In the modern food industry, ensuring product safety and quality is paramount. A state-of-the-art Pasteurization unit is the cornerstone of this commitment, offering a reliable method for enhancing shelf life and eliminating harmful microorganisms through advanced Food pasteurization techniques. This essential process safeguards consumer health and upholds brand reputation by delivering consistently safe and high-quality products, from dairy to juices and beyond.

Understanding the Heart of Food Pasteurization Technology

At its core, Pasteurization technology is a precise form of thermal processing designed to make food safe for consumption without significantly compromising its nutritional value or flavor. This process relies on sophisticated Thermal processing equipment to heat the product to a specific temperature for a set duration, then rapidly cool it. This controlled cycle is what deactivates spoilage enzymes and destroys vegetative bacteria, making it an indispensable step for countless products. The precision involved ensures that while pathogens are eliminated, the delicate characteristics of the product, such as taste and texture, are preserved, which is critical for consumer satisfaction.

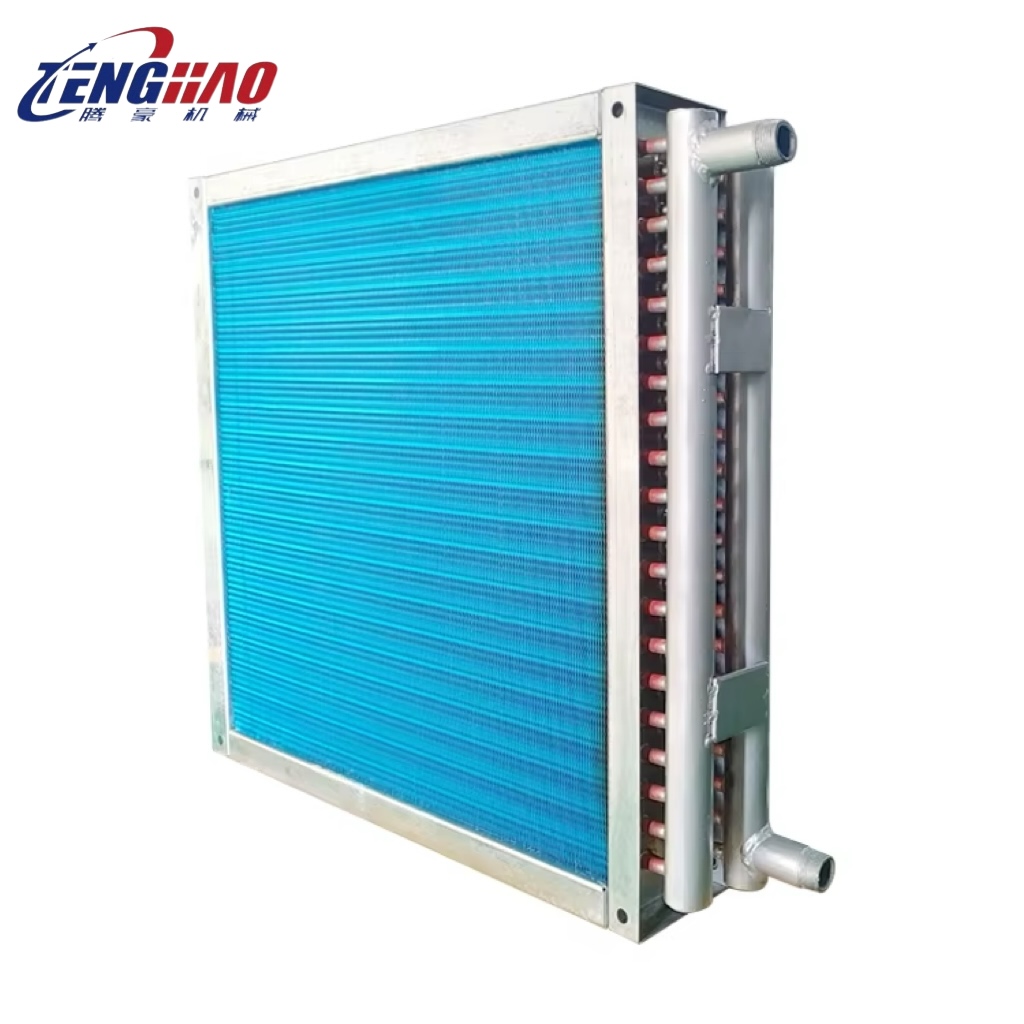

The Role of the Heat Exchanger in Efficient Pasteurization

The engine driving the entire process is the Heat exchanger. Modern systems predominantly utilize plate heat exchangers, which consist of a series of corrugated metal plates that create complex channels for the product and the heating or cooling media. This innovative design maximizes the surface area for heat exchange, resulting in exceptional efficiency and precise temperature control. These advanced Heat transfer systems are a significant leap forward from older methods, allowing for gentle product handling and minimizing energy consumption. This makes them a vital and cost-effective piece of any modern Food processing equipment lineup, directly impacting the operational bottom line.

Innovations in Modern Thermal Processing Equipment

Today’s leading pasteurization systems incorporate features engineered for maximum hygiene, efficiency, and ease of use. Full compatibility with automated Clean-In-Place (CIP) and Steam-In-Place (SIP) procedures is now a standard, ensuring thorough, repeatable cleaning without the need for time-consuming manual disassembly. The plate design itself is highly engineered, often with herringbone patterns that create turbulence to maximize heat transfer while preventing product fouling. Furthermore, features like tool-free access frames, robust corrosion-resistant construction, and sanitary Tri-Clamp connections ensure that the equipment not only meets but exceeds stringent food safety standards like 3-A and EHEDG, while offering exceptional longevity and low maintenance requirements.

Selecting the Right Industrial Heat Exchangers for Your Needs

When choosing a Pasteurization unit, it's crucial to look beyond the basic specifications. The best Industrial heat exchangers are highly customizable to handle specific product viscosities, flow rates, and processing requirements. Value-added options such as integrated leak detection systems, form-fitting insulation jackets for energy conservation, and specialized plate coatings allow businesses to tailor the equipment to their precise operational needs. Investing in a high-quality system with a reliable Heat exchanger is not merely an operational expense; it is a strategic decision that protects your brand, assures consumer safety, and optimizes production efficiency for a greater and faster return on investment.

Elevate Your Production with Cutting-Edge Pasteurization

Ultimately, adopting advanced Pasteurization technology is about future-proofing your operations and elevating your product quality. By leveraging superior Food processing equipment, you can confidently deliver products that are not only safe but also maintain their intended flavor, texture, and nutritional profile. These systems provide the control, reliability, and efficiency necessary to compete and thrive in a demanding global market. Making the right choice in your thermal processing setup is a direct and powerful investment in your product's integrity and your company's lasting success.