In today's energy-conscious world, industries are constantly seeking innovative ways to enhance efficiency and reduce operational costs. Among the forefront of these technologies are plate heat exchangers, representing a significant leap forward in thermal management. When you're looking for truly high efficiency heat exchangers, these sophisticated devices offer unparalleled performance, compact design, and remarkable adaptability, making them an indispensable component in a wide array of applications. Choosing them is not just an operational upgrade; it's a strategic decision towards sustainability and economic prudence.

Unveiling the Ingenuity: How Plate Heat Exchangers Excel

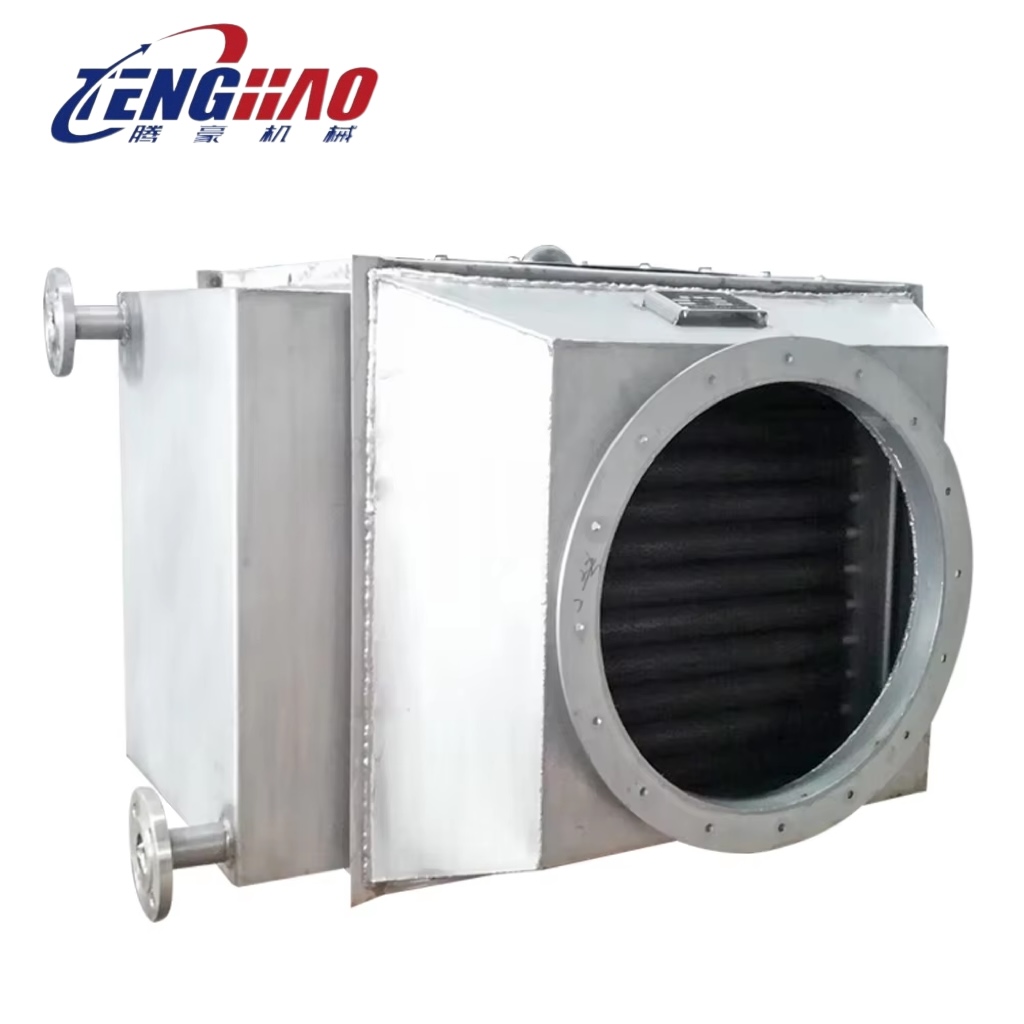

But what makes plate heat exchangers so effective? Their genius lies in their deceptively simple design. Comprising a series of thin, corrugated metal plates, these units create intricate channels for fluid flow. Hot and cold fluids pass through alternate channels, facilitating heat transfer across the large surface area of the plates without mixing. The corrugations induce turbulence, even at low flow rates, which significantly enhances the heat transfer coefficient compared to traditional shell-and-tube exchangers. This design not only maximizes thermal exchange but also contributes to a compact footprint, a crucial advantage in space-constrained industrial environments. This inherent efficiency is why they are often at the core of modern industrial heat exchange solutions.

Maximizing Efficiency, Minimizing Waste: The Energy Advantage

The drive for greater energy efficiency is a paramount concern across all sectors, and this is where energy efficient plate heat exchangers truly shine. Their ability to achieve very close temperature approaches – meaning the outlet temperature of the heated fluid can be very close to the inlet temperature of the heating fluid – translates directly into reduced energy consumption. Less energy is wasted, leading to lower fuel bills and a smaller carbon footprint. For companies striving for optimal thermal management solutions industrial settings, adopting these exchangers is a clear path to achieving both economic and environmental goals. The precision in heat recovery offered by plate heat exchangers makes them an indispensable asset for sustainable operations, ensuring that every unit of energy is utilized to its fullest potential.

The Go-To Choice: Plate Heat Exchangers Across Industries

The versatility of plate heat exchangers is another compelling reason for their widespread adoption. You'll find these robust units performing critical tasks in a multitude of industries. From HVAC systems ensuring comfortable building environments and food and beverage processing requiring precise temperature control for pasteurization and sterilization, to demanding chemical processing applications and power generation plants needing efficient cooling, they prove their worth. The marine industry also heavily relies on them for engine cooling and onboard thermal regulation. Their adaptability to various fluids, temperatures, and pressures makes them a cornerstone of various industrial heat exchange solutions, demonstrating their capacity to meet diverse operational demands effectively and reliably, further solidifying their reputation as high efficiency heat exchangers.

Tailored to Perfection: The Rise of Custom Plate Heat Exchangers

While standard models cater to many needs, the true potential of this technology is often unlocked through customization. Opting for custom plate heat exchangers allows for designs that are precisely engineered to meet specific operational parameters, fluid characteristics, and space constraints. This bespoke approach ensures optimal performance, maximum efficiency, and longevity for unique applications where off-the-shelf solutions might fall short. Whether it's selecting specialized plate materials for corrosive fluids, configuring unique flow patterns for challenging thermal duties, or designing for extreme temperatures and pressures, custom plate heat exchangers provide a tailored fit that significantly enhances system reliability and operational output. This focus on specific needs elevates general thermal management solutions industrial to a new level of precision.

Make the Smart Switch: Embrace Advanced Heat Exchange Technology

In conclusion, the argument for adopting advanced heat exchange technology is overwhelmingly strong, and plate heat exchangers stand at the forefront of this revolution. Their superior thermal performance, compact size, energy-saving capabilities, and adaptability across numerous industries make them an intelligent investment. By choosing these systems, particularly energy efficient plate heat exchangers or specialized custom plate heat exchangers, businesses are not merely upgrading equipment; they are embracing a future of enhanced productivity, reduced environmental impact, and significant long-term cost savings. It's time to move beyond outdated methods and leverage the power and sophistication that modern heat exchange solutions offer. Consider the profound benefits for your operations and make the decisive switch to a smarter, more efficient thermal management strategy.