In demanding industrial sectors like Oil & Gas, Chemical Processing, and Power Generation, managing thermal energy effectively presents a significant challenge. The need to transfer heat between fluids under conditions of high pressure, extreme temperatures, and corrosive environments can lead to operational inefficiencies and costly downtime. The ultimate solution to this widespread problem is the robust and versatile shell and tube heat exchanger, an engineering marvel designed to provide reliable and efficient performance where other systems fall short.

Why Design is Critical in Industrial Heat Exchange Systems

The success of any thermal process hinges on the quality of the underlying heat exchanger design. A subpar design can result in poor thermal transfer, unexpected pressure drops, and even critical safety failures. For heavy-duty applications, a design that complies with rigorous industry standards like TEMA (Tubular Exchanger Manufacturers Association) and ASME (American Society of Mechanical Engineers) is not just a feature but a fundamental requirement. These standards ensure the unit's structural integrity and its ability to withstand intense operational demands consistently. An effective approach to industrial heat exchange systems involves a holistic design process that considers fluid dynamics, thermal conductivity, and mechanical stress to create a balanced, high-performance unit that integrates seamlessly into the larger operation.

Material Selection and Its Impact on Thermal Performance Heat Exchangers

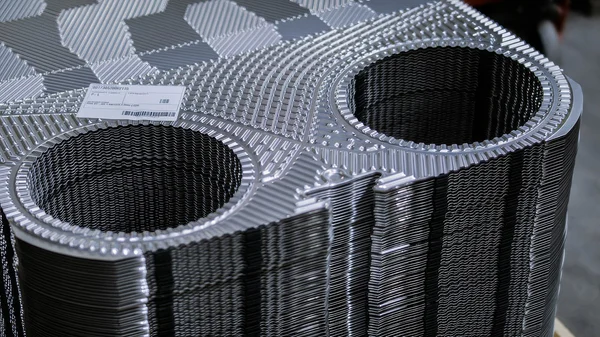

Beyond the initial design, the materials used in construction are paramount to ensuring long-term reliability and optimal function. The heart of any tube heat exchanger is its bundle of tubes, which must be resilient against corrosion, fouling, and thermal stress from the process fluids. The selection of materials, ranging from durable Carbon Steel and Stainless Steel to specialized alloys like Duplex, Titanium, or Copper Nickel, is a strategic decision based on the specific chemical composition and temperature of the fluids being handled. This careful material selection is what guarantees superior thermal performance heat exchangers, preventing premature wear and maintaining efficiency over the unit’s lifespan. The integrity of the shell, tube sheets, and baffles further contributes to a system built for endurance in the harshest industrial settings.

The Role of Precision in Heat Exchanger Manufacturing

A world-class design and premium materials are only as good as the manufacturing process that brings them together. The precision involved in heat exchanger manufacturing—from drilling tube sheets with exacting accuracy to carefully spacing support baffles and executing flawless welds—directly impacts the exchanger's operational efficiency and longevity. For instance, baffles must be positioned perfectly to promote fluid turbulence for enhanced heat transfer while simultaneously minimizing tube vibration that could lead to mechanical failure. Every component, from the nozzles to the support saddles, must be fabricated and assembled with meticulous attention to detail. This commitment to quality craftsmanship is what transforms an engineered blueprint into a dependable industrial heat exchanger capable of anchoring the most critical processes.

![[Wuxi Tenghao Machinery ] - Leading Manufacturer of Industrial Heat Exchangers](https://ptwebimg.pinshop.com/i/2025/05/29/e7pb3m-3.jpg)