Understand fin tube radiator

Fin tube radiator is an important innovation in the field of heat transfer systems. These radiators are designed to increase thermal efficiency by using fins to increase surface area, thus making them essential in a variety of industrial and commercial applications. But, what exactly is a fin tube radiator? In short, this is a heat exchanger that utilizes tubes with attached fins to maximize the effectiveness of heat dissipation or absorption. This advanced design is essential for optimizing energy efficiency while ensuring reliable operation in demanding environments.

Design and Functions of Fin Tube Radiator

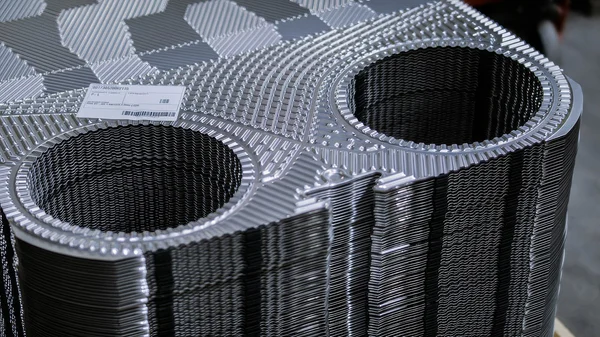

The fin radiator design is built around the idea of maximizing heat transfer efficiency. By combining fins around the oil pipe, the radiator provides an additional surface area for the heat exchange process. Whether used in HVAC systems, industrial chillers or chemical processing plants, fin tube radiators are customized to meet specific system needs. Using materials such as copper in pipes enhances conductivity, while finishes such as blue aluminum fins contribute to the durability and effectiveness of the device. This simplified design allows the radiator to operate seamlessly in a compact space, which is a limited installation, such as a retrofit scenario.

Application of Fin Tube Radiator

The fin tube radiator application has extremely many uses. In industrial environments, they play an important role in regulating heat in processes such as distillation, refrigeration, and chemical synthesis. They are also often found in HVAC systems, where they ensure optimal temperature control and energy efficiency. The adaptability of the fin heating system to a variety of flow arrangements, such as countercurrent and parallel flow, makes them suitable for a variety of operating requirements. Regardless of location or purpose, these radiators can provide unparalleled performance and reliability, demonstrating their effectiveness in modern heat transfer technologies.

Benefits and installation of fin tube radiator

One of the main benefits of fin tube radiators is their energy efficiency. By leveraging advanced thermal technologies, they can greatly reduce energy consumption, making them an environmentally friendly choice for businesses designed to be sustainable. Their compact design not only saves space, but also simplifies installation and facilitates system integration. Customizable connectors further simplify the fin tube radiator installation process, which facilitates seamless integration into existing duct systems. This ensures a hassle-free upgrade or implementation for facilities requiring high-performance heating or cooling solutions.

Industrial uses and efficiency

Industrial fin tube radiators are the cornerstone of departments that require precise thermal control. When paired with equipment such as compact industrial condensers, these radiators expand their effectiveness by working together to optimize the heat exchange rate. The efficiency provided by these systems enables the industry to maintain consistent temperature control with minimal energy input, ensuring reduced operating costs and extended equipment life. Their powerful construction (with protective coatings and stainless steel casing) ensures that they can withstand harsh environments without damaging performance.

Reliable solutions for heat transfer systems

If you are considering upgrading an industrial setup or implementing a new heat transfer system, the fin tube radiator provides an excellent solution. The combination of their efficiency, versatility and durability makes them a reliable choice for various industries. Whether used with cutting-edge products such as compact industrial condensers or as a standalone heating system, fin tube radiators will have unrivalled reliability and energy saving advantages. For businesses seeking innovation without damaging space or costs, these radiators are a small powerhouse that can achieve great results.

![[Wuxi Tenghao Machinery ] - Leading Manufacturer of Industrial Heat Exchangers](https://ptwebimg.pinshop.com/i/2025/05/29/e7pb3m-3.jpg)