A modern industrial facility relies on countless complex processes, and at the heart of many of them is the humble yet critical heat exchanger. This device is fundamental to thermal management, enabling the efficient transfer of heat between two or more fluids. From power generation to chemical processing, its role is indispensable for maintaining operational efficiency, safety, and cost-effectiveness. The principles behind it are foundational to thermodynamics, but the engineering involved elevates it to a marvel of industrial design.

Understanding Industrial Heat Exchangers

When we talk about industrial heat exchangers, we refer to robust systems designed to withstand demanding conditions such as high pressures, extreme temperatures, and corrosive environments. Their primary function is to manage heat in large-scale applications, whether it's cooling a process fluid, heating a liquid with steam, or recovering waste heat. A key example of this powerful technology is the shell and tube design, renowned for its versatility and durability in various sectors, including energy production and refrigeration systems. These devices are the workhorses that ensure processes run smoothly and efficiently.

A Deep Dive into Shell and Tube Heat Exchangers

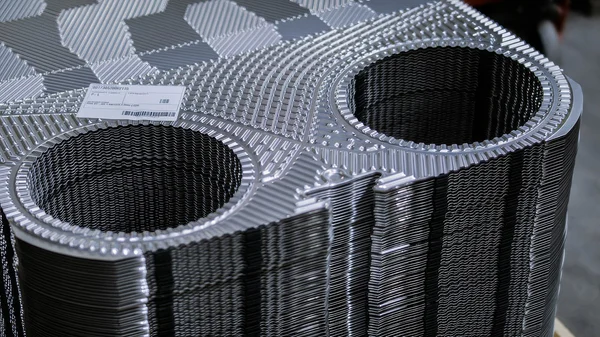

Among the various types, shell and tube heat exchangers stand out for their robust construction and high-performance heat transfer capabilities. This design features a bundle of tubes housed within a larger cylindrical shell. One fluid flows through the tubes while another flows over the tubes within the shell, facilitating efficient thermal exchange. The tubes are often crafted from materials like SA179, chosen for its high thermal conductivity and durability. This configuration is exceptionally effective for both steam-to-liquid and liquid-to-liquid heat transfer, making it a versatile solution for countless applications. The reliability of this design ensures stable temperature control, which is crucial for sensitive industrial processes.

The Power of Customization and Advanced Design

Not all industrial processes are the same, which is why custom heat exchangers are in high demand. An expert heat exchanger manufacturer can tailor every aspect of the device to meet specific project requirements. This includes customizing tube diameters, lengths, materials, and even the shell dimensions for either horizontal or vertical setups. For instance, the fins on the tubes can be engineered with an L-shaped or embedded structure, with precise spacing to maximize the surface area for heat transfer while minimizing pressure drop. With tube thickness options like 2.77 mm, these units can handle significant pressure, and specialized materials can provide long-term corrosion resistance in harsh chemical environments, ensuring a long service life.

Enhancing Efficiency with Heat Recovery Systems

One of the most significant benefits of modern thermal management is its contribution to sustainability through heat recovery systems. An efficient heat exchanger is the core component of these systems, capturing waste heat from one industrial process and repurposing it for another. This directly translates to substantial energy conservation and lower operational costs. By reducing thermal losses and optimizing energy use, these systems not only improve a company's bottom line but also help them embrace more sustainable practices. This focus on energy savings empowers enterprises to reduce their environmental footprint without compromising on production efficiency or performance.

Selecting the Right Partner and Technology

Choosing the right equipment and provider is paramount for ensuring long-term success. Reputable heat exchanger suppliers offer a range of solutions, from the versatile shell and tube heat exchangers discussed here to other efficient designs like plate heat exchangers. A knowledgeable supplier will work with you to understand your operational needs and recommend or design a system that delivers optimal performance and reliability. Whether you need a standard unit or a fully custom solution for a complex application, the right partner ensures your investment enhances productivity and stands the test of time.

![[Wuxi Tenghao Machinery ] - Leading Manufacturer of Industrial Heat Exchangers](https://ptwebimg.pinshop.com/i/2025/05/29/e7pb3m-3.jpg)