Challenges in Industrial Heat Recovery

In industrial settings, particularly steel plants, there is a persistent challenge of dealing with waste heat emitted from flue gases. These gases, often overlooked for their potential, carry valuable energy that typically ends up being wasted. Conventional heat exchangers are often inefficient in capturing heat from low-temperature flue gases, primarily due to the temperature limitations and susceptibility to corrosion and fouling. Additionally, these heat exchangers fail to utilize the latent heat contained within the water vapor of exhaust gases, leading to suboptimal energy recovery and increased costs.

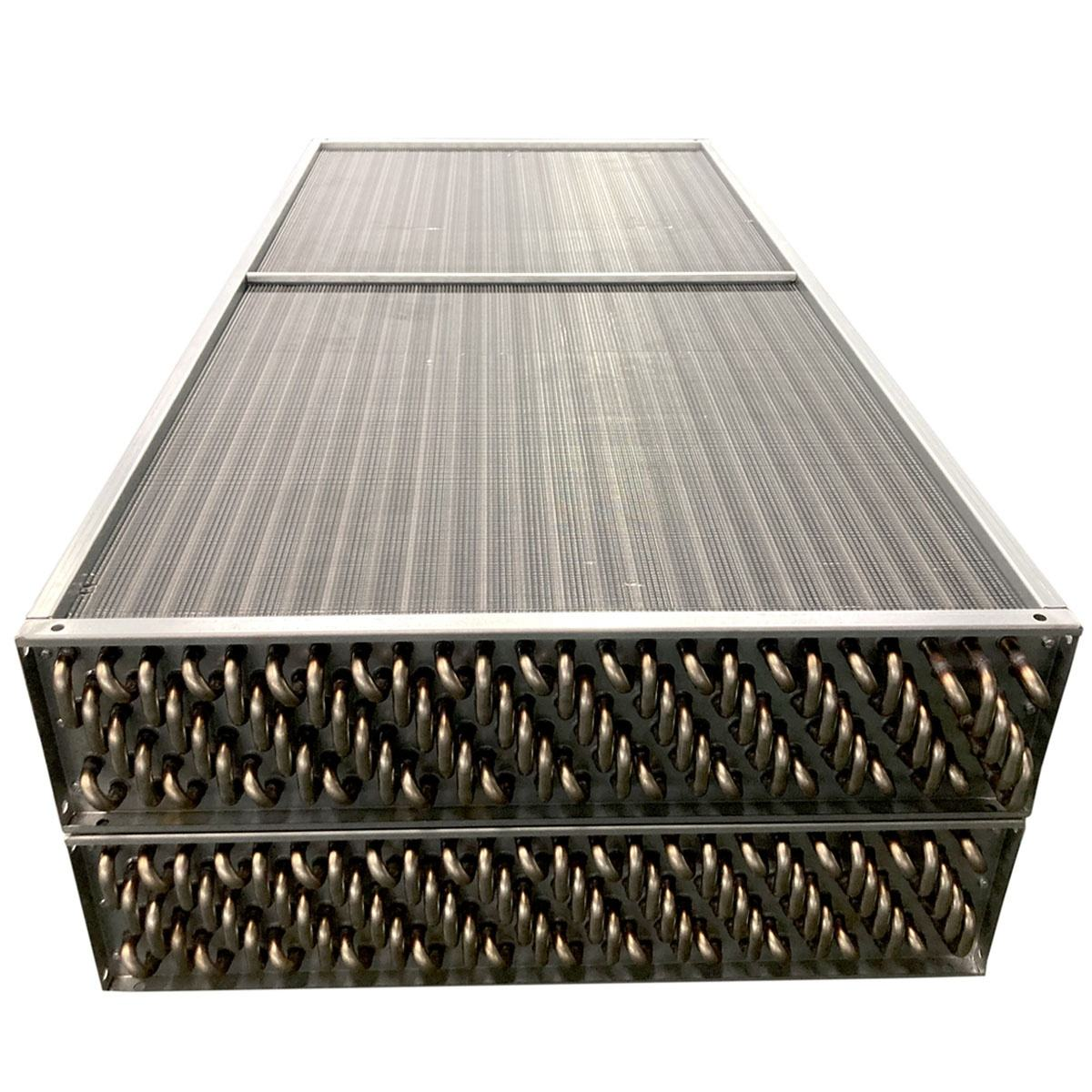

Innovative Solution: Low-Temperature Flue Gas Heat Exchanger

The Low-Temperature Flue Gas Heat Exchanger provides a compelling solution to the challenges mentioned above. This cutting-edge technology operates effectively below 250°C (482°F) and is designed to capture residual heat from cooled flue gases, which conventional systems struggle to manage. With unique features such as condensing capability and acid dew point resistance, it transforms low-grade heat, previously considered waste, into valuable energy. The exchanger supports combustion air preheating, process water heating, and even electricity generation through systems like the Organic Rankine Cycle.

Enhancing Efficiency and Sustainability

One of the standout qualities of the Low-Temperature Flue Gas Heat Exchanger is its versatility and adaptability across various industries. While steel production is a primary beneficiary, the technology is equally effective in district heating, food and beverage processing, and marine exhaust gas recycling. By optimizing the thermal gradient through microchannel and plate-fin designs, this exchanger ensures peak efficiency in diverse thermal scenarios, significantly enhancing sustainability. The modular and compact design allows for easy retrofitting into existing exhaust stacks without substantial overhauls, making it an ideal choice for companies looking to enhance heat exchanger efficiency.

With advancements such as hybrid systems integrating heat pumps for ultra-low-temperature recovery and smart sensors for AI-driven optimization on the horizon, the future of industrial heat exchangers seems promising. The Low-Temperature Flue Gas Heat Exchanger stands at the forefront of these developments, enabling industries to cut costs, reduce emissions, and achieve unprecedented levels of thermal efficiency.