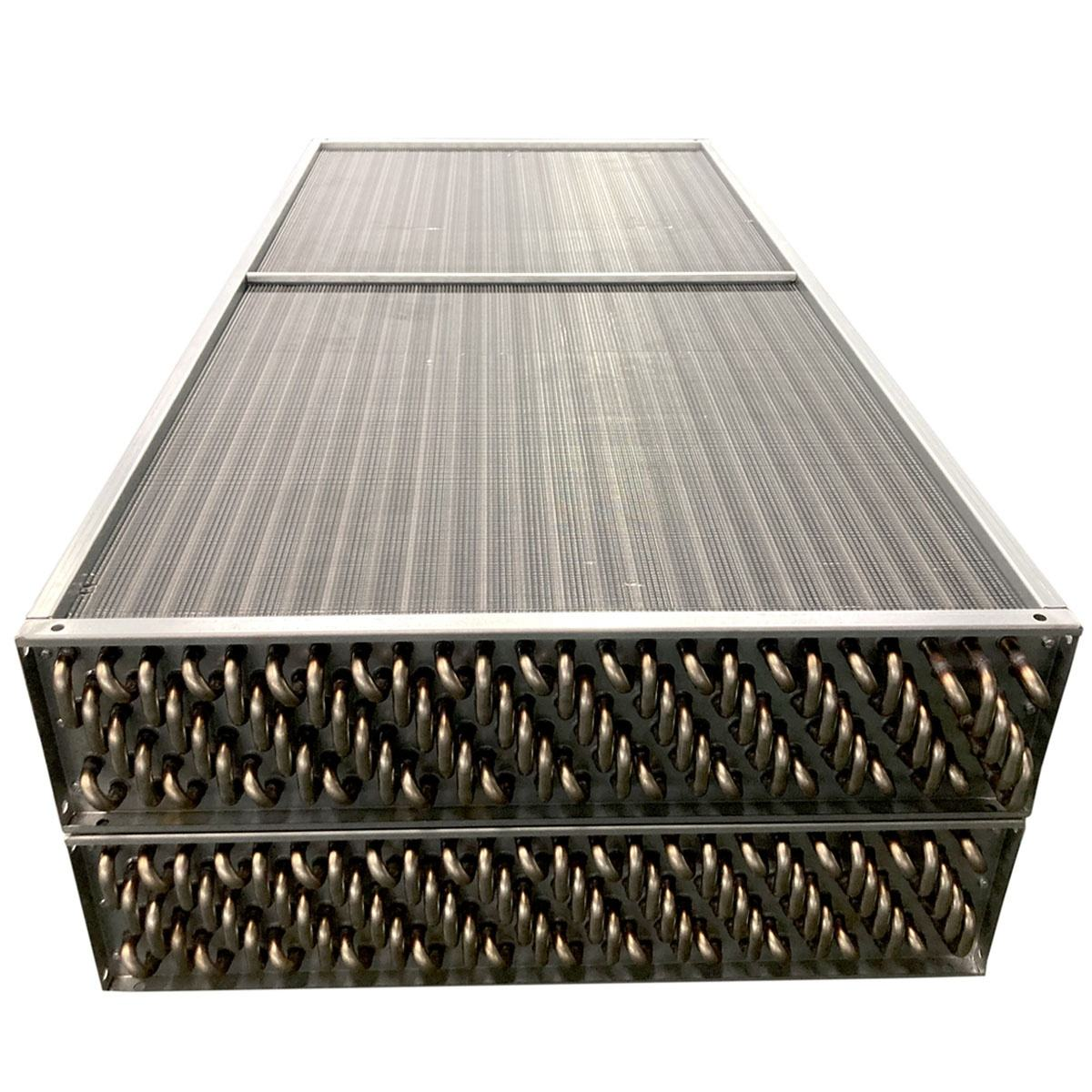

Understand the Fin Tube Heat Exchanger

Fin tube heat exchangers represent an important advance in the industrial process and are known for their effective heat transfer capabilities. These systems are an important part of energy-saving strategies, especially in sectors where temperature regulation is critical. By enhancing the surface area of heat dissipation or absorption, the fin tube heat exchanger manages thermodynamics more efficiently than non-primed. Their versatile design makes it suitable for a variety of applications, including HVAC systems, power plants and industrial wastewater recycling solutions, such as innovative RTO waste heat exchangers.

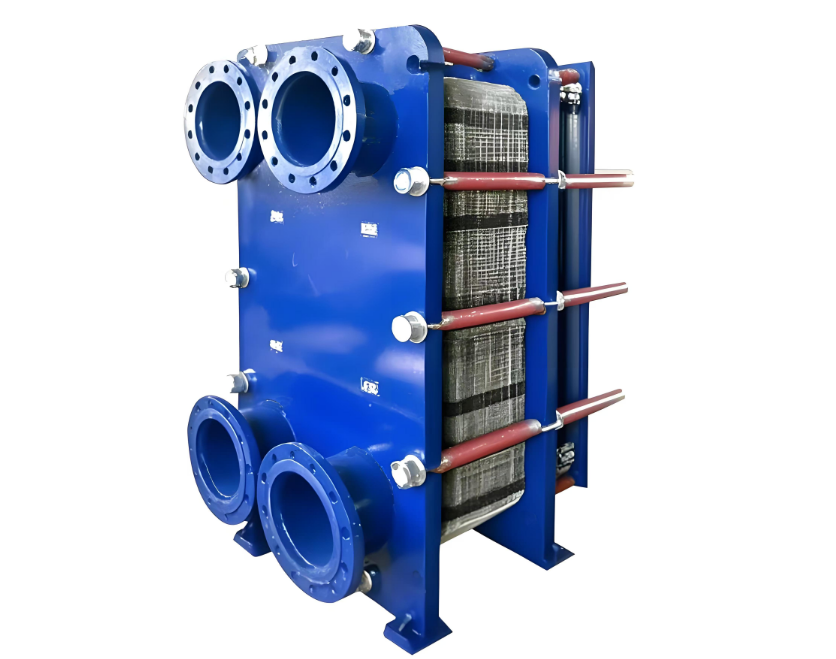

Introducing RTO waste heat exchanger

RTO waste heat exchangers are a state-of-the-art solution designed to optimize energy efficiency in industrial environments. The unit is made of high-quality stainless steel for durability and modern aesthetic appeal. Custom-made for regenerative thermal oxidants (RTOs), it excels in leveraging residual heat generated during industrial operations, reducing energy costs and reducing environmental impact.

The polished surface of the exchanger can not only withstand corrosive conditions typical in industrial processes, but also simplify maintenance. Its layout features strategically placed inlet ports marked "Heat Out" (Heat) and "Cool In" (Cool In) to facilitate direct installation and maximize thermal recovery. These innovations are crucial for industries that strive to adhere to strict ecological standards, thus greatly reducing their carbon footprint.

Innovative design and functions

What makes the RTO waste heat exchanger unique is its excellent engineering that ensures minimal heat loss, thus keeping the industry peak operational efficiency. The unit embodies the perfect combination of form and function, enabling seamless integration with existing systems. This integration not only enhances existing infrastructure, but also improves it, allowing companies to achieve unparalleled energy savings.

In addition, the design of this waste heat exchange helps to efficiently supply heat exchange, ensuring effective utilization of excessive energy rather than waste. The process involving the production of this unit ensures consistent, reliable performance over time, thus making it invested in both sustainability and savings.

Promote environmental responsibility

RTO waste heat exchangers play a key role for companies working to address climate change and promote environmental sustainability. By recapturing and repurposing thermal energy, the device helps reduce greenhouse gas emissions and reduces dependence on fossil fuels.

Completing this with its circular hole design is the unit's ability to handle a lot of heat needs easily. This allows for large amounts of airflow and helps achieve a massive reduction in energy waste, providing the industry with the opportunity to sustainably expand its operations.

Conclusion

RTO waste heat exchangers are more than just components. This proves industrial capacity and environmental management. As the global industry shifts toward more sustainable practices, technology like RTO wastewater exchangers is integrated into essential. By choosing such cutting-edge solutions, businesses not only improve efficiency, but also play a positive role in paving the way for a sustainable future. The embrace of advanced heat exchange solutions, including fin tube design, marks an important step in achieving comprehensive energy efficiency and sustainability goals.