Understanding Plate Heat Exchanger Gasket Issues

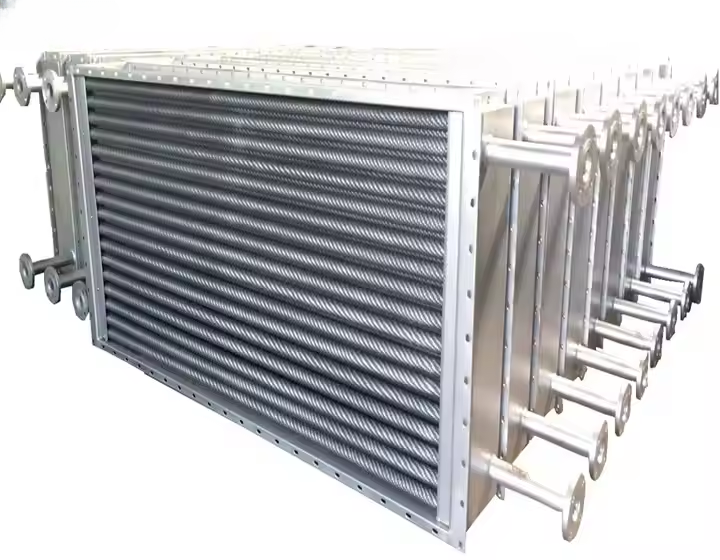

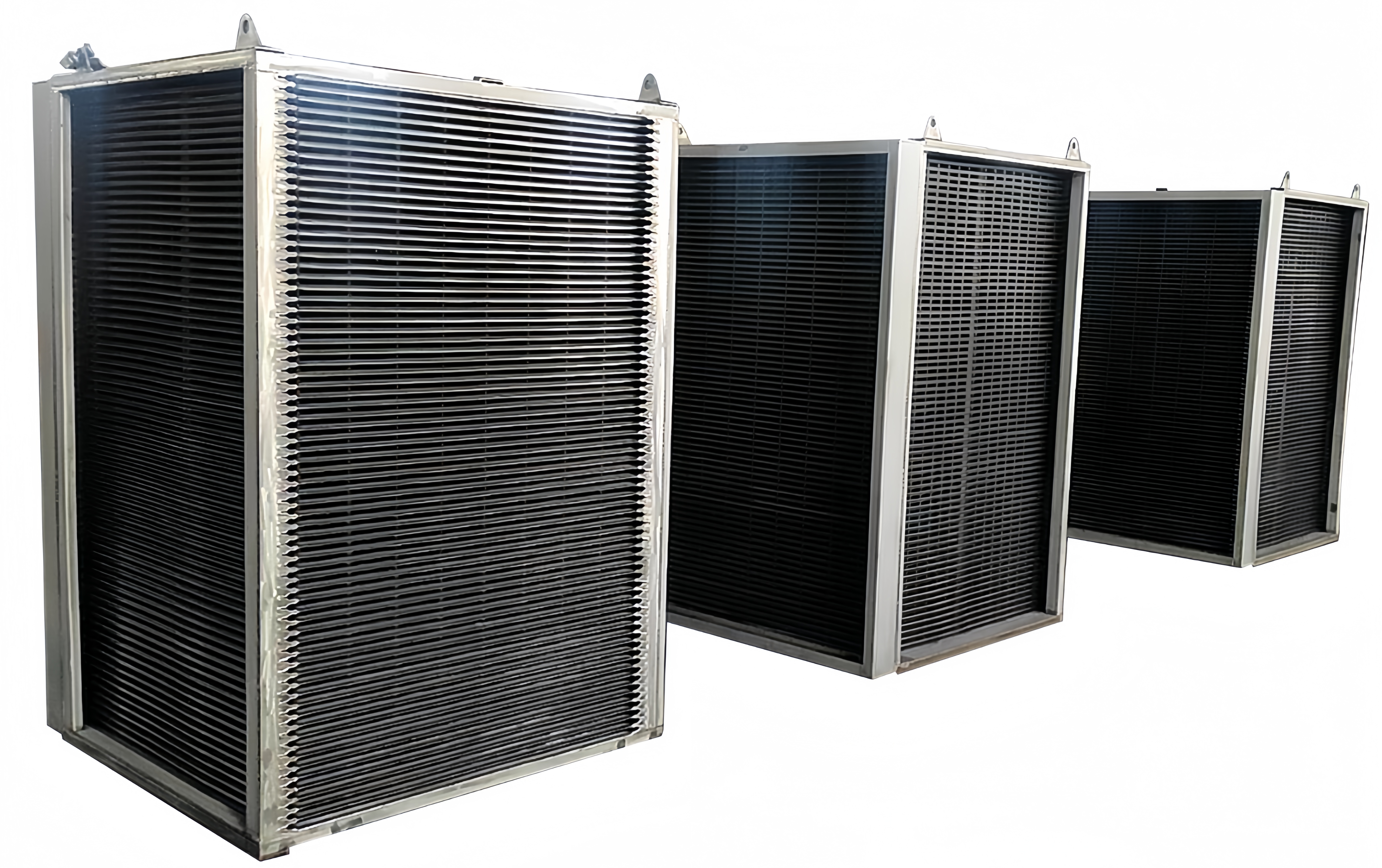

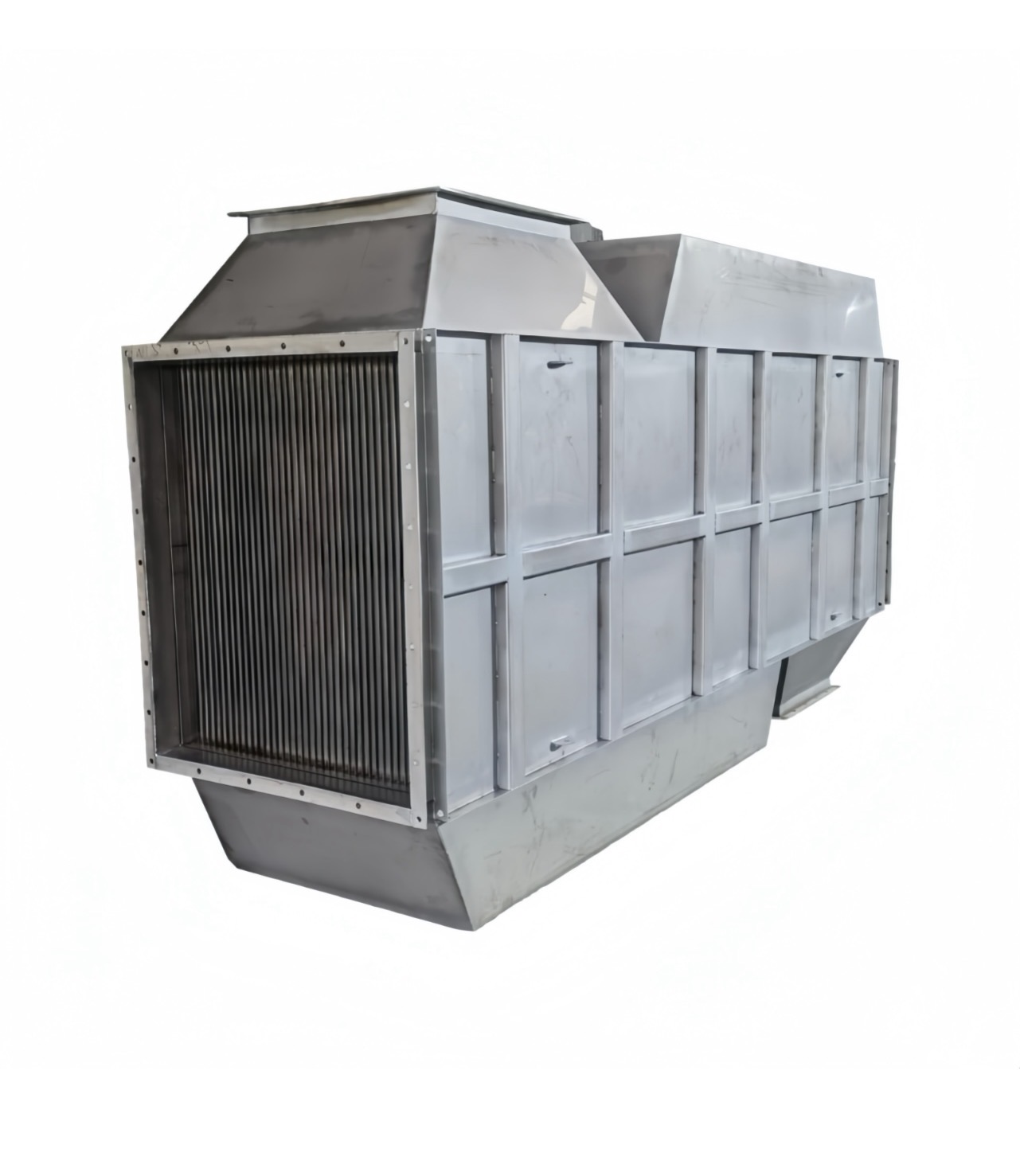

Plate heat exchangers are a pivotal component in numerous industrial sectors, providing energy efficiency and temperature control in operations such as HVAC, petrochemicals, and industrial manufacturing. However, over time, plate heat exchanger gasket issues can arise, potentially leading to reduced performance, leaks, or even failures if not addressed promptly. Understanding these challenges and knowing how to tackle them is essential to maintain seamless workflow and minimize downtime.

One of the most common problems faced by industries is gasket wear and tear. This issue can be caused by prolonged exposure to extreme temperatures, aggressive chemicals, or mechanical stress. The symptoms of a failing gasket can include irregular leaks, reduced thermal efficiency, and noise stemming from misaligned components. Diagnosing gasket leaks early on can prevent further damage and help you proactively address underlying causes.

Troubleshooting Gasket Leaks and Common Problems

Troubleshooting heat exchanger gaskets starts with an effective visual inspection. Look for signs of deformation, brittleness, or cracks on the gasket material. These are common gasket problems that can compromise sealing efficiency. Additionally, fouling and clogging can occur on the gasket surfaces, reducing heat transfer effectiveness and causing operational inefficiencies.

Gasket leak troubleshooting should include ensuring proper alignment and torque distribution across the plates. Misaligned plates can lead to uneven pressure on gaskets, while over/under-tightening bolts can exacerbate leaks. Opting for gasket sealing solutions that adhere to manufacturer specifications helps mitigate such problems and ensures consistent performance.

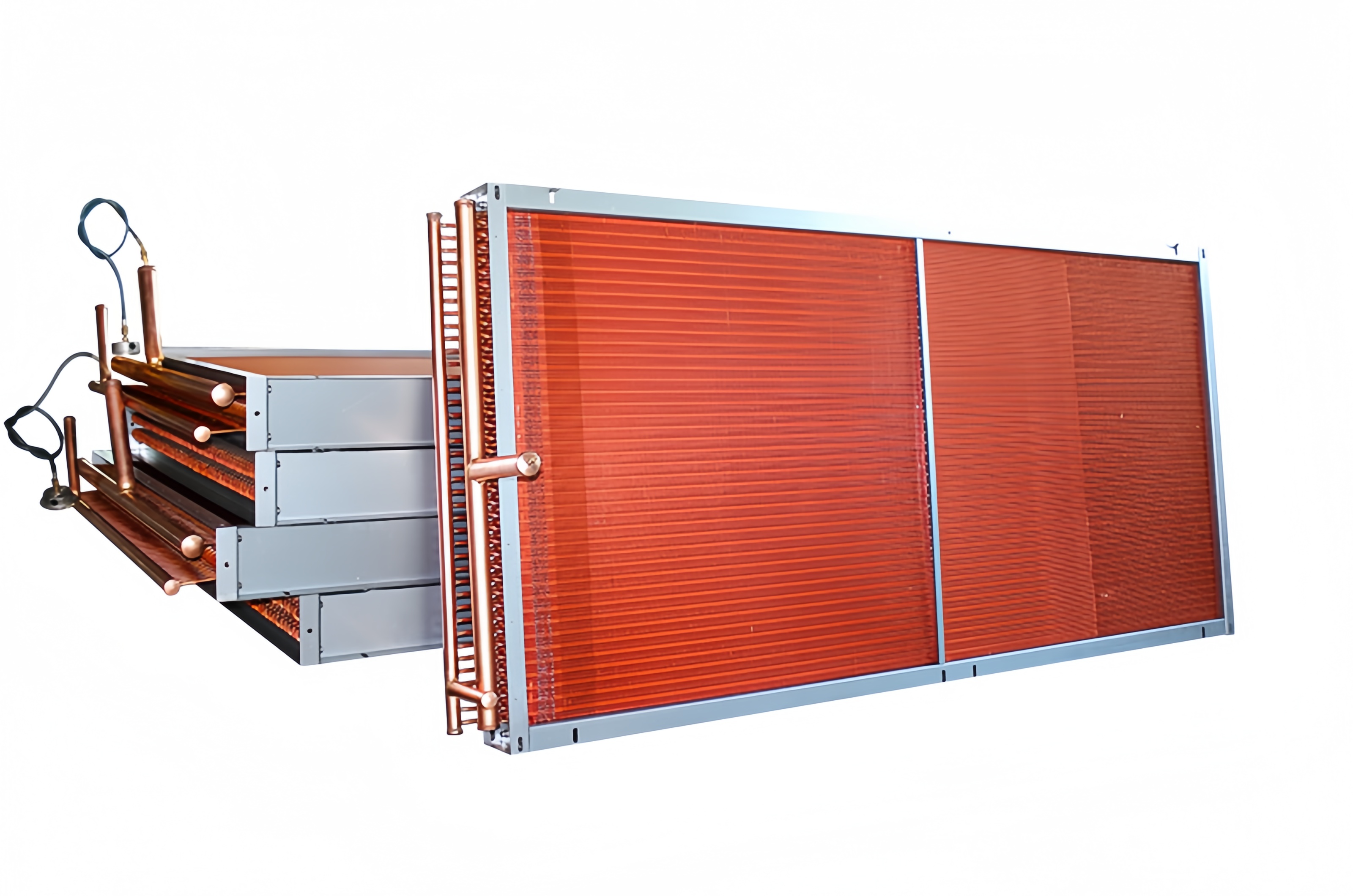

For industries dealing with frequent replacements, selecting a reliable and durable gasket is crucial. High-performance plate heat exchanger gaskets, such as the ones specially designed for industrial use, are built to withstand these challenges. Crafted with advanced materials, they resist chemical aggression, maintain elasticity, and guarantee precision-matching for major exchanger models, making troubleshooting and replacements quicker and easier.

Benefits of High-Performance Gasket Replacement

Heat exchanger gasket replacement doesn't have to be daunting. With the right product, you can enhance efficiency, prevent leaks, and reduce energy consumption. Investing in gaskets like **High-Performance Plate Heat Exchanger Gaskets** ensures your operations stay ahead of potential issues while lowering downtime.

These gaskets offer features like enhanced resilience to temperature extremes and chemical exposure. Their smooth, non-porous surfaces fight contaminant buildup, reducing clogging and maintaining flow rates. Furthermore, unique markings on these gaskets simplify problem identification and assist in a seamless replacement process.

Reliable gaskets not only secure industrial processes but also promote energy efficiency. By maximizing heat recovery and improving thermal precision, they contribute to sustainability goals, a key aspect in modern industrial practices. Companies can also benefit from quick troubleshooting, as these gaskets allow visual inspections without the need for advanced tools or extended system shutdowns.

Conclusion

Managing plate heat exchanger maintenance involves addressing gasket wear and tear effectively. From diagnosing gasket leaks to implementing efficient gasket sealing solutions, ensuring the reliability of your heat exchanger starts with high-quality components. Opt for a product like **High-Performance Plate Heat Exchanger Gaskets**, purpose-built for industrial versatility and designed to tackle common gasket problems.

These gaskets help industries optimize energy use, enhance performance, and reduce maintenance costs—delivering a dependable solution that fits your system's demands. Whether you're navigating challenging petrochemical processes or ensuring smooth HVAC operations, make a choice that not only solves problems but elevates your system's efficiency and durability.