Introduction

Heat exchangers play a vital role in many industries, particularly in maritime applications. A notable example is the Asphalt Splendor, a chemical tanker that relies on cutting-edge heat management solutions. The focus of this article is on the tube heat exchanger design, a crucial element in ensuring efficient thermal performance of heat exchangers at sea.

Understanding Bare Tube Heat Exchangers

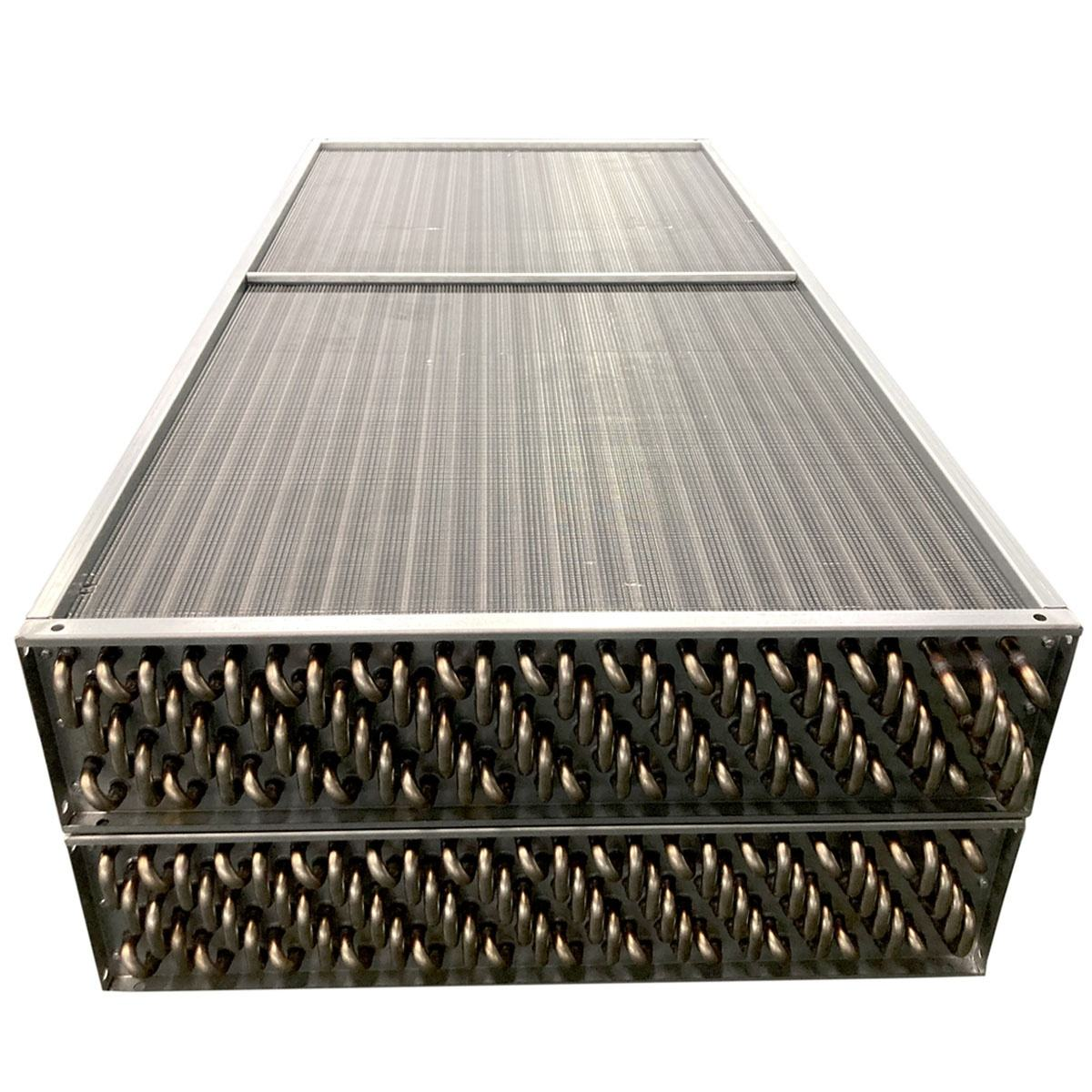

Bare tube heat exchangers are widely used in industrial heat exchangers due to their simplicity and high efficiency. Made from materials like stainless steel, carbon steel, and titanium alloys, these exchangers are designed to withstand high pressures and corrosive conditions, making them ideal for vessels like the Asphalt Splendor. The fineless design contributes to enhanced pressure resistance and reduced clogging risks, ensuring the cleanliness and efficiency necessary for maritime operations.

Heat Exchanger Types

Various heat exchanger types exist, but bare tube heat exchangers stand out for their adaptability in challenging environments. Custom heat exchanger solutions offered by Wuxi Machinery Manufacturing Co., Ltd. include a fineless design, allowing for high-viscosity fluid handling, which is essential for ships carrying viscous cargo like asphalt. The customizable pipe diameter and length, along with versatile connection methods such as flange, thread, and welded structures, cater to diverse operational needs.

Applications and Efficiency

Bare tube heat exchanger applications aboard vessels range from crude oil heating and reactor heat exchange to HVAC systems. By maintaining peak performance, these heat exchangers contribute positively to environmental initiatives through effective waste heat recovery and wastewater treatment. The robust construction and high thermal performance of heat exchangers ensure reliable operation even under extreme conditions.

Customized Solutions for Maritime Needs

Wuxi Machinery Manufacturing Co., Ltd. excels in offering tailored heat exchanger solutions for the maritime industry. The Asphalt Splendor benefits from special material selection and optimized tube arrangements, enhancing heat exchange efficiency and longevity despite the ocean's harsh conditions. Ships benefit from tailored solutions, ensuring continued successful operation in diverse ocean conditions.

Quality Assurance and Certifications

Quality is a priority for Wuxi Machinery Manufacturing Co., Ltd., with ISO 9001 certification and rigorous factory testing ensuring top-notch products. Additional pressure vessel certifications, such as ASME and PED, offer further assurance of robust technical assistance for installation and maintenance needs. This dedication to quality helps ships like Asphalt Splendor rely on dependable heat exchangers for their maritime ventures.

Conclusion

Bare tube heat exchangers are essential for the efficient operation of vessels in the maritime industry. By choosing high-quality materials and innovative designs, such as those offered by Wuxi Machinery Manufacturing Co., Ltd., ship operators can ensure the safety, efficiency, and longevity of their vessels. With the tailored solutions available, industrial heat exchanger needs can be met, paving the way for successful ocean endeavors.