Introduction to Energy Recovery Through Industrial Heat Exchangers

In an era dominated by the need for increased energy efficiency and sustainable practices, рекуперация тепла has become a cornerstone of industrial development. Industrial heat exchangers, particularly those designed for the recovery of heat from промышленные дымовые газы, offer groundbreaking possibilities. By employing advanced рекуператор technology, industries can achieve significant cost savings while taking an eco-friendly approach to energy consumption.

Precision Engineering and Optimal Heat Transfer

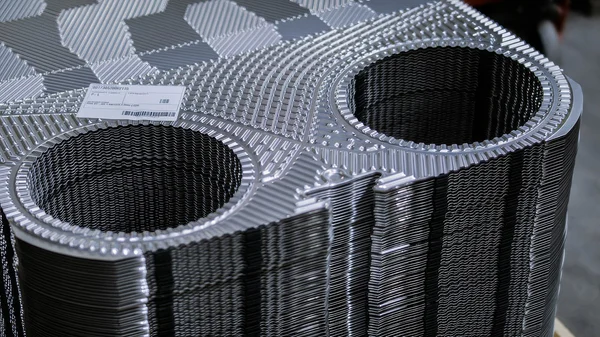

A key component of these devices is their meticulous design, demonstrated through the use of copper tubing and heat transfer surfaces. Copper tubing ensures exceptional thermal conductivity, making it ideal for high-temperature scenarios. Additionally, aluminum fins enhance the heat transfer surface area, ensuring maximum efficiency in devices like устройства рекуперации. This synergy between materials facilitates effective energy recovery and contributes to the device’s overall долговечность.

Durability and Integration into Industrial Systems

The modular stainless steel casing provides robust protection to the internal components, allowing the system to endure harsh industrial environments. This level of durability makes it suitable for industries requiring heavy-duty applications, such as metallurgy and cement processing. Moreover, reinforced connection ports promote seamless integration with промышленные системы вентиляции, ensuring stability even under high-pressure operations.

High Efficiency and Environmental Benefits

The incorporation of advanced leak prevention systems and customizable designs ensures that these devices meet specific industrial needs without compromising their functionality over time. Beyond energy efficiency, they play a vital role in reducing greenhouse gas emissions by utilizing energy previously lost through waste. This advantage aligns well with современные экологические технологии, helping industries maintain compliance with global sustainability goals.

Applications and Benefits Across Industries

From thermal power plants to chemical facilities, the applications of these рекуператор have proven versatile and effective. Metal processing plants and petrochemical refineries especially benefit from the возврат тепла, optimizing operations while minimizing costs. Key advantages include higher энергетическая эффективность, reduced operational expenses, and a notable reduction in the carbon footprint. These factors highlight the importance of adopting modern рекуперация энергии devices for industrial growth and environmental preservation.

Conclusion

As industries continue to evolve, the demand for systems balancing operational efficiency and eco-friendliness grows exponentially. The industrial heat exchanger, engineered with advanced materials and technologies, exemplifies this balance. By investing in these units, businesses can simultaneously optimize their systems’ отопление and contribute positively to global environmental standards. In essence, they are not merely systems for heat recovery but transformative tools shaping the future of industrial energy utilization.

![[Wuxi Tenghao Machinery ] - Leading Manufacturer of Industrial Heat Exchangers](https://ptwebimg.pinshop.com/i/2025/05/29/e7pb3m-3.jpg)