The Core of Modern Food Safety: The Pasteurization Unit

A modern Pasteurization unit is a cornerstone of the food and beverage industry, ensuring both product safety and quality. This sophisticated piece of food processing equipment is indispensable for producers of milk, juice, and other liquid products, safeguarding consumers by eliminating harmful pathogens. The evolution of this technology has led to systems that are not only highly effective but also incredibly efficient, preserving the nutritional value and taste of the final product. Understanding the components and principles behind this technology reveals why it is a critical asset in any production line.

Understanding Advanced Pasteurization Technology

At the heart of many modern systems is High-Temperature Short-Time (HTST) Pasteurization technology. This method involves rapidly heating the product to a high temperature, typically 72°C (161°F) for milk, and holding it for just 15 seconds before quickly cooling it down. This brief but intense thermal process effectively neutralizes microorganisms without significantly altering the product's flavor or nutritional profile. This precision is made possible through advanced heat transfer systems that ensure uniform heating and cooling, representing a significant leap in food pasteurization techniques that prioritize both safety and sensory quality.

Designed for Purity: Construction and Materials

The physical construction of a top-tier Pasteurization unit is a testament to engineering designed for ultimate hygiene. These units are typically crafted from high-grade, corrosion-resistant stainless steel, such as AISI 316L, to withstand high temperatures and rigorous cleaning cycles. The internal surfaces are polished to a sanitary finish to minimize bacterial adhesion and simplify cleaning. Furthermore, system components like gaskets are made from FDA-approved, food-grade elastomeric materials. This meticulous design ensures that every part of the thermal processing equipment meets the strictest sanitary standards, preventing any risk of contamination during operation.

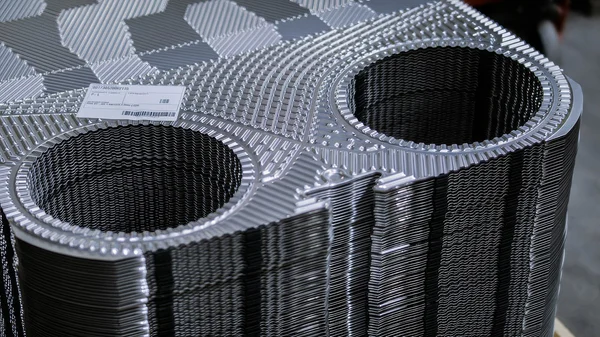

The Engine of Efficiency: Industrial Heat Exchangers

A critical component responsible for the system's efficiency is the plate heat exchanger. These industrial heat exchangers are masterfully designed with a series of corrugated stainless steel plates that create a large surface area for heat exchange. In a pasteurization system, this allows for rapid and efficient transfer of thermal energy between the product and the heating or cooling medium. Often, these heat transfer systems incorporate a regenerative section, where the incoming cold product is pre-heated by the outgoing hot, pasteurized product. This brilliant design significantly reduces energy consumption, making the process more sustainable and cost-effective for large-scale production.

Meeting and Exceeding Industry Standards

For any piece of food processing equipment, adherence to industry standards is non-negotiable. Leading pasteurization systems are fully compliant with rigorous certifications like the 3-A Sanitary Standards and often follow EHEDG (European Hygienic Engineering & Design Group) guidelines. These certifications are a guarantee of impeccable hygienic design, from crevice-free joints to fully drainable systems that eliminate potential points for bacterial growth. This commitment to certified safety provides producers with peace of mind and builds consumer trust in the final product's purity and integrity.

A Critical Investment in Food Production

In conclusion, investing in an advanced Pasteurization unit is an investment in safety, efficiency, and quality. From its sophisticated Pasteurization technology and the crucial role of the heat exchanger to its hygienic construction and certified compliance, every element is designed to meet the demands of the modern food industry. This essential thermal processing equipment is more than just a machine; it is a fundamental pillar supporting the integrity of food production and the trust of consumers worldwide, making it an indispensable asset for any forward-thinking company.

![[Wuxi Tenghao Machinery ] - Leading Manufacturer of Industrial Heat Exchangers](https://ptwebimg.pinshop.com/i/2025/05/29/e7pb3m-3.jpg)