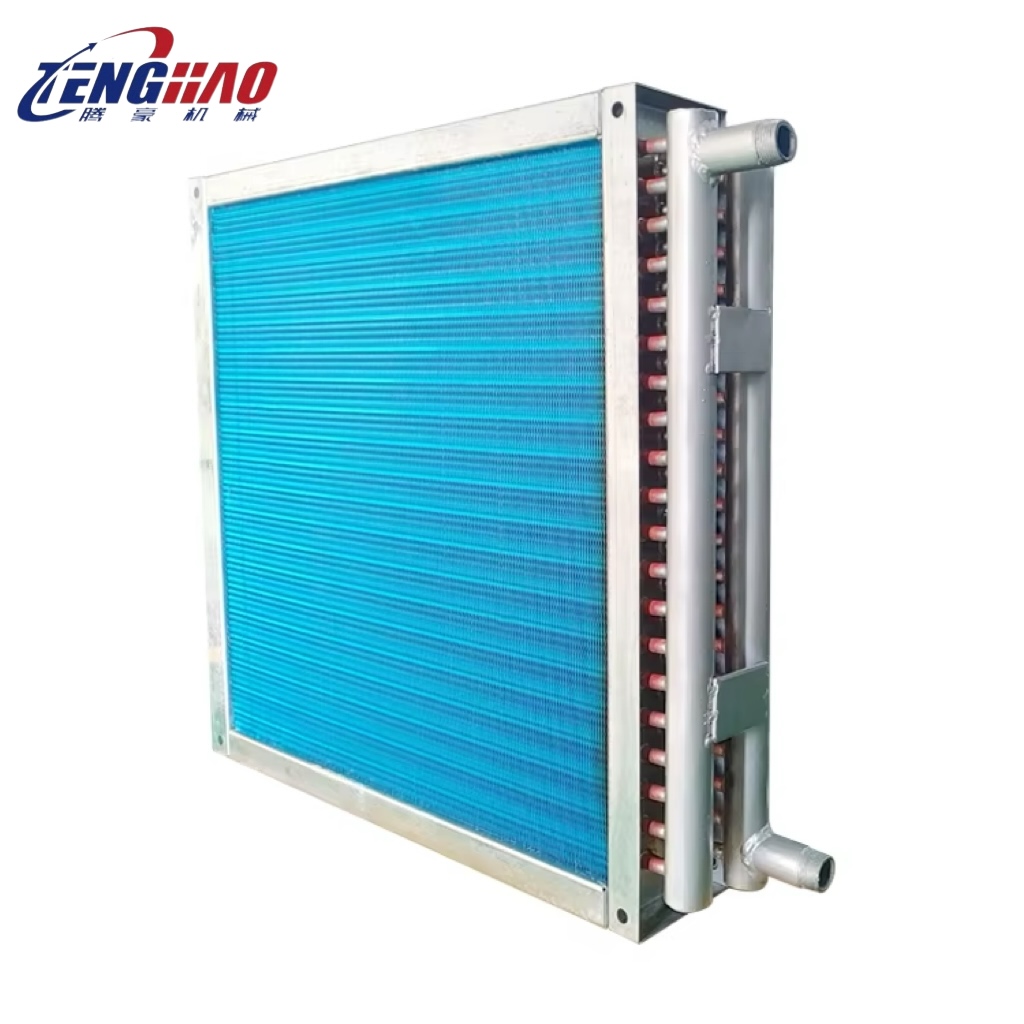

Introduction to high-efficiency board heat exchanger

Plate heat exchangers (PHEs) have become an essential component in the industrial sector, especially for waste heat recovery applications. These high-efficiency PHEs are known for their compact design, excellent thermal performance and cost-effective solutions in heat exchange. Using advanced technology, PHES captures and recycles waste heat from industrial waste gases, achieving significant thermal efficiency, optimizing energy utilization and reducing operating costs.

Unparalleled performance and excellent design

Modern plate heat exchangers are carefully designed to be executed in the most demanding industrial environments to achieve impressive thermal recovery efficiency up to 80% or higher. These PHEs are constructed from advanced materials such as 316L stainless steel, titanium or specialized corrosion-resistant coatings to ensure endurance to corrosive gases and corrosion resistance and high temperature conditions typical in industries such as chemistry, petrochemical and metallurgy. This construction optimizes PHE efficiency while also making a significant contribution to environmental sustainability.

Verifiability and customization

One of the distinctive features of this energy-efficient PHE is its modular design, which provides excellent flexibility for installation and maintenance. Customers can customize the system to meet specific industrial needs; as industrial needs evolve, this modularity ensures easy expansion or modification of system functions. The versatility of the system extends a range of industry applications, provides optimized solutions for a variety of working conditions and facilitates best practices for PHE maintenance.

Intelligent Control System

To further improve PHE efficiency, the system provides an optional PLC automatic control mechanism for real-time monitoring and optimization. The intelligent control system ensures peak efficiency and reliability of thermal recovery operations, thus achieving greater energy protection and operational efficiency. The integration of smart technologies emphasizes the importance of design optimization for innovative and sustainable heat exchange solutions.

Diverable industry applications

The powerful plate-type waste recovery system has found applications in many industries, demonstrating the benefits of compact heat exchangers in various sectors:

- **Power Industry**: It restores waste heat from the flue gas of gas turbines and boilers, helping to preheat combustion air or boiler feed water.

- **Chemical and Petrochemical Industry**: This system captures valuable heat from sulfur-containing and acidic exhaust gases for heating.

- **Metallurgical Industry**: It cools flue gases in high temperature operations, which can greatly reduce energy consumption.

- **Food and Medical Fields**: This system complies with FDA/GMP regulations, making it ideal for processes requiring strict hygiene standards.

The years of professional industry experience, including partnerships with Alfa Laval and Alfa Laval, as well as independent R&D capabilities, position the solution at the forefront of innovation in industrial thermal recovery. The system's technical strength is ISO 9001/14001 certified, ensuring efficiency, durability and reliability in a variety of operating environments.

Verified results and sustainability

The realistic implementation of these flat panel heat exchangers shows that fuel costs are significantly reduced, providing a return on investment in less than two years. Thermal recovery efficiency ranges from 70% to 90%, heat resistance from -20°C to 600°C, and pressure resistance is up to 25 bar. Material options such as 316L, titanium, Hastelloy or Ptfe bushing specific environmental requirements emphasize the robustness of the system. As a commitment to operational excellence for sustainability and industrial thermal recovery, this solution represents technologically advanced and reliable systems in the modern industry.

Conclusion

Using efficient PHE technology is crucial for modern industries that aim to optimize energy utilization, while minimizing environmental impact. The state-of-the-art plate-type waste thermal recovery system embodies innovation, endurance and versatility, making it the first choice for complex industrial applications.