The Pinnacle of Modern Thermal Management

In the world of industrial processing, effective thermal regulation is not just a necessity; it's the backbone of efficiency, safety, and profitability. Central to this is the stainless steel heat exchanger, a marvel of engineering designed to facilitate the transfer of heat between two or more fluids. This crucial piece of equipment is found across countless sectors, providing reliable performance and longevity. As industries evolve and demand more robust solutions, understanding the capabilities of advanced heat transfer equipment becomes paramount for maintaining a competitive edge and operational excellence.

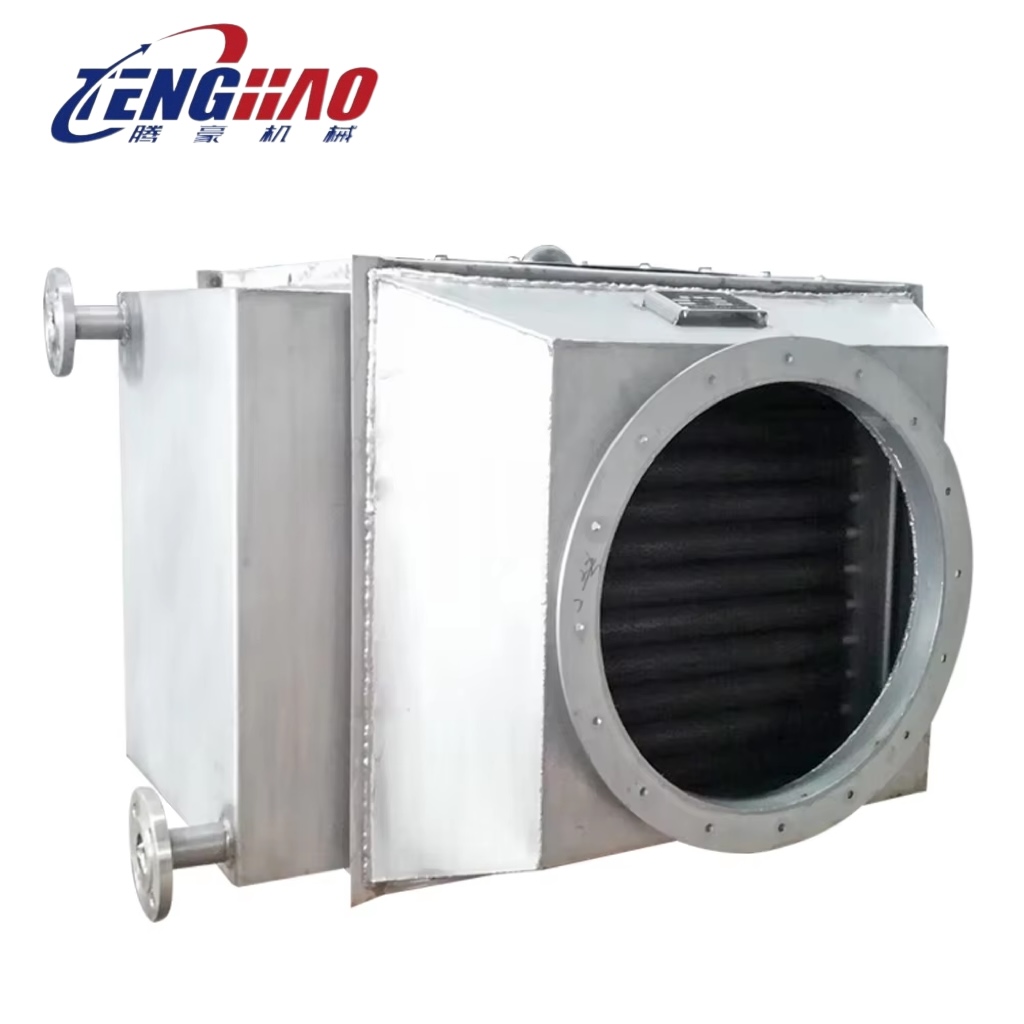

Engineered for Supreme Performance

At the heart of any high-functioning thermal system lies a powerful transfer mechanism. A modern stainless steel heat transfer unit is a perfect example of sophisticated design meeting practical application. These units come in various configurations to meet specific industrial needs. The shell and tube design, for instance, is renowned for its ruggedness and ability to handle high pressures and temperatures, making it ideal for the power generation and chemical industries. Alternatively, compact brazed plate models offer incredible efficiency in a smaller footprint, perfect for HVAC systems or applications where space is a premium. The goal of this anced stainless steel thermal transfer technology is to maximize surface area and optimize flow, ensuring rapid and effective heating or cooling with minimal energy loss. These designs are a testament to how intelligent engineering can solve complex thermal challenges.

Unmatched Durability and Material Advantage

One of the primary reasons for the widespread adoption of this technology is the material itself. Stainless steel offers a unique combination of strength, hygiene, and resistance to degradation. When it comes to corrosion-resistant heat exchangers, stainless steel is a top-tier choice, capable of withstanding harsh chemical environments and saline conditions without compromising structural integrity. This makes it invaluable for marine applications, chemical processing, and the food and beverage industry where cleanliness is non-negotiable. Furthermore, while the base thermal conductivity stainless steel might be lower than other metals, advanced designs with thin, embossed plates compensate for this, creating highly efficient transfer surfaces that are also easy to clean and maintain, promising a long and reliable service life.

Versatile Solutions for a Diverse Industrial Landscape

The adaptability of stainless steel industrial heat exchangers is one of their most significant assets. Their application is not limited to one or two sectors; they are integral components in a vast array of processes. In heavy industry, they are used in everything from metallurgical furnaces to chemical reactors, helping to control temperatures and enhance process efficiency. As stainless steel process equipment, they play a critical role in the pharmaceutical and food production sectors, ensuring product safety and quality. Beyond manufacturing, these units are pivotal in creating sustainable heat transfer solutions, supporting renewable energy systems like solar thermal plants and enabling waste heat recovery, which turns lost energy into a valuable resource. From large-scale industrial complexes to sophisticated HVAC systems in urban buildings, their presence drives efficiency and sustainability.

The Future of Efficient Energy Transfer

Ultimately, a state-of-the-art stainless steel heat exchanger represents more than just a component; it is a comprehensive solution for modern thermal management. It promises and delivers efficiency, reliability, and forward-thinking design. Customization allows these units to be tailored to specific operational needs, whether that involves managing extreme temperatures, accommodating high flow rates, or fitting into a unique physical footprint. By integrating this advanced technology, industries can significantly reduce energy consumption, lower operational costs, and improve their environmental footprint. Trusting in the resilience and proven performance of stainless steel is an investment in a more efficient, productive, and sustainable future.