The Growing Challenge of Industrial Energy Management

Modern industries face escalating challenges in managing their energy consumption effectively. Volatile energy prices, peak demand charges, and the increasing pressure to adopt sustainable practices are compelling businesses to seek innovative solutions. One of the most promising approaches to address these issues is through the implementation of advanced thermal storage. These systems are a key part of broader energy storage solutions, offering a way to decouple energy generation from its consumption, thereby enhancing operational flexibility and reducing costs. Effective thermal management is paramount.

Understanding Thermal Energy Storage

So, what exactly is this process of retaining heat? At its core, thermal energy storage (TES) involves capturing and holding thermal energy – either heat or cold – for subsequent use. This energy can be sourced from renewables, waste heat, or off-peak electricity. When demand arises, the stored energy is discharged. Benefits include reduced bills, improved efficiency, and a smaller carbon footprint. There are several thermal storage technologies available, from sensible heat methods to latent heat approaches. Utilizing an effective mechanism for retaining heat is key.

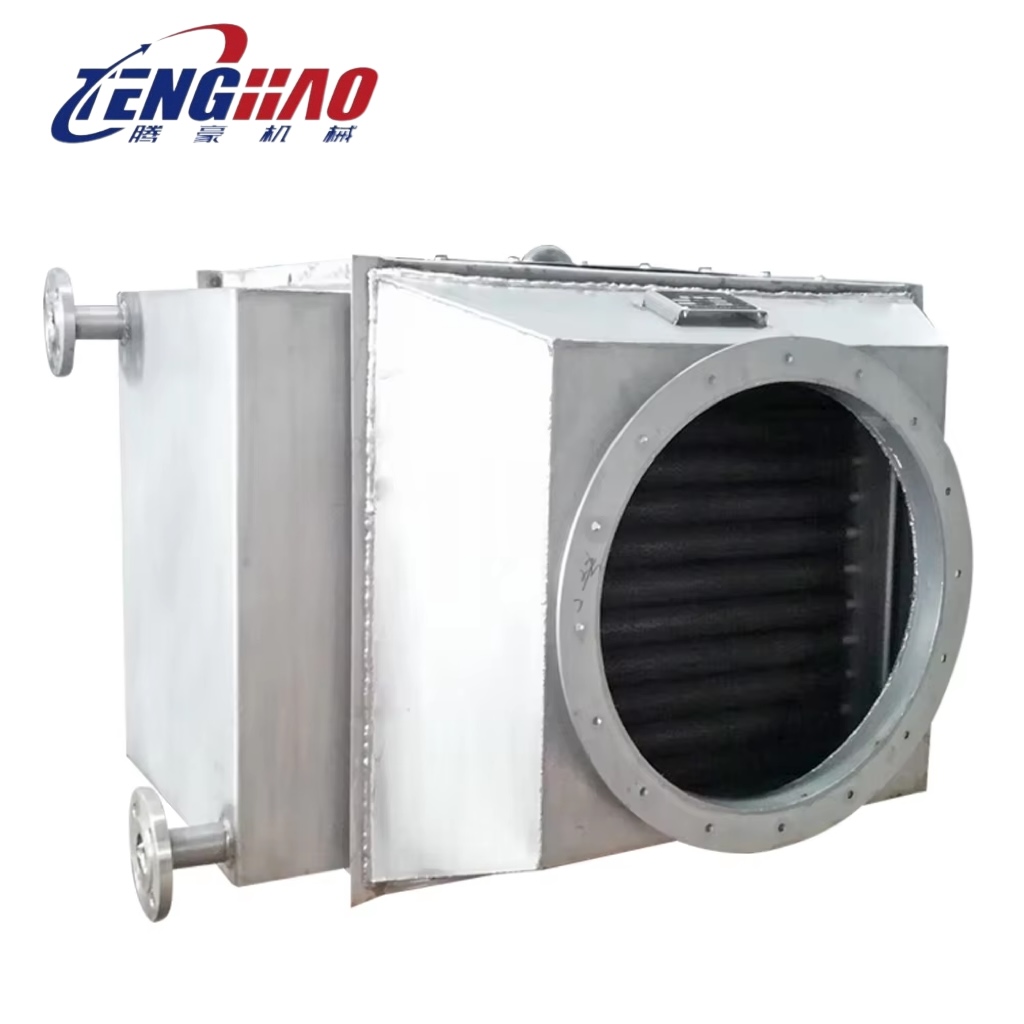

The Indispensable Role of Heat Exchanger Systems

For any system designed to retain heat to operate efficiently, effective energy transfer is crucial. This is where heat exchanger systems play an indispensable role. A heat exchanger facilitates the transfer of thermal energy between fluids at different temperatures without mixing. In this context, a robust heat exchanger ensures that energy can be charged into the storage unit rapidly and discharged just as quickly. The design of the heat exchanger directly impacts performance. For demanding industrial applications, specialized industrial heat exchangers are often required.

Harnessing Waste Heat: The Power of Heat Recovery Systems

Beyond storing intentionally generated heat, industries can unlock significant savings by implementing heat recovery systems. Many processes generate waste heat. These heat recovery systems capture this lost energy for repurposing. Often, these recovery methods work in conjunction with facilities for thermal storage. For example, recovered waste heat can be held until needed. Integrating heat recovery systems reduces primary energy consumption and lowers costs.

Ensuring Durability and Safety in Thermal Implementations

The long-term viability of any installation meant for energy retention hinges on component quality. Effective systems, particularly those under demanding conditions, rely on robust infrastructure, often including high-quality pressure vessels. These must handle fluctuating loads and pressures safely. For instance, vessels crafted from high-grade stainless steel are essential for the integrity of many relevant types of thermal storage technologies. Component reliability is fundamental to the success of industrial energy storage solutions and ensuring safety. This is where quality engineering, for example in advanced pressure vessel designs that allow for stable operations and feature precision welding for secure containment, becomes paramount.

The Future of Sustainable Industrial Operations

As industries globally move towards sustainability, smart energy management is essential. Utilizing thermal storage, alongside advanced heat exchanger systems and comprehensive methods for reclaiming heat, is at the forefront. These approaches collectively offer powerful ways to optimize energy use and cut environmental impact. By intelligently managing thermal resources, industries achieve cost savings and enhance resilience. Continuous innovation in thermal energy storage and associated components promises even more efficient systems.