The Cornerstone of Industrial Thermal Management

In the landscape of modern industry, precise temperature control is not just a preference but a necessity for safety, efficiency, and product quality. At the heart of these critical operations lies the Shell and Tube Heat Exchanger, a robust and highly effective device designed for superior thermal regulation. This technology serves as a fundamental component in countless processes, enabling the transfer of heat between two fluids without allowing them to mix. As one of the most versatile and efficient heat exchangers available, its application spans across numerous sectors, solidifying its role as an indispensable tool for engineers and plant managers seeking reliable performance and operational excellence.

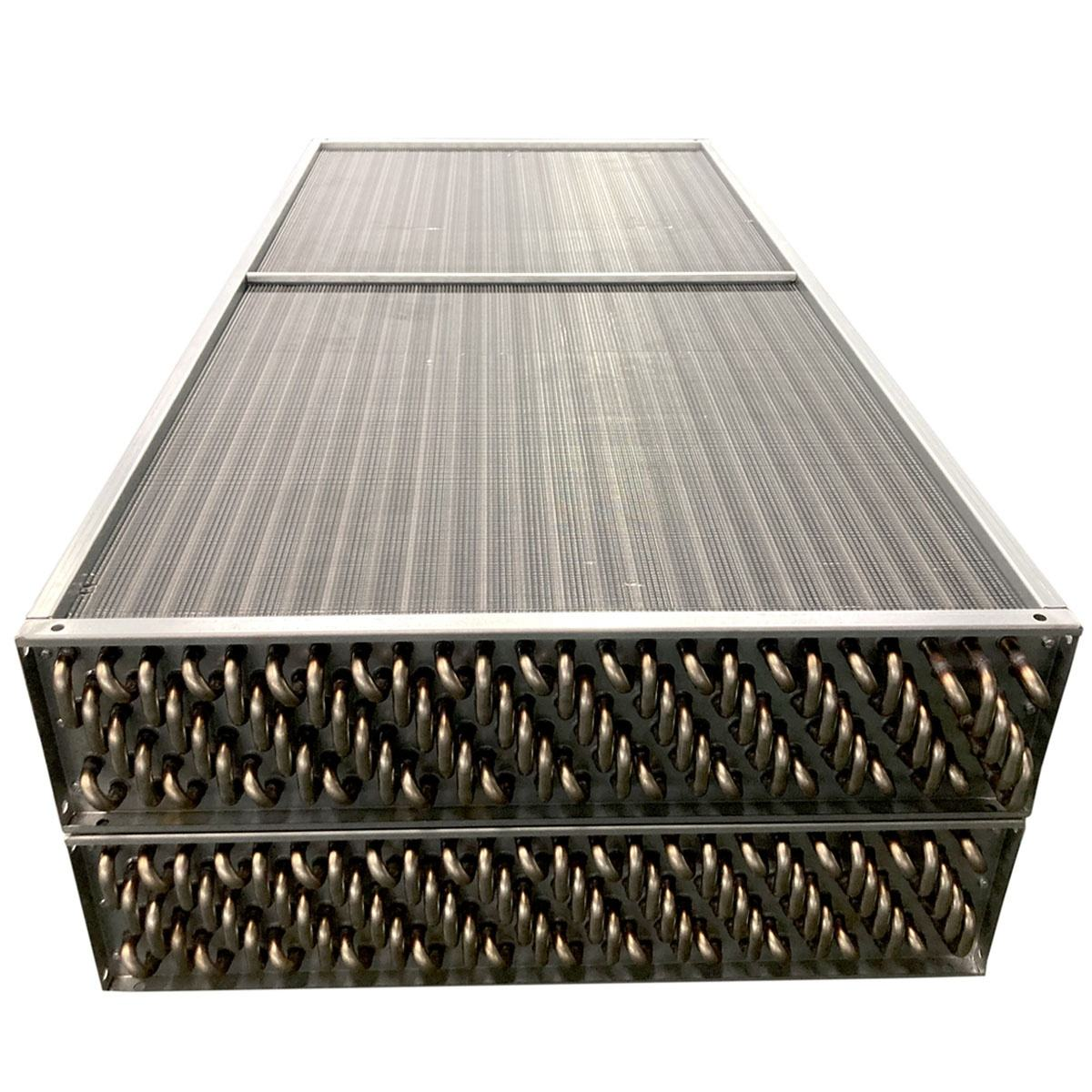

Understanding the Core Heat Exchanger Design

The ingenuity of the shell and tube model lies in its straightforward yet powerful heat exchanger design. The apparatus consists of a large cylindrical vessel, known as the shell, which encloses a bundle of tubes. During operation, one fluid is directed to flow through these small-diameter tubes, while a second fluid circulates within the shell and flows over the exterior of the tube bundle. Heat is then conducted through the tube walls, moving from the hotter fluid to the cooler one. To enhance this process and maximize thermal transfer, baffles are often placed within the shell to direct the flow of the shell-side fluid across the tube bundle, creating turbulence and increasing the heat transfer coefficient. This meticulous engineering ensures that energy is exchanged efficiently and predictably.

Why Shell and Tube Exchangers are Premier Thermal Transfer Solutions

These devices are widely regarded as premier thermal transfer solutions due to their remarkable versatility and durability. Constructed from high-grade materials like stainless steel, they are capable of withstanding extreme pressures and temperatures, making them ideal for heavy-duty applications. This resilience makes them a staple in demanding environments such as oil refineries, petrochemical processing facilities, and power generation plants. Their ability to handle both liquids and gases, as well as fluids with suspended solids, further broadens their utility. The robust construction minimizes maintenance requirements and ensures a long operational lifespan, providing a cost-effective solution for critical industrial heat exchangers that must perform reliably under continuous operation.

Maximizing Efficiency in Large Scale Heat Exchangers

When it comes to major industrial operations, the ability to scale equipment is crucial. The shell and tube design excels in this area, making it a go-to choice for large scale heat exchangers. Its modular nature allows for designs that can handle immense flow rates and significant thermal loads, essential for facilities like power stations and large chemical plants. The efficiency of these units is further optimized through specific design choices, such as the arrangement of fluid flow (e.g., counter-current flow for maximum temperature difference) and the selection of materials that offer excellent thermal conductivity and corrosion resistance. Features like standardized flanged connections simplify integration into existing pipelines, reducing installation time and facilitating smoother startups for complex systems.

Choosing the Right Industrial Heat Exchanger

In summary, the shell and tube heat exchanger remains a dominant technology in the field of thermal management for good reason. Its combination of a simple, effective design, robust construction, and unmatched scalability makes it a superior choice for a wide array of industrial applications. From processing chemicals to generating power, its reliability ensures that processes run smoothly and efficiently. As industries continue to evolve and demand greater performance, the foundational principles and adaptability of the shell and tube heat exchanger ensure it will continue to be a vital component for effective and dependable temperature control.