The Crucial Role of Evaporators in Modern Cooling

The evaporator for refrigeration stands as a cornerstone in any cooling cycle, whether it's for preserving food, maintaining comfortable indoor climates, or supporting industrial processes. Its fundamental task is to absorb heat from the space or product to be cooled, facilitating the phase change of refrigerant from a liquid to a gas. While the principle is universal, the design, scale, and specific characteristics of evaporators vary significantly, leading to a diverse landscape of units tailored for distinct applications and performance requirements. Understanding these differences is key to selecting the right component for optimal efficiency and effectiveness.

Commercial vs. Industrial Evaporators: Tailoring to Scale and Demand

When comparing evaporator units, a primary distinction lies between those designed for commercial and industrial applications. Commercial evaporator units are commonly found in supermarkets, restaurants, and walk-in coolers. These units prioritize a balance of performance, space efficiency, and relatively straightforward maintenance. They need to handle frequent door openings and varying loads. In contrast, an industrial refrigeration evaporator is built for much larger capacities and more demanding environments, such as large-scale cold storage warehouses, food processing plants, and chemical facilities. Industrial units often feature more robust construction, higher airflow rates, and are designed for continuous, heavy-duty operation. While a commercial unit might focus on rapid pull-down times for smaller volumes, an industrial counterpart emphasizes sustained low temperatures for vast spaces and significant product loads. The design considerations will therefore differ in terms of material thickness, fan power, and overall structural integrity.

Evaporators in Comfort Cooling: Air Conditioning and Chiller Applications

The function of an air conditioning evaporator coil, while similar in principle to refrigeration units, operates under different conditions and priorities. AC evaporators are designed to cool air to comfortable temperatures, typically above freezing, and play a significant role in dehumidification. They operate with higher evaporating temperatures compared to refrigeration systems. Evaporator coils for chillers, on the other hand, are often part of larger systems that cool water or a brine solution, which then circulates to provide cooling elsewhere, such as for large buildings or industrial processes. These chiller evaporators can be shell-and-tube, plate, or brazed plate heat exchangers, and their design focuses on efficient heat transfer to the secondary liquid. While both AC and chiller evaporators are crucial for their respective systems, they differ from direct expansion refrigeration evaporators in their target medium and operating temperature ranges.

Diverse Designs and Material Innovations in Refrigeration Evaporators

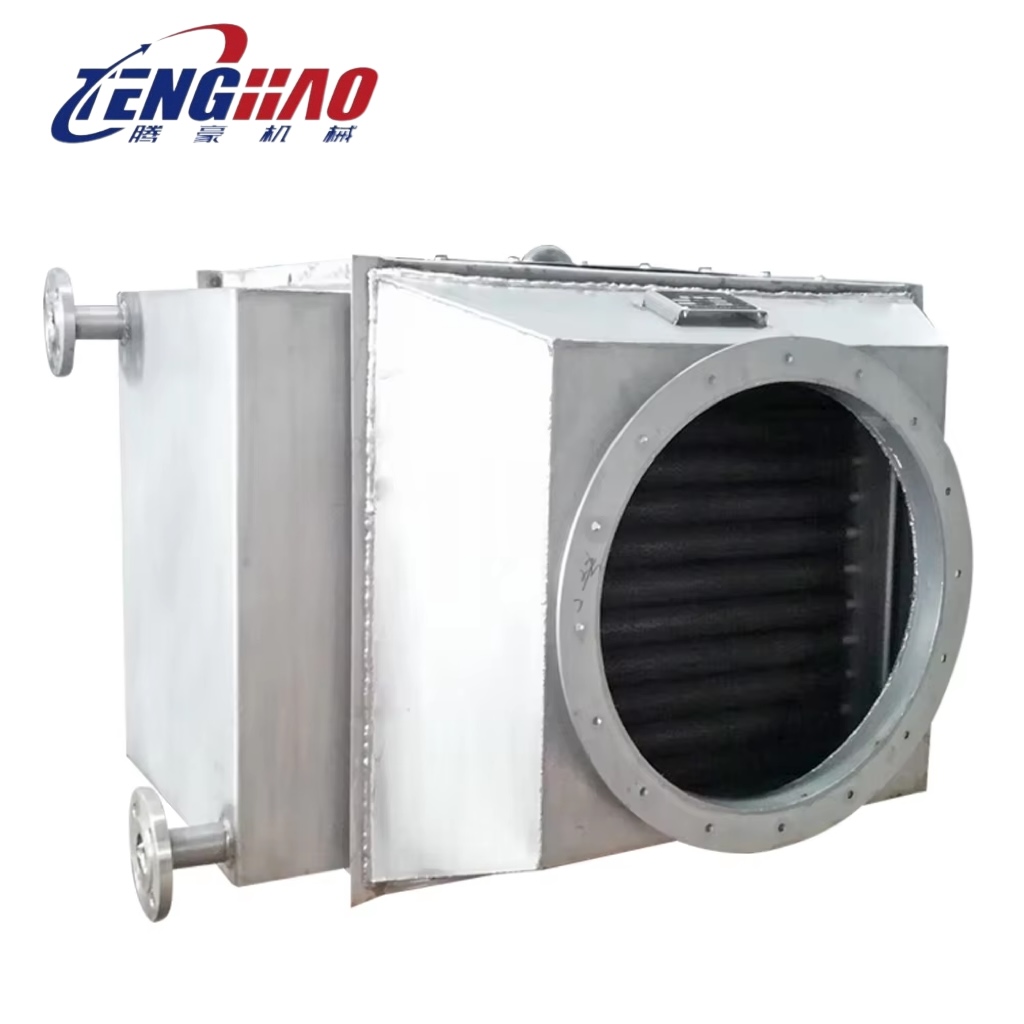

The world of refrigeration evaporator types is vast, with refrigeration evaporator design evolving continuously to enhance efficiency and sustainability. Finned tube evaporators are highly common, where refrigerant flows through tubes and heat is absorbed from air passing over external fins. The materials used are critical; for instance, the Tenghao Refrigeration Evaporator utilizes premium copper tubes for their high thermal conductivity and corrosion resistance, surrounded by aluminum fins that dramatically increase the surface area for superior heat dispersion. This specific design enhances the heat absorption vital for the refrigeration system evaporator. Furthermore, many modern designs, including Tenghao's, leverage forced convection, potentially incorporating fan systems to expedite heat transfer, a significant step up from older natural convection models. Advanced defrosting solutions, like integrated electric defrost systems with smart controls, are also becoming standard to maintain efficiency by preventing frost build-up, a feature highlighted in advanced units.

Optimizing Performance: Heat Transfer, Efficiency, and Sustainability

Ultimately, the choice of an evaporator boils down to its performance and overall efficiency. Key metrics include heat transfer rates and the Coefficient of Performance (COP). An effectively designed evaporator, like the Tenghao model which boasts impressive heat transfer rates, ensures rapid cooling and precise temperature control. A high COP, also a feature of well-engineered units, indicates superior energy efficiency, translating to lower operational costs and a reduced environmental footprint. The compatibility with eco-friendly refrigerants, such as R-290 or R-448A, is another crucial aspect, reflecting a commitment to sustainability. When comparing different evaporators, it's essential to look beyond initial cost and consider these performance indicators, the quality of materials, and the sophistication of its design features, as these factors will significantly impact long-term reliability and operational economy in any refrigeration application.