Understand Fin Tube Radiators: What are they?

The Finned Tube radiator revolutionizes the design and implementation of heat transfer systems due to its excellent efficiency and compact form. So, what is a fin tube radiator? This is a specialized heat transfer device that uses fin-equipped tubes to enhance surface area for heat exchange. These radiators are commonly used in HVAC systems and in a variety of industrial applications to ensure optimal thermal performance.

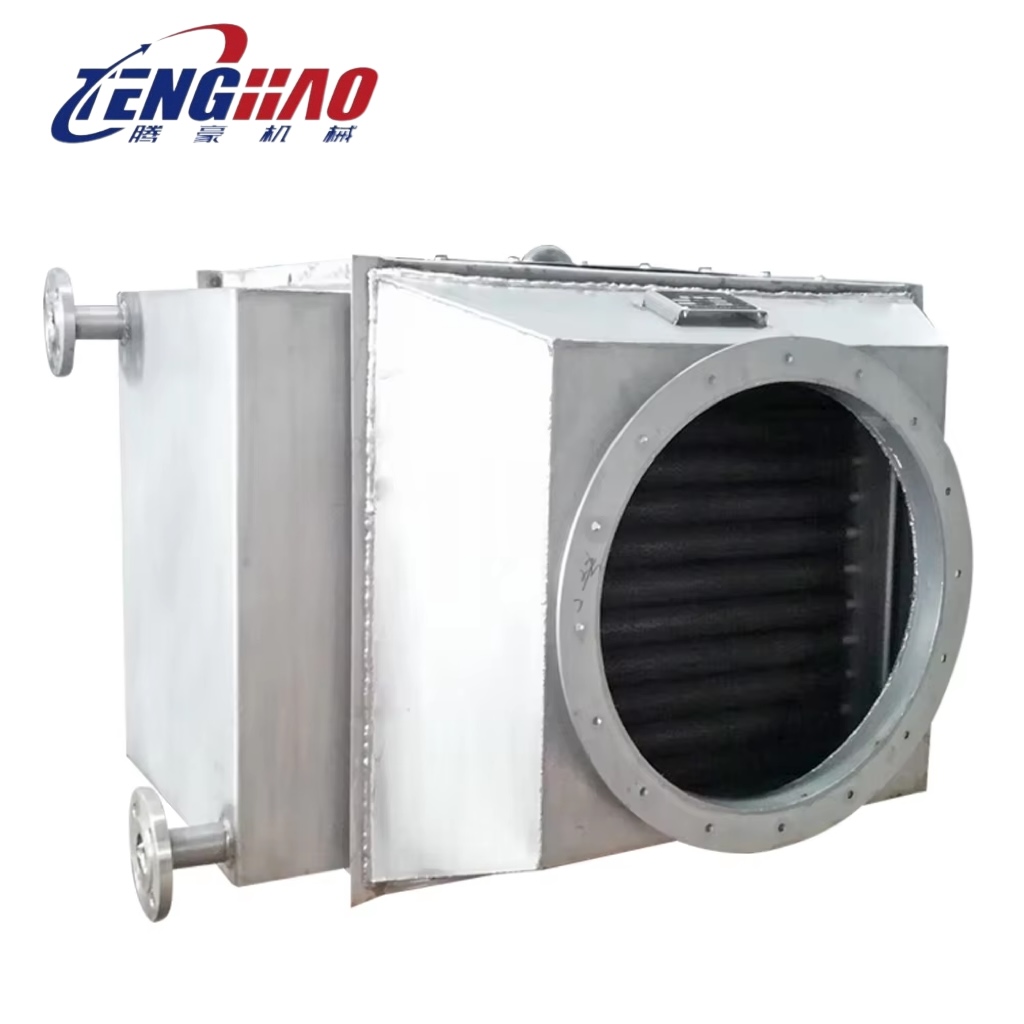

The innovative fin radiator design combines spiral fins connected to the tube to provide greater surface area for energy saving heat dissipation or absorption. This design is particularly beneficial in environments where reliable heating or cooling solutions, such as power plants, chemical reactors and refrigeration systems.

Application of Fin Tube Radiator

Due to their versatility and efficiency, fin tube radiators have been found in a wide range of industries. In HVAC systems, they serve as heat exchangers in condensers and evaporators, optimizing indoor temperature control with minimal energy consumption. Oil and gas refineries use fin’s pipe heating systems to maintain the required thermal levels during critical processes.

Industrial fin tube radiators are essential for power plants and they help regulate heat flow in turbines and boilers. In addition, these radiators play a key role in the refrigeration system to ensure a stable temperature of the food storage unit. The chemical processing industry often relies on fin tube heat exchangers to facilitate precise temperature control in reactors and pipelines.

The benefits of fin tube radiator

The benefits of fin tube radiators are huge, making it the preferred choice for residential and industrial applications. One of their main strengths is unparalleled energy efficiency. Fin tube radiator efficiency is derived from its ability to optimize heat transfer when using minimum energy, which greatly reduces operating costs.

Compatibility with various materials such as stainless steel, aluminum and copper ensures durability and resistance to corrosive environments or high pressure conditions. Compact and space-saving design allows industries with limited space to integrate these radiators without compromising thermal performance. In addition, the installation of the fin tube radiator is simple and can be seamlessly integrated into existing systems.

Why choose efficient fin tubes?

High efficiency fin tubes, described in advanced heat transfer technology, provide enhanced thermal performance due to their expanded surface area. These fin radiators are designed with high-quality materials such as stainless steel and copper to ensure long-term reliability and corrosion resistance. Customizable options for size, fin density and materials comply with a variety of industry standards including ASME, ASTM and ISO certification.

In addition, sustainable manufacturing practices make these fin tubes a green option for businesses working to reduce their carbon footprint. These radiators, such as embedded, extruded and welded fins, meet specific application needs, ensuring adaptability and efficiency.

Key Points

Fin tube radiators represent a leap in heat transfer technology, enabling the industry to achieve energy-saving and efficient systems. Whether you need a fin heating system for HVAC, refrigeration or high-pressure industrial applications, these radiators offer excellent performance as well as durability. Take the next step to optimize your thermal system by integrating the tip functionality of the fin tube radiator into your operation!