Why Consider HVAC Air Preheating?

In the quest for more sustainable and cost-effective building operations, HVAC air preheating emerges as a crucial strategy. This process involves warming up the incoming fresh air before it enters the main heating, ventilation, and air conditioning (HVAC) unit.

By doing so, it significantly reduces the workload on the primary heating system, leading to substantial energy savings and improved comfort levels. Understanding how to effectively implement this technique can make a marked difference in both residential and commercial environments, paving the way for smarter energy consumption.

How Do Air Preheating Systems Work?

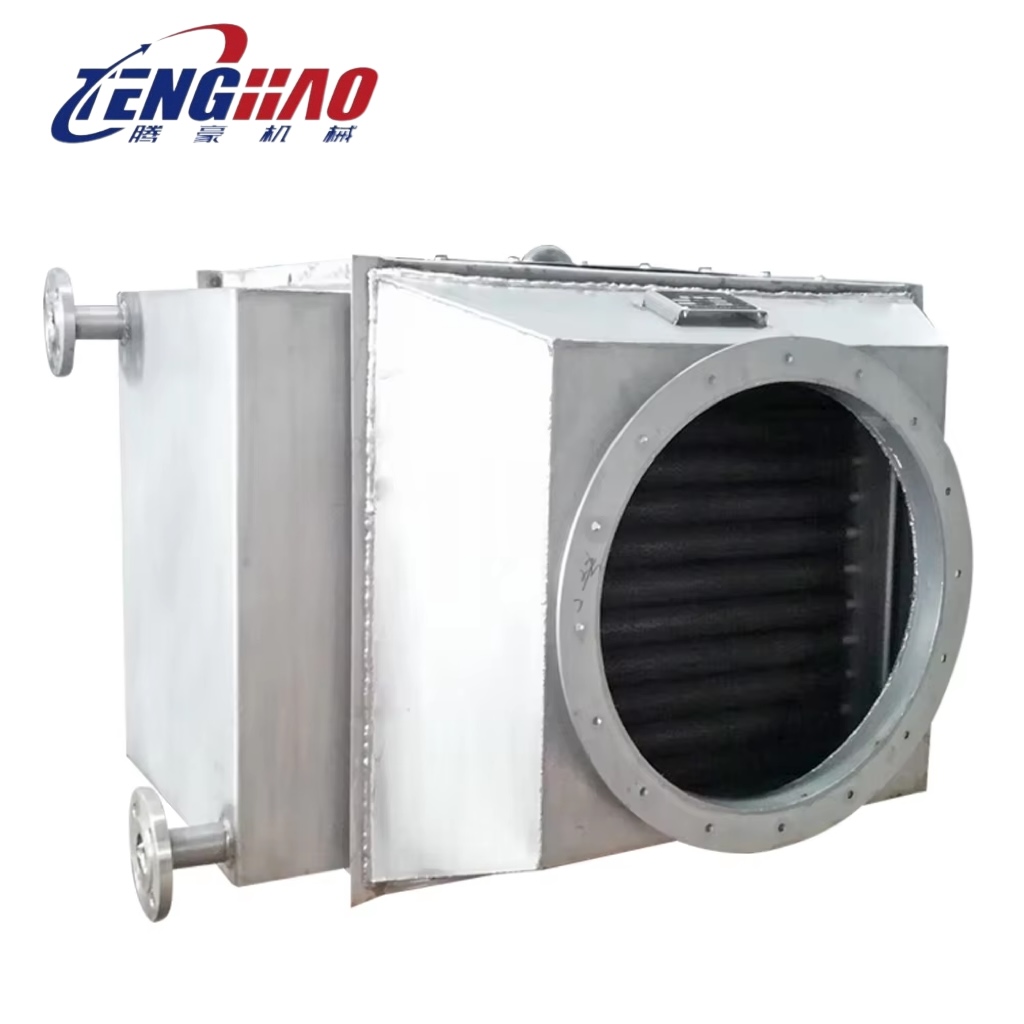

Air preheating systems operate on a simple yet effective principle: recovering and reusing heat that would otherwise be wasted. Typically, this involves an air-to-air heat exchanger.

As stale, warm air is exhausted from a building, its thermal energy is transferred to the incoming stream of cold, fresh air without the two air streams actually mixing. This pre-warmed fresh air then requires less energy to bring it to the desired indoor temperature.

Effective air preheating systems are vital for preheating air for HVAC units, especially in colder climates where the temperature difference between outdoor and indoor air is significant. Various designs exist, from rotary wheels to plate heat exchangers, each offering different efficiencies and suitability for specific applications. The core function remains the same: to elevate the temperature of intake air using recovered energy.

Key Benefits: Energy Efficiency and Cost Reduction

The primary advantage of incorporating an air preheating strategy is the significant boost in energy efficient heating. By reducing the temperature differential that the main HVAC system has to overcome, less fuel or electricity is consumed. This directly translates into lower utility bills and substantial HVAC energy savings over the lifespan of the system.

Beyond cost, improved air temperature control is another key benefit. Preheating ensures that the air entering the conditioned space is closer to the target temperature, minimizing cold drafts and improving overall occupant comfort.

Furthermore, reducing the load on the main HVAC unit can extend its operational life and reduce wear and tear, leading to lower maintenance costs. For commercial buildings, the impact of commercial air preheating can be particularly profound due to larger air volume requirements.

Considerations for HVAC System Design with Preheating

When planning an HVAC system design that includes air preheating, several factors must be considered. Firstly, the selection of the right heat exchanger is paramount. Look for units with high thermal transfer efficiency, durable construction, and excellent sealing to prevent air leakage, which can diminish performance.

Advanced inspection and sealing technology in such devices ensures superior air seal integrity, preventing airflow bypassing and efficiency loss. Strategic airflow management within the exchanger is also crucial, potentially incorporating features for integrated duct compatibility and ensuring correct flow direction.

It's important to correctly size the preheating unit based on the building's ventilation needs and typical climate conditions. Furthermore, the system should allow for precision monitoring of temperature and pressure, perhaps with capabilities for real-time data logging and alerts for abnormal conditions.

Proper integration with the existing or new ductwork, along with controls that can manage the preheating process effectively, will maximize the benefits of HVAC air preheating. Gradual start-up capabilities can also minimize potential damage from pressure surges and facilitate smooth air stabilization.

Steps to Implement and Optimize Air Preheating

Implementing an air preheating solution involves several practical steps. First, assess your current HVAC setup and ventilation requirements to determine if preheating is a viable and beneficial upgrade. This might involve an energy audit to quantify potential HVAC energy savings.

Next, research and select a suitable air-to-air heat exchanger. Focus on models that promise high efficiency, robust construction, and ease of maintenance. Features like easy access for cleaning, intuitive parts exchange, and resilient sealing mechanisms are important for long-term, contamination-free operation.

Installation should be carried out by qualified professionals to ensure correct duct connections, proper sealing, and integration with the HVAC controls for optimal preheating air for HVAC.

Once installed, regular maintenance is key. This includes cleaning the heat exchanger surfaces to maintain thermal efficiency and checking seals and gaskets to prevent air leakage. Regularly monitor the system’s performance to ensure it’s delivering the expected HVAC energy savings and maintaining effective air temperature control. This continuous optimization will ensure your investment in an air preheating system pays off.

Embracing a More Efficient Future with Air Preheating

Adopting HVAC air preheating is a smart move for anyone looking to enhance their building's energy performance and reduce operational costs. By intelligently recovering and reusing heat, these systems significantly lessen the burden on primary heating units, promoting energy efficient heating and comfort.

Whether designing a new HVAC system design or upgrading an existing one, incorporating strategies for preheating air for HVAC offers a clear path towards greater sustainability and efficiency. The initial investment is often quickly recouped through sustained energy savings, making it a valuable addition for both residential comfort and the demands of commercial air preheating applications.