In today's industrial and commercial landscapes, the demand for an effective Energy saving heat exchanger has never been greater. As businesses strive to reduce operational costs and minimize their environmental footprint, optimizing thermal processes has become a top priority. These sophisticated devices are at the forefront of this movement, offering a practical and powerful way to manage heat. By facilitating the transfer of thermal energy from one medium to another, they play a critical role in a vast range of applications, from large-scale manufacturing to commercial HVAC systems, ensuring that valuable energy is recycled rather than wasted.

Understanding the Finned Tube Heat Exchanger

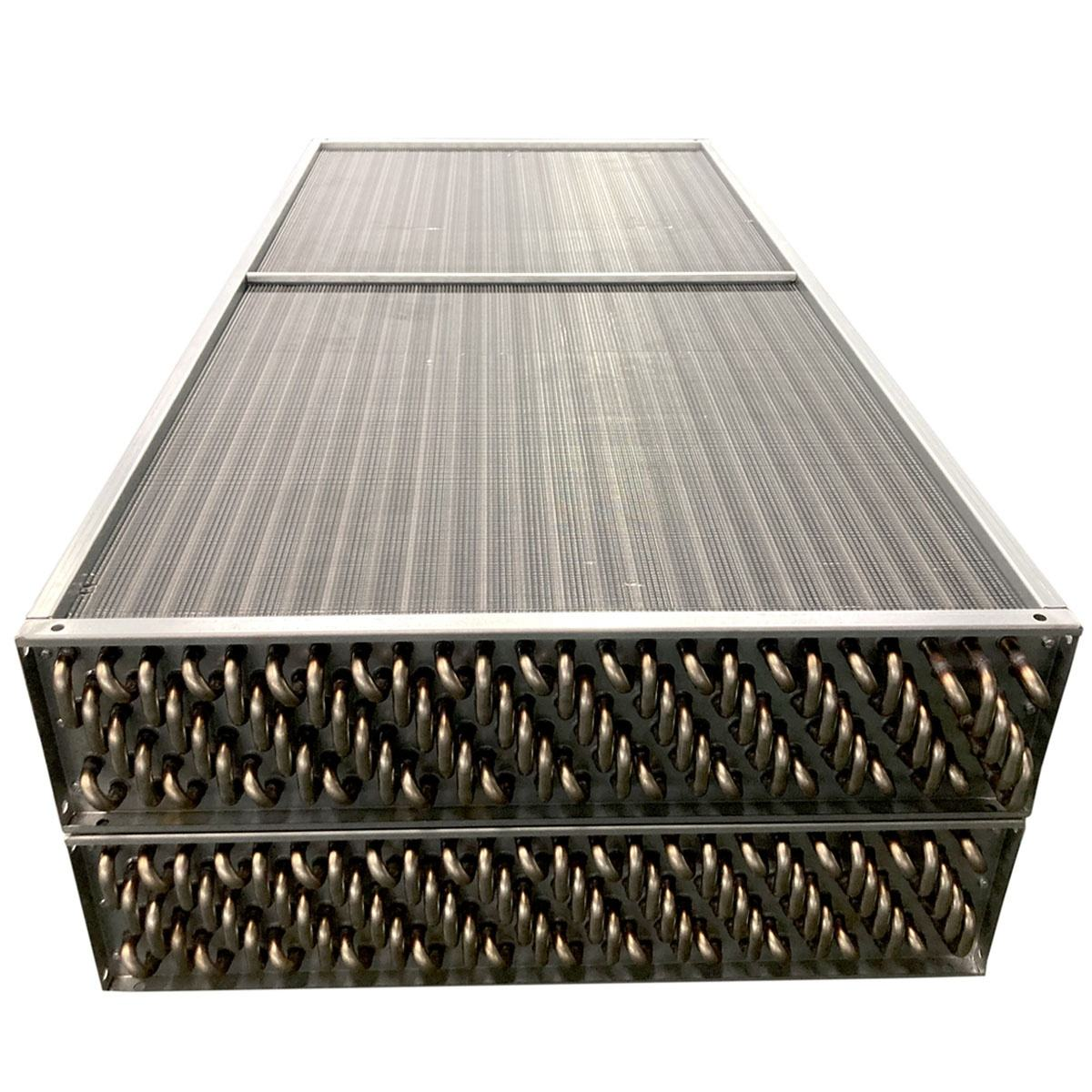

A standout in this field is the Finned tube heat exchanger. Its innovative design is the key to its superior performance. By attaching a series of fins to the exterior of the core tubes, the device's surface area is dramatically increased. This expanded surface area allows for a much faster and more effective rate of heat transfer between the fluid inside the tubes and the air or gas flowing over them. This simple yet ingenious enhancement is what drives a significant boost in Heat exchanger efficiency. Furthermore, modern designs are often compact, reducing installation space requirements without sacrificing performance, making them ideal for both new projects and retrofitting existing facilities.

Mastering Air to Fluid Heat Exchange

The primary function of these devices often involves Air to fluid heat exchange. This process is fundamental to countless systems we rely on daily. Consider a standard air conditioning unit: a refrigerant fluid absorbs heat from the indoor air, and an outdoor heat exchanger then dissipates that heat into the atmosphere. In an industrial setting, this could involve cooling hot machinery with a flow of ambient air or using a heated fluid to warm air for a drying process. The effectiveness of this transfer is paramount for the overall system's performance, and a high-quality exchanger ensures the process is completed with minimal energy loss.

The Power of Thermal Energy Recovery

One of the most compelling benefits of advanced heat exchangers is their ability to facilitate Thermal energy recovery. Many industrial processes generate enormous amounts of waste heat that is typically vented into the atmosphere. This represents a significant loss of energy and money. By implementing a high-efficiency heat exchanger, this waste heat can be captured and repurposed. For example, the hot exhaust from a furnace can be used to preheat the incoming combustion air, reducing the amount of fuel needed to reach the required temperature. This process of Thermal energy recovery not only leads to substantial cost savings but also contributes to a more sustainable operation by lowering overall energy consumption.

Optimizing with Modern Heat Exchange Systems

An individual heat exchanger is often a component within larger, more complex Heat exchange systems. To achieve maximum benefit, the entire system must be designed for performance and reliability. This means selecting components constructed from high-grade, durable materials that can withstand harsh operating environments, resist corrosion, and guarantee a long service life. Integrated Heat exchange systems are meticulously engineered to ensure all parts work in harmony, delivering superior thermal management across an entire facility. From industrial cooling units to waste heat recovery setups, a well-designed system is a cornerstone of modern operational efficiency, ensuring smooth, consistent, and cost-effective performance.

The Future of Efficient Thermal Management

Ultimately, investing in advanced thermal technology is about more than just a single piece of equipment; it's a strategic decision to enhance overall operational effectiveness. By prioritizing high Heat exchanger efficiency and embracing technologies like the Finned tube heat exchanger, businesses can unlock significant savings and improve their sustainability credentials. These systems represent the pinnacle of thermal management sophistication, providing a reliable, cost-effective, and powerful solution for any industry looking to optimize its energy use and stay competitive in a resource-conscious world.