Understanding the Core of Industrial Thermal Management

A shell and tube heat exchanger is a cornerstone of modern industry, serving as a critical component in countless processes that require efficient heating or cooling. These robust devices are fundamental to the operation of many industrial heat exchange systems, enabling the transfer of thermal energy from one fluid to another without allowing them to mix. Whether in oil refineries, chemical plants, or power generation facilities, understanding the principles behind this technology is key to optimizing operations. A proper heat exchanger design ensures not only efficiency and reliability but also the safety and longevity of the entire system it serves.

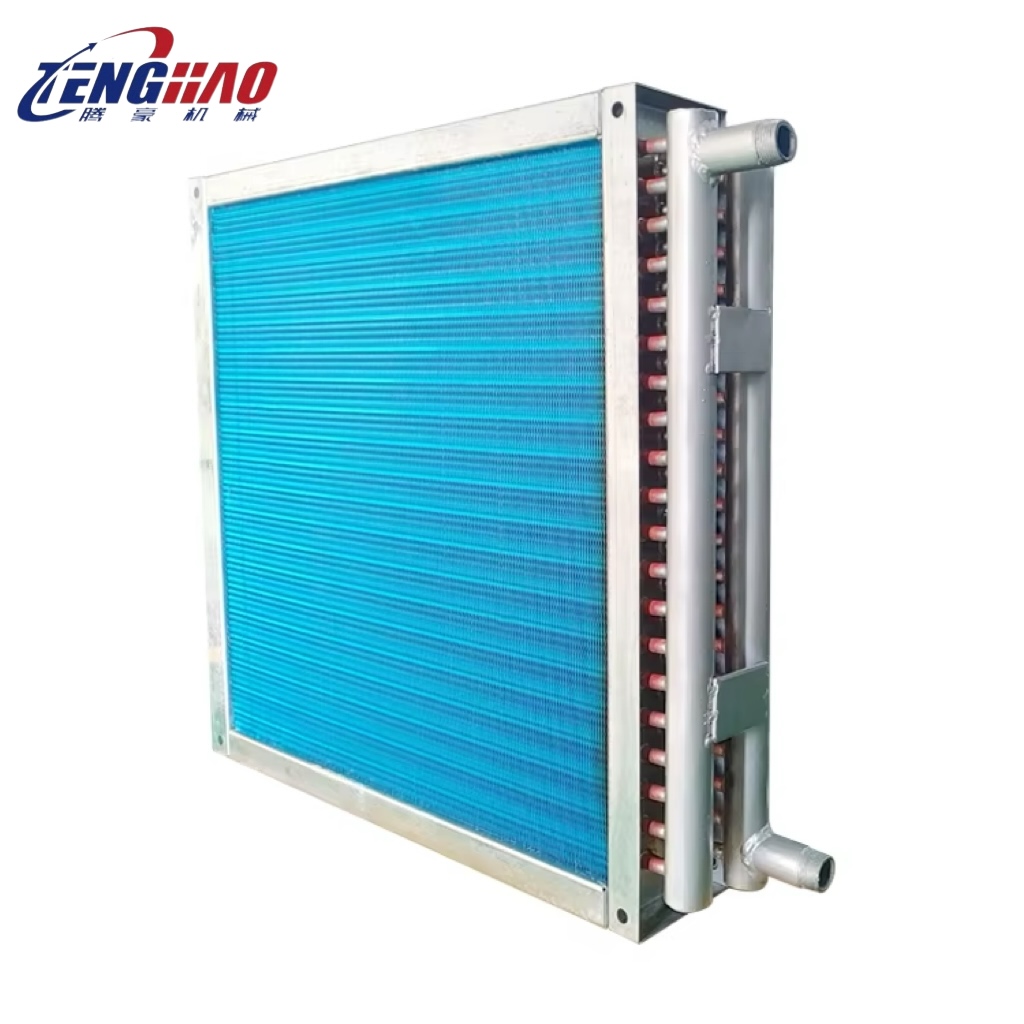

Decoding the Anatomy: Key Components and Design Principles

At its core, the design of a tube heat exchanger is elegantly simple yet highly effective. It consists of a large cylindrical shell that encloses a bundle of tubes, known as the tube bundle. One fluid flows through these tubes, while a second fluid circulates within the shell, around the exterior of the tubes. The heat is transferred through the tube walls. Key components like tube sheets, baffles, and channels direct the flow and support the structure. Baffles, for instance, are strategically placed to guide the shell-side fluid across the tube bundle, which increases turbulence and maximizes the heat transfer rate. Designs like the Fixed Tube Sheet (FTS) configuration are popular due to their structural simplicity, cost-effectiveness, and reliability in high-pressure and high-temperature environments, making them a go-to choice for many applications.

A Guide to Evaluating Thermal Performance

When selecting or designing a unit, the primary goal is to maximize thermal performance. The thermal performance of heat exchangers is measured by several key indicators. Heat Duty refers to the total amount of heat the unit can transfer in a given time. The Log Mean Temperature Difference (LMTD) and the Overall Heat Transfer Coefficient (U-value) are critical calculations that determine the exchanger's efficiency in bridging temperature gaps between the two fluids. Another practical concern is fouling resistance, which is the ability to maintain performance despite the gradual buildup of deposits on heat transfer surfaces. Advanced features like finned tubes can significantly amplify the surface area for heat transfer, while multi-pass flow paths, created by partition plates, recirculate fluids to extract or dissipate more thermal energy.

From Blueprint to Reality: The Manufacturing Process

The process of heat exchanger manufacturing is governed by stringent standards to ensure safety, durability, and performance. Reputable fabrication follows codes like ASME Section IX, which dictates welding procedures and qualifications. To guarantee structural integrity, finished units undergo a series of Non-Destructive Testing (NDT) inspections, including Radiography, Ultrasonic, and Dye Penetrant tests, which can identify microscopic flaws invisible to the naked eye. For applications involving extreme thermal stress, a Post-Weld Heat Treatment (PWHT) may be applied to relieve residual stresses in the material, enhancing its resilience. Details like tube-to-tubesheet joints, which are often both welded and expanded, provide a robust, leak-proof seal that can withstand thermal expansion and contraction.

Where They Work: Common Applications for Shell and Tube Heat Exchangers

The versatility of the shell and tube heat exchanger makes it a ubiquitous piece of equipment across numerous sectors. As a premier industrial heat exchanger, it is indispensable in the oil and gas industry for processes like amine cooling and process gas conditioning. In marine environments, these units are often used as seawater coolers, built with corrosion-resistant materials to withstand the harsh conditions. You will also find them in large-scale utility systems, such as HVAC chiller condensers and steam surface condensers for power plants. Each application demands a slightly different configuration, but the fundamental principles of reliable and efficient heat transfer remain the same, making this a truly adaptable technology.