An Industrial Evaporator is a critical piece of equipment used across numerous sectors, from food processing and pharmaceuticals to chemical manufacturing and waste management. At its core, the primary function of an Evaporator System is to concentrate a solution by boiling off a solvent, typically water. This seemingly simple task involves sophisticated engineering to maximize efficiency, ensure product quality, and minimize operational costs. The effectiveness of any Industrial Evaporation Process hinges on its design, an aspect that has seen significant innovation over the years, leading to a variety of specialized systems tailored to specific industrial needs.

The Heart of the System: Heat Transfer Evaporators

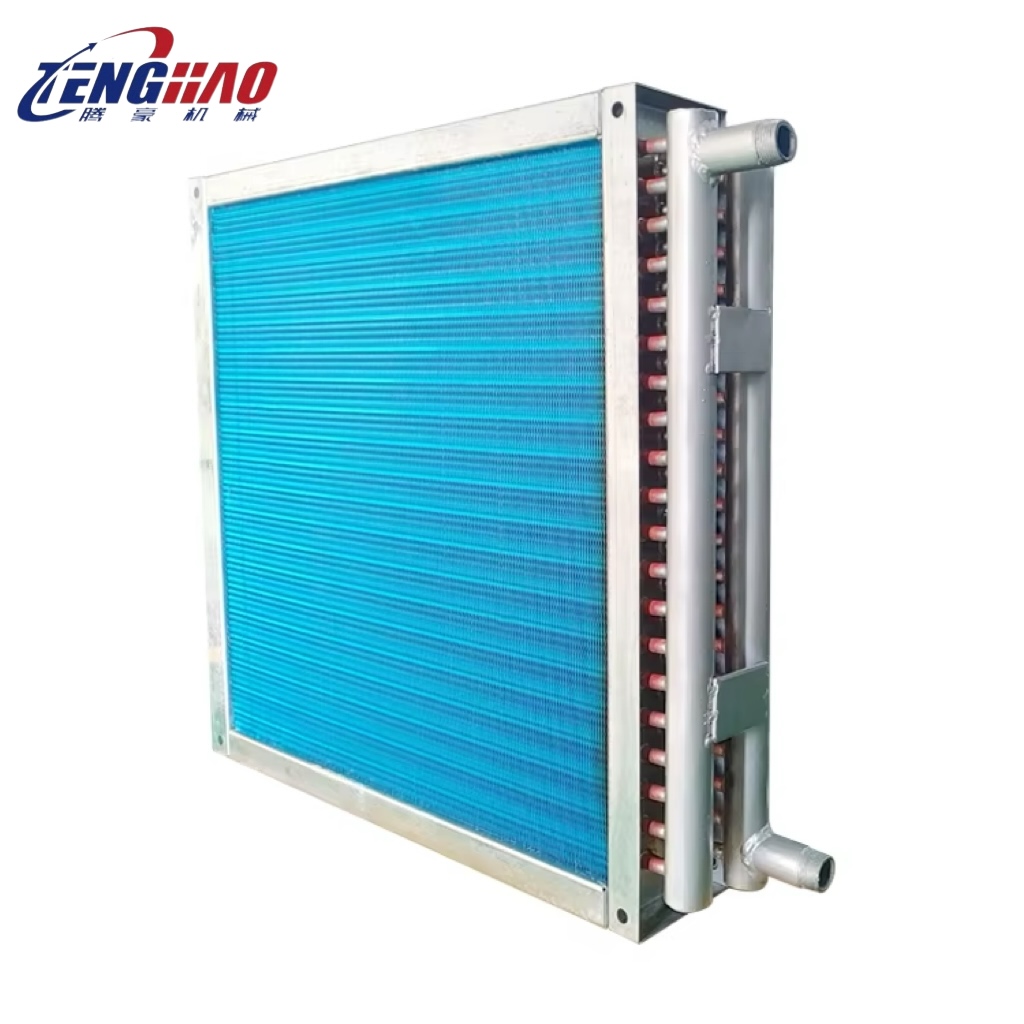

The performance of any evaporator is fundamentally linked to its capacity for heat exchange. Modern Heat Transfer Evaporators are marvels of engineering, designed for superior thermal performance and durability. The construction often involves precision-engineered fins and premium materials like copper tubing for exceptional conductivity, supported by corrosion-resistant stainless steel. For highly aggressive or sanitary environments, materials such as Titanium or Stainless Steel 316L are employed to meet stringent standards from bodies like the FDA and cGMP. Advanced designs focus on maximizing the surface area for heat transfer, which improves efficiency and can significantly reduce the energy required for the evaporation process. Furthermore, features like anti-fouling surfaces and compatibility with Clean-in-Place (CIP) systems ensure that these Heat Transfer Evaporators maintain peak performance with minimal downtime for maintenance.

Continuous vs. Batch Evaporators: Choosing the Right Process

When selecting an evaporator, one of the most fundamental decisions is choosing between a continuous or batch operation. Continuous Evaporators are designed for large-scale, uninterrupted production. In this setup, the feed solution is constantly supplied to the evaporator, and the concentrated product and evaporated solvent are continuously removed. This method is highly efficient for high-volume applications with a consistent feed composition, as it operates at a steady state, allowing for optimized energy recovery and process automation. In contrast, Batch Evaporators process a finite volume of liquid at a time. The entire batch is loaded into the vessel, heated until the desired concentration is reached, and then discharged. While less suited for massive production runs, Batch Evaporators offer superior flexibility. They are ideal for smaller-scale operations, plants that produce multiple different products, or applications where processing is intermittent. Their simpler Evaporator Design often makes them easier to clean and manage between different product runs, a crucial advantage in the pharmaceutical and specialty food industries.

Innovations in Evaporator Design and Technology

The evolution of Evaporator Technology has moved far beyond the basic choice between operating modes. Modern Evaporator Design incorporates advanced features to enhance control, efficiency, and sustainability. Full automation through PLC/SCADA integration allows for precise, remote monitoring of critical parameters like temperature, pressure, and pH, ensuring consistent product quality. Energy efficiency is another key driver of innovation. Techniques like condensate recovery and vapor preheating are now standard in many systems, reducing overall energy consumption. For facilities aiming for sustainability goals like Zero Liquid Discharge (ZLD), advanced systems can achieve remarkable water recovery rates. Additionally, modular, skid-mounted configurations simplify installation and reduce the equipment's physical footprint, making it easier to integrate sophisticated Evaporator Technology into existing plants.

Selecting the Ideal Industrial Evaporation Process

Ultimately, the choice of the right Industrial Evaporator depends on a careful evaluation of process requirements. The decision between Continuous Evaporators and Batch Evaporators is a primary consideration, guided by production volume, product diversity, and operational schedules. For large-scale, single-product manufacturing, a continuous system offers unmatched efficiency. For flexible, smaller-scale, or multi-product needs, a batch system provides the necessary versatility. Beyond this, a modern Evaporator System incorporating advanced Heat Transfer Evaporators, automation, and energy-saving features represents a strategic investment, delivering a more sustainable and cost-effective Industrial Evaporation Process that meets the demands of today's competitive landscape.