Revolutionizing Industrial Efficiency with High-Efficiency Heat Exchangers

In the rapidly advancing industrial sector, optimizing thermal efficiency is pivotal, making the adoption of high-efficiency heat exchangers essential. These advanced components are integral to modern power stations, as vividly depicted in images of contemporary industrial facilities equipped with these cutting-edge devices.

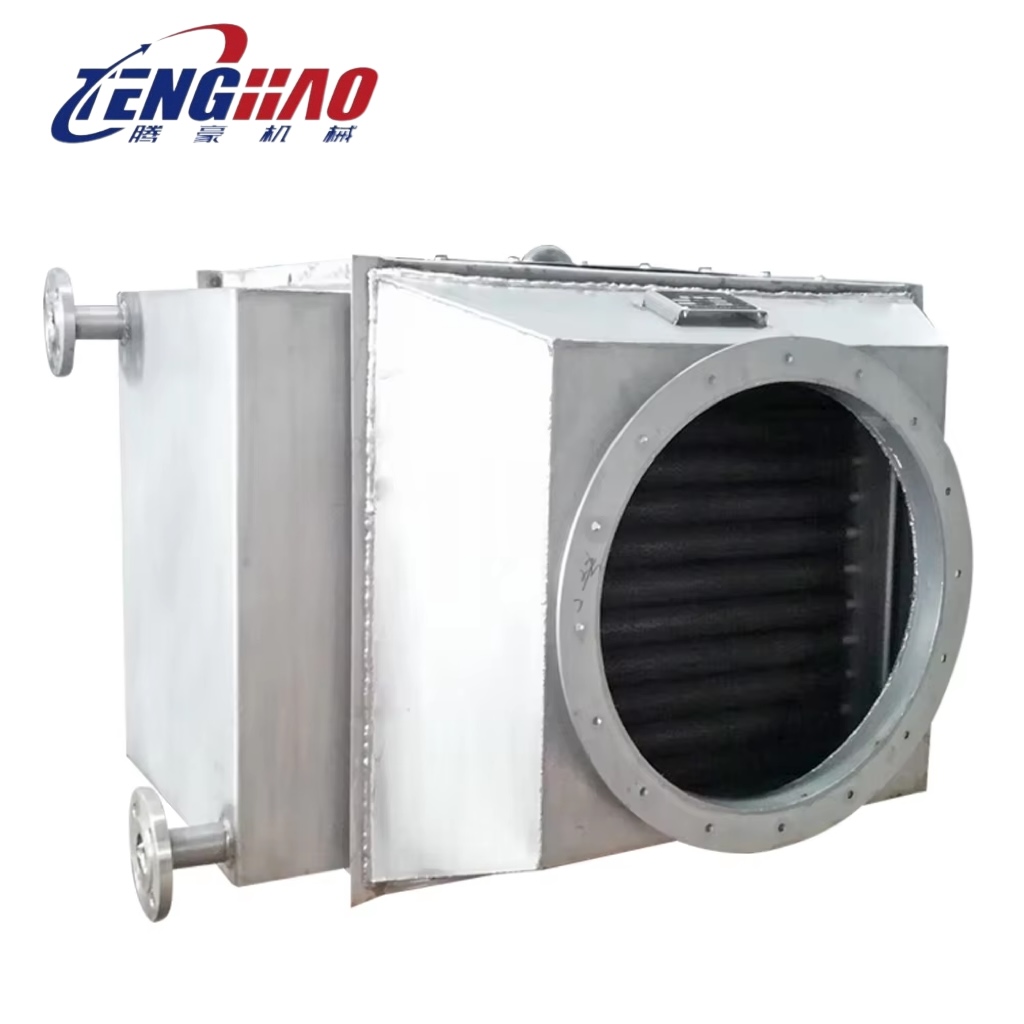

Unveiling the Spiral Design Heat Exchangers

Introducing the spiral heat exchangers, a breakthrough in energy recovery technology tailored for today's evolving industrial requirements. Utilizing a unique spiral plate geometry, these exchangers enhance efficient heat transfer and drastically cut operational costs. Their design uniquely facilitates self-cleaning action in turbulent flow conditions, minimizing fouling more effectively compared to conventional designs. This feature not only prolongs the equipment's lifespan but also ensures consistently high performance, crucial for industries relying heavily on efficient heat transfer.

Advantages of Compact Heat Exchanger Design

One of the standout features of these spiral heat exchangers is their compact heat exchanger design, requiring significantly less space—30-50% less than traditional systems—making them ideal for retrofitting projects or installations where space is limited. Moreover, built from corrosion-resistant materials, these exchangers are capable of handling tough environments, be it acidic, alkaline, or marine conditions.

Enhancing Sustainability in Power Generation

Industries such as power generation see immense benefits, particularly in flue gas condensation processes. Here, the spiral heat exchangers boost boiler efficiency through heat recovery. Featuring energy-saving heat exchanger technology, they capture residual heat and condense vapors to reclaim latent heat, striking a balance between operational efficiency and sustainability.

Versatility and Future-Ready Solutions

The versatility of these high-efficiency heat exchangers is extraordinary. Whether it's capturing waste heat in industrial settings at temperatures as low as 50°C or ensuring sanitary conditions in the food and beverage industry, they adapt seamlessly. Committed to future-ready solutions, these exchangers are equipped to integrate IoT-enabled sensors for real-time monitoring, paving the way for intelligent thermal management solutions. Conclusively, the high-efficiency spiral heat exchangers symbolize the leap towards innovative thermal management solutions, setting facilities on a path to success and ecological responsibility.