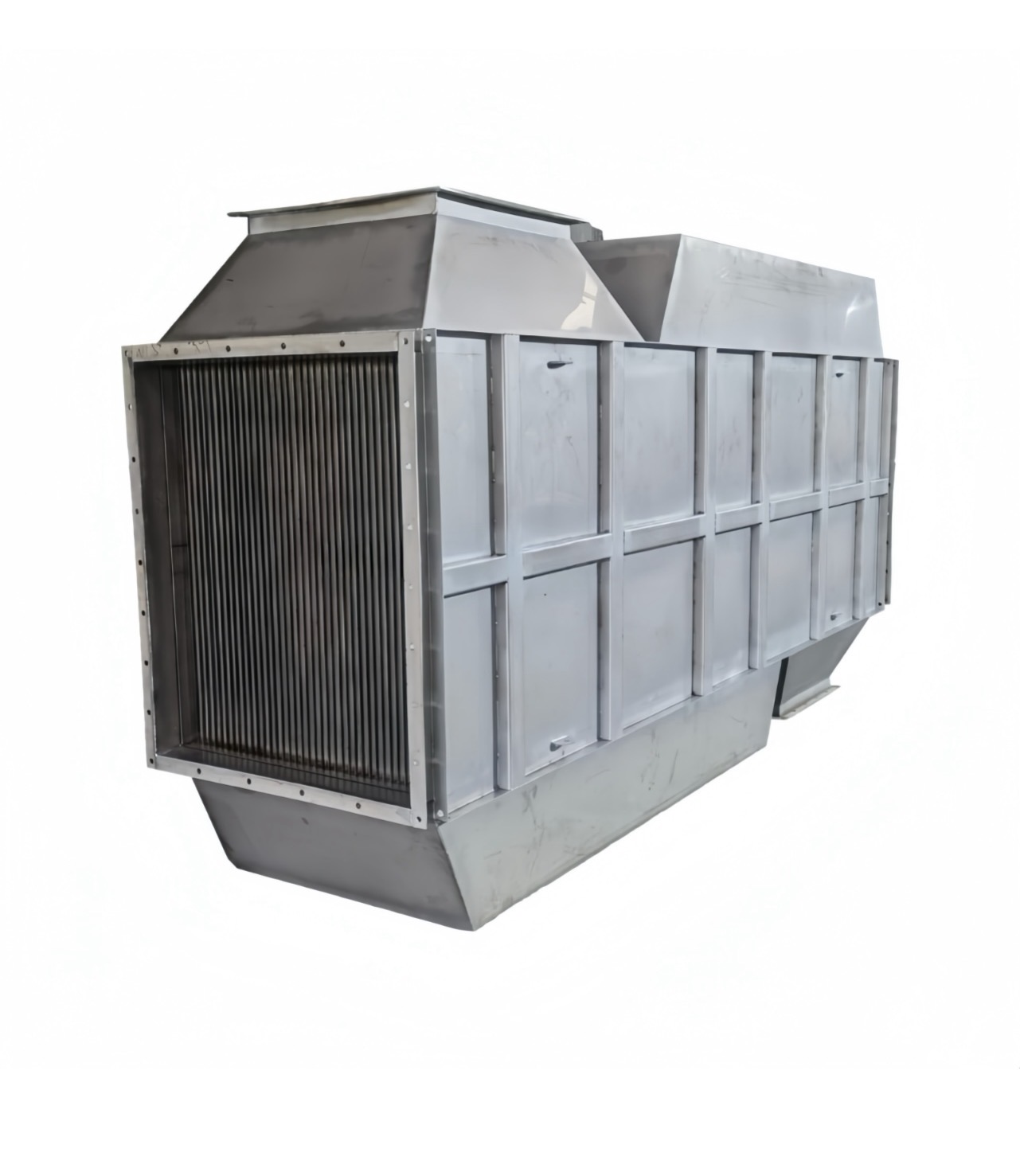

Industrial applications are often unforgiving, exposing components to harsh conditions, moisture, and corrosive substances. Extruded aluminum industrial finned tubing is specifically designed to thrive in these environments. Aluminum's natural corrosion-resistant properties form a protective oxide layer, ensuring long-term durability and minimal maintenance requirements. This inherent robustness means a longer service life for the entire system, which translates to reduced downtime and lower replacement costs over the equipment's lifetime. Whether operating in a chemical plant, a power generation facility, or a large-scale HVAC system, these tubes stand the test of time, providing reliable performance year after year.

4. Versatility Across Numerous Finned Tubing Applications

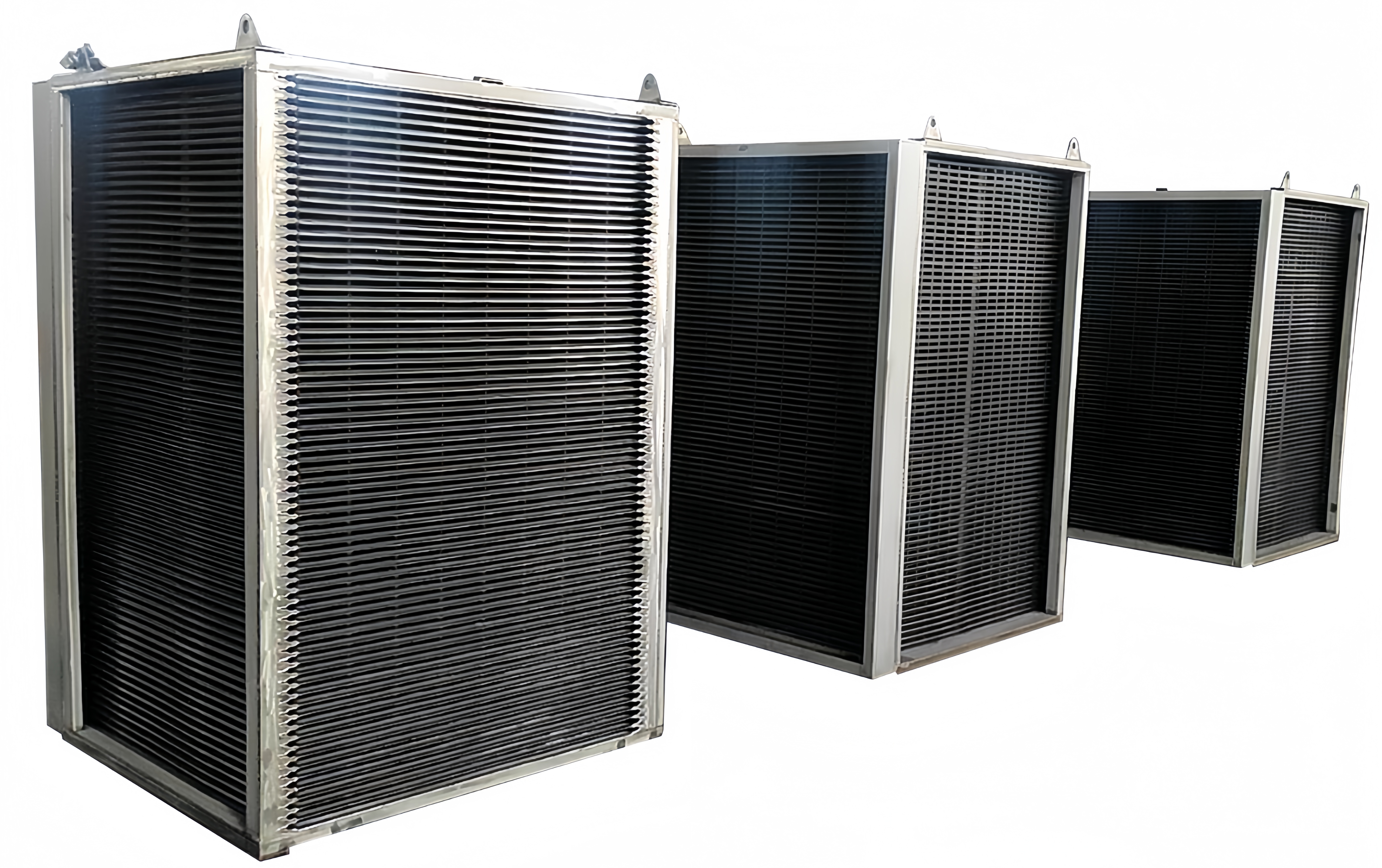

The exceptional benefits of extruded aluminum fin tubes extend across a wide spectrum of finned tubing applications. Their lightweight yet strong nature makes them ideal for everything from sophisticated HVAC systems to heavy-duty industrial radiators and air coolers. Furthermore, they are becoming increasingly vital in the renewable energy sector, particularly in geothermal and solar thermal systems where efficient heat exchange is key to viability. This versatility allows engineers and designers to leverage a single, high-performance solution for diverse thermal management challenges, making it a future-proof investment for any project aiming to optimize its heat transfer performance.

5. A Sustainable and Future-Proof Solution

Beyond raw performance and durability, choosing extruded aluminum fin tubes is a step towards more sustainable operations. The enhanced heat transfer efficiency directly leads to lower energy consumption, reducing the carbon footprint of industrial processes. Aluminum itself is a highly recyclable material, aligning with circular economy principles. As industries globally move towards greener technologies, investing in components that harmonize innovation, sustainability, and top-tier performance is crucial. These fin tubes provide a solution that not only meets today's demanding requirements but also anticipates the needs of a more energy-conscious future.