In the world of industrial processing and energy production, efficient heat management is paramount. Optimizing how heat is transferred not only reduces operational costs but also enhances overall system performance and longevity. This guide delves into the specifics of one of the most effective components in modern thermal systems: Spiral Fin Tubes. These specialized tubes are engineered to maximize heat transfer efficiency, making them a cornerstone in various demanding applications.

Understanding the Design of Spiral Fin Tubes

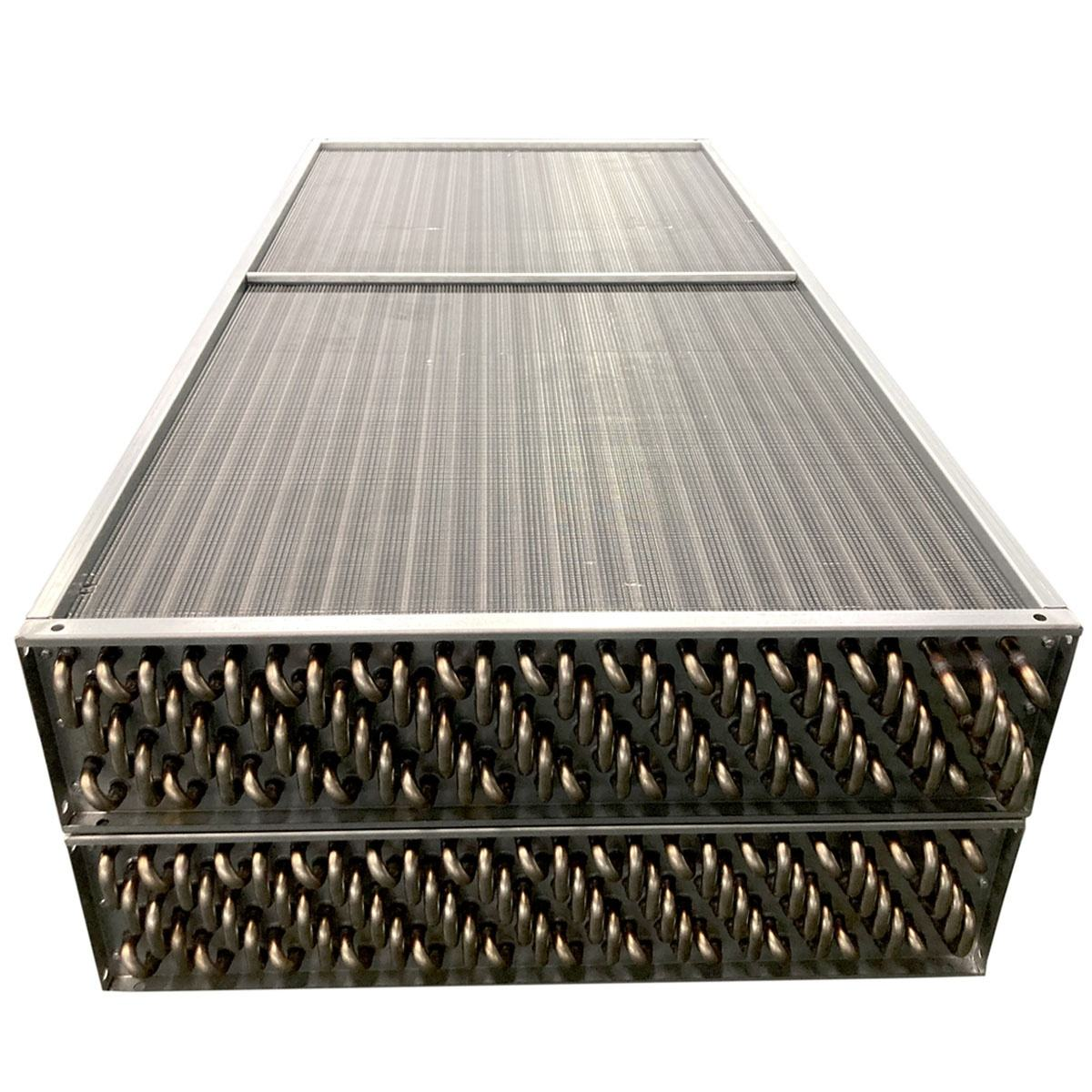

At their core, these components are a type of advanced Heat Exchange Tubes. They consist of a solid base tube over which a continuous strip of metal, the fin, is helically wound and securely attached. This construction drastically increases the external surface area of the tube compared to a plain, smooth tube of the same diameter. The choice of materials for both the tube and the fin is critical, often involving robust alloys that can withstand high temperatures, pressures, and corrosive environments, resulting in truly Durable Spiral Fin Tubes. The bond between the fin and the tube is typically created through high-frequency welding or tension-wrapping, ensuring a seamless path for heat to travel from the tube wall out to the fins.

How Spirals Revolutionize Heat Transfer

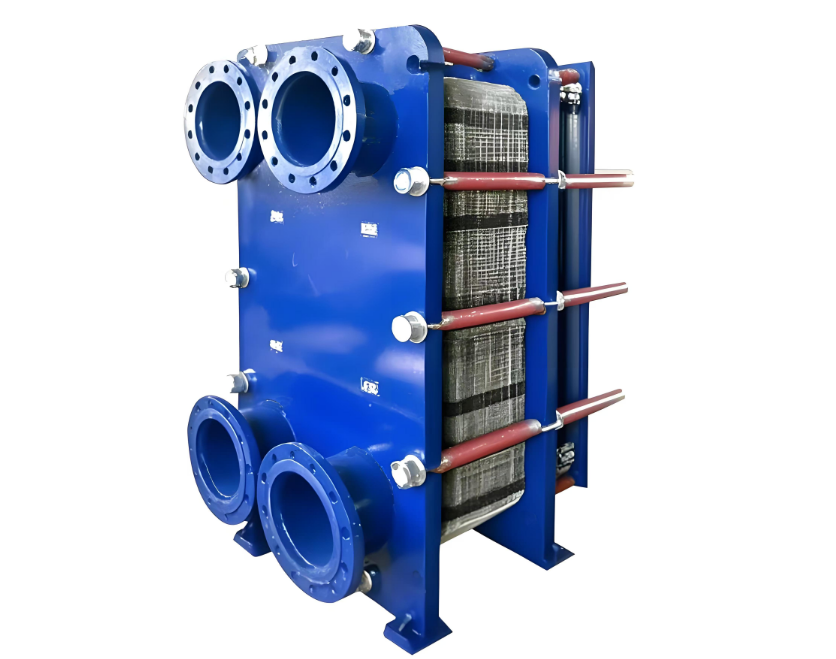

The primary function of a Fin Tube Heat Exchanger is to facilitate the transfer of thermal energy from one fluid to another without them mixing. The genius of the spiral design lies in how it manipulates fluid dynamics. As an external fluid, like air or gas, flows over the Spiral Fin Tubes, the fins guide it into a swirling, turbulent path. This turbulence breaks up the stagnant boundary layer of fluid that typically insulates the tube surface, significantly reducing thermal resistance. The vastly expanded surface area provided by the fins then offers a much larger playground for convection to occur, allowing heat to dissipate into the external fluid stream far more rapidly and effectively than with a bare tube.

Key Industrial Applications

The superior performance of spiral fin technology makes it indispensable in several key sectors. In the power generation industry, they are essential components used as Boiler Tubes. Specifically known as Spiral Tubes for Boilers, they line the walls of water-tube boilers to absorb the maximum amount of heat from combustion gases, efficiently turning water into high-pressure steam. Another critical application is within the Petrochemical Heat Exchanger. In refineries and chemical plants, these tubes are used to heat or cool process fluids, control reaction temperatures, and recover waste heat. Their durability and efficiency are vital for maintaining stable and safe operations in these high-stakes environments.

A Guide to Selecting the Right Tubes

Choosing the appropriate Spiral Fin Tubes for your system requires careful consideration of several factors. First, evaluate the operating conditions, including maximum temperature and pressure, to select the right base tube and fin materials. Second, consider the properties of the fluids involved; corrosive substances may necessitate specialized alloys. The fin's geometry—its height, thickness, and pitch (the distance between fins)—is another crucial variable. A higher fin density increases surface area but also raises the pressure drop of the fluid flowing across it. The key is to work with an engineering team to find the optimal balance that maximizes heat transfer for your specific application without creating an unacceptable hindrance to fluid flow. This ensures you get a solution tailored for peak performance and long-term reliability.